Fluid envelope surface type apparatus for shielding, separating and exhausting powdered smoke dust

A technology of discharging device and enveloping surface, which is applied in the direction of removing smoke and dust, combining device, separating method, etc., can solve the problems of bloated and complicated structure, low effect, unable to form shielding surface, etc., and achieves improvement of working conditions, complete effect and application. Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

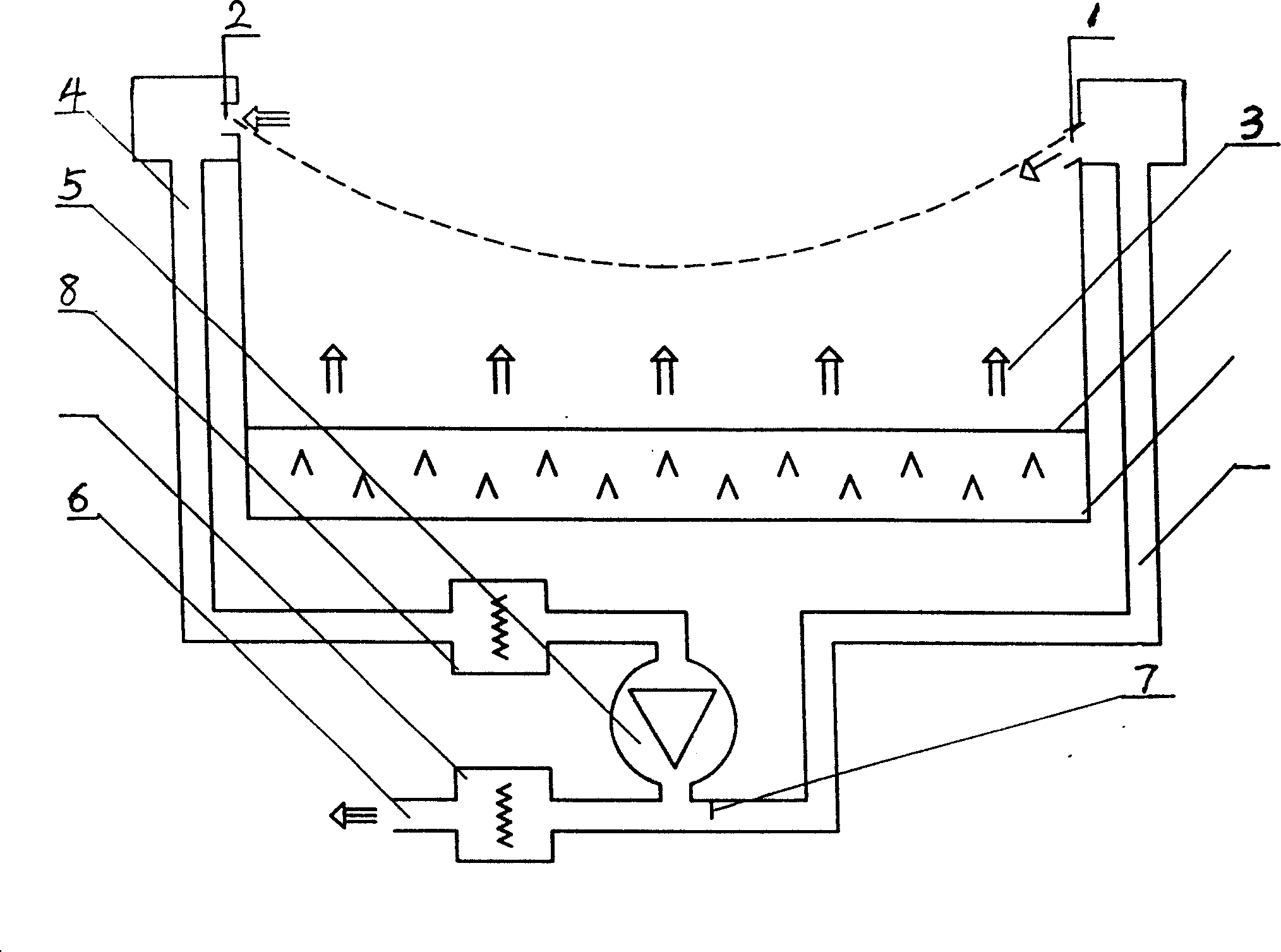

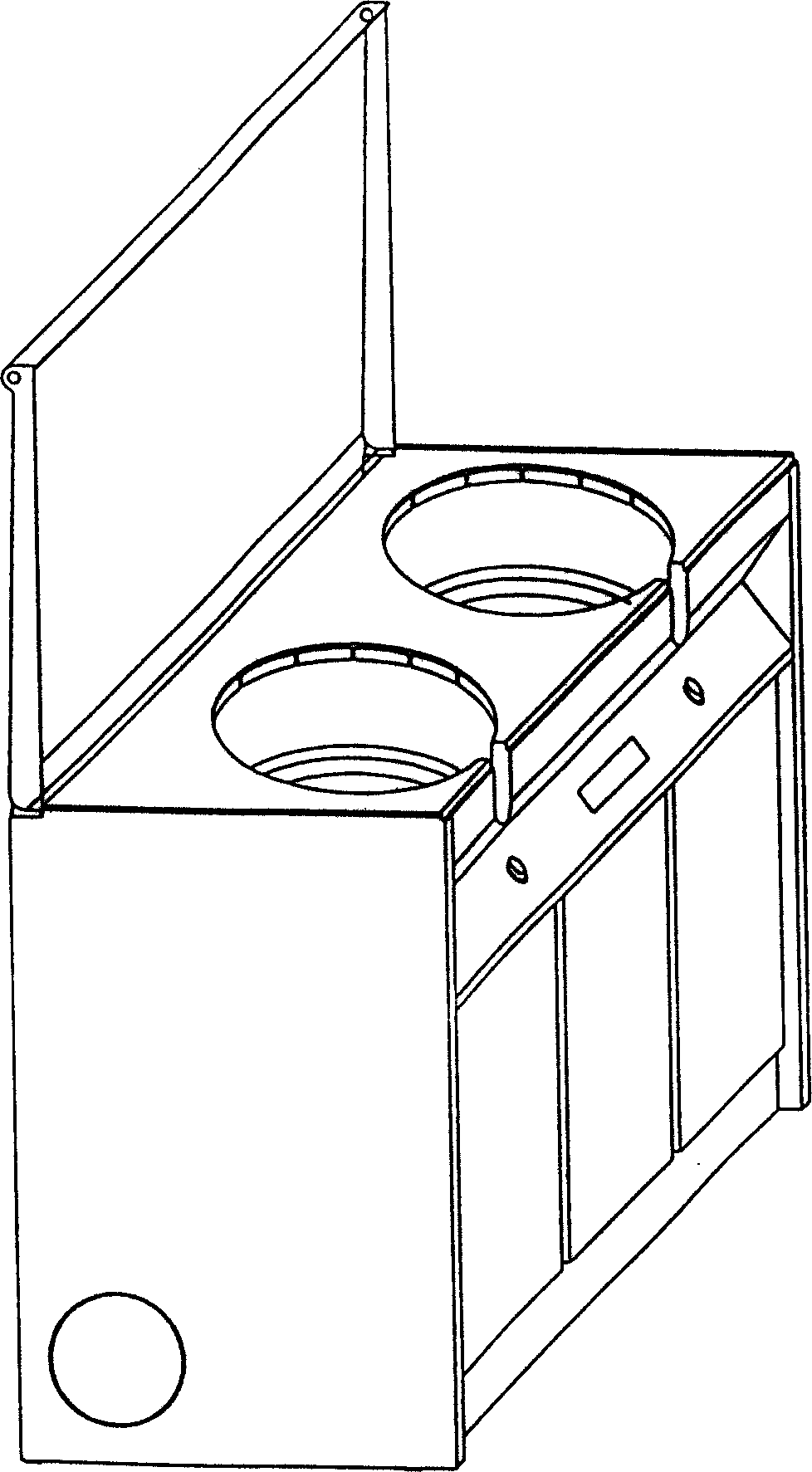

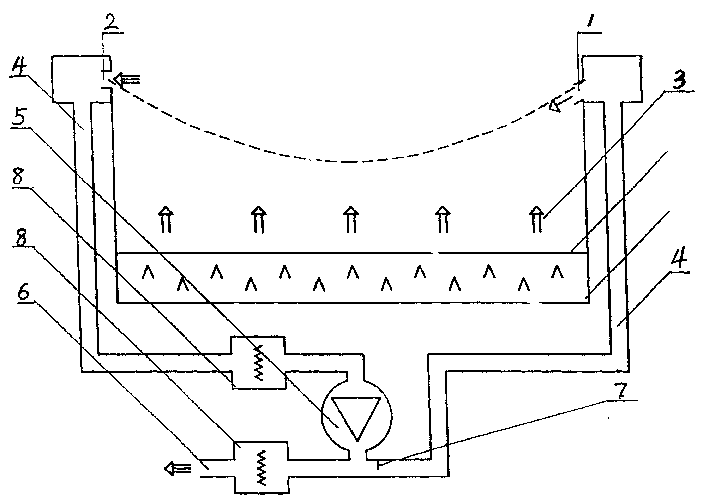

[0027] Further description is made below in conjunction with the accompanying drawings. The fluid envelope type dust shielding separation and discharge device of the present invention is composed of a bracket, a negative pressure air ring generating device, and a positive pressure air generating device, and the negative pressure air ring generating device includes a The superior arc-shaped air inlet 2, the positive pressure wind generating device comprises a inferior arc-shaped air outlet 1, and the air inlet 2 and the air outlet 1 are placed around the diffusion surface 3 of the dyeing source; the air inlet 2 is further connected with a guide air Pipe 4, fan 5 and exhaust pipe 6. The air outlet 1 is inclined toward the diffusion surface 3 of the pollution source. The air outlet 1 and the air inlet 2 share the fan 5, and the air outlet of the fan 5 is connected with an air duct 4 leading to the air outlet 1, and there is an air duct 4 at the connection between the air duct 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com