Automatic dough kneading machine

A dough mixer and automatic technology, which is applied in the direction of mixing/kneading with vertical installation tools, can solve the problems of large investment in building a factory, difficulty in controlling the degree of dough mixing, and affecting the stability of dough performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

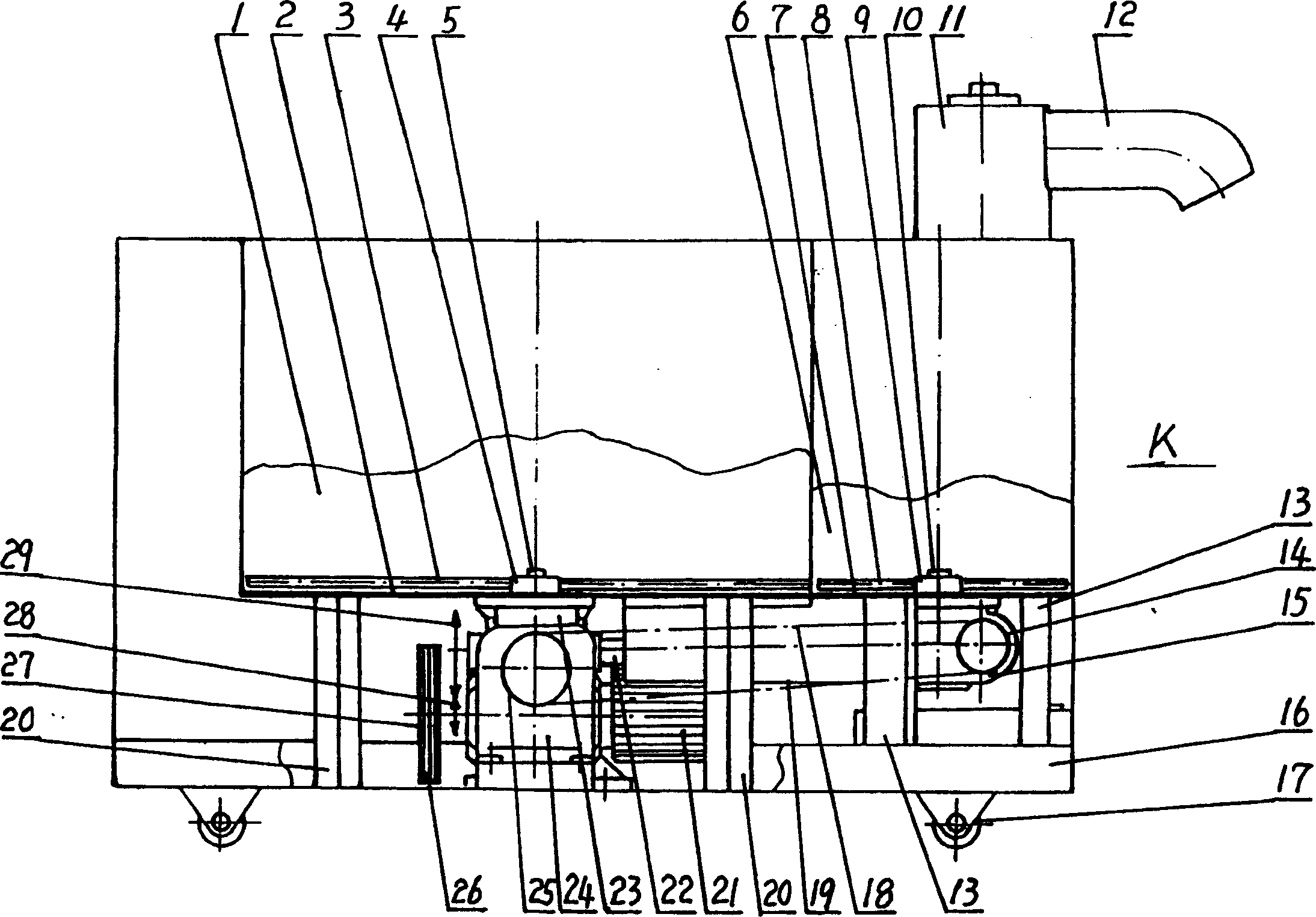

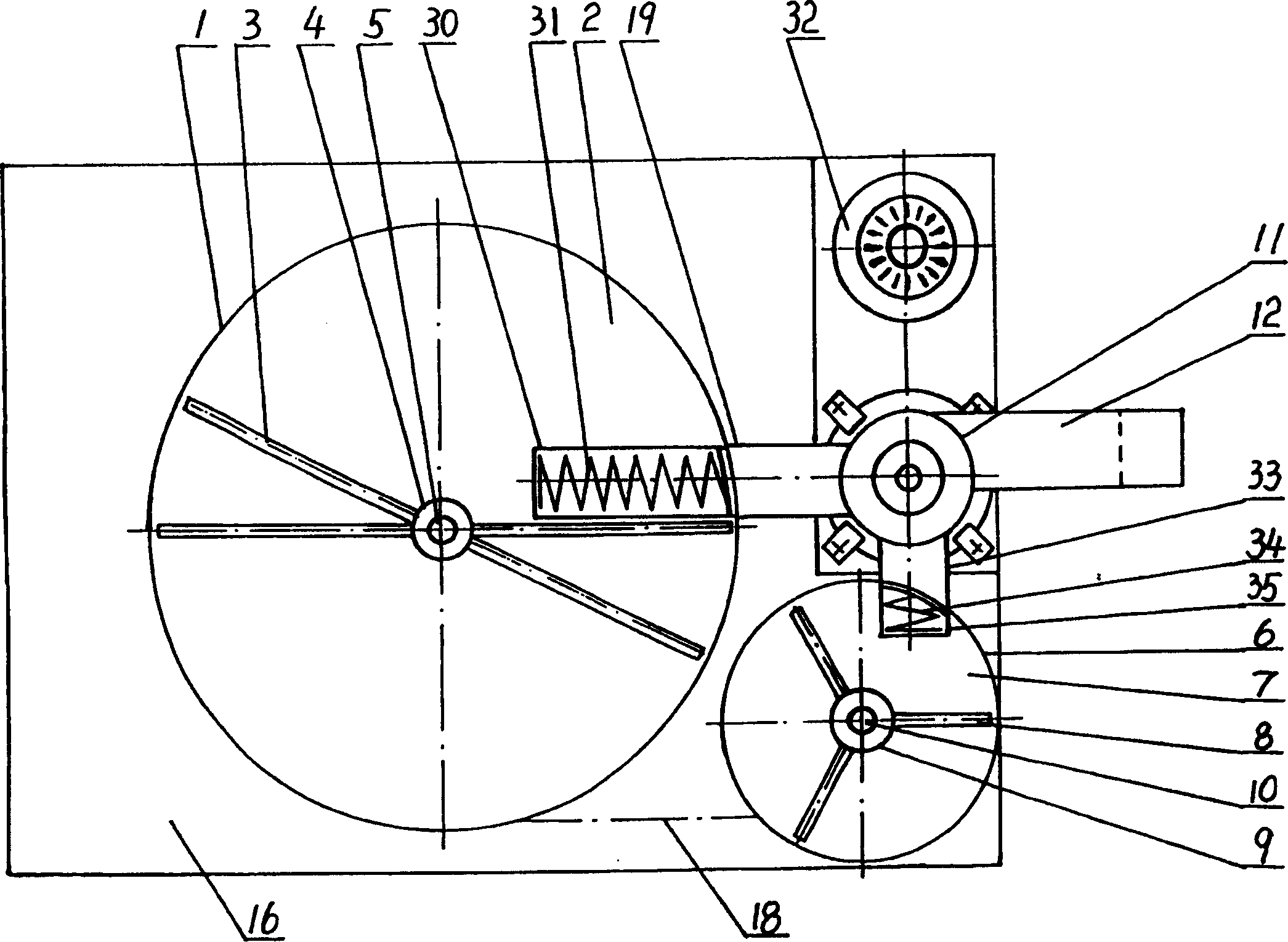

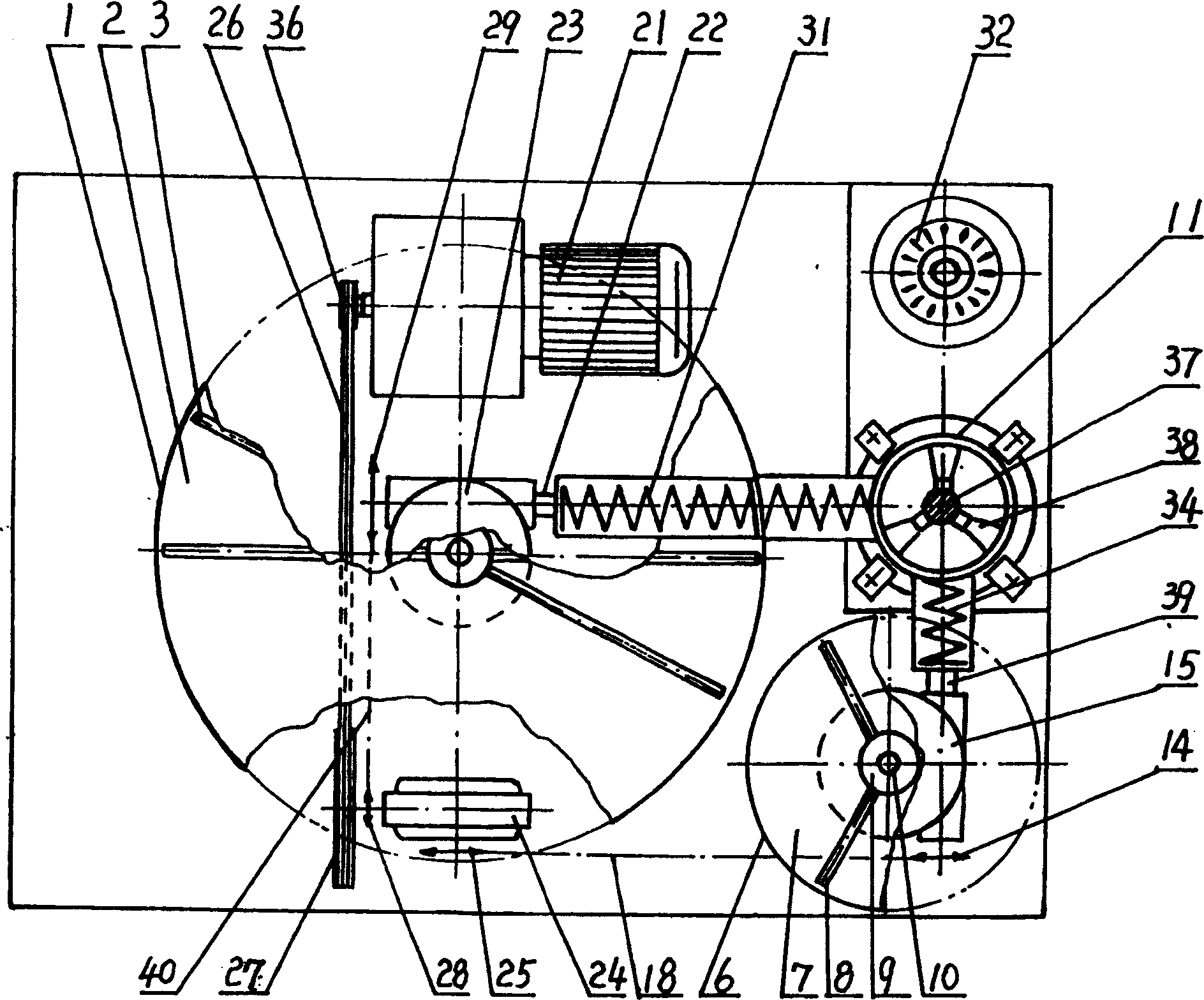

[0015] Such as Figure 1 ~ Figure 4 As shown, the automatic dough mixer includes machine base, vertical dough mixer, main material box, feeding mechanism and transmission system, vertical dough mixer 11, main material box 1, intermediate worm gear reducer 24, vertical dough mixer Machine drive motor 32 and feeding mechanism transmission system drive speed-regulating motor 21 are all fixedly installed on the support 16, for the convenience of installation arrangement equipment, main material box 1 can be fixedly installed on the support 16 by main material box pillar 20, The main material box discharge port 30 on the main material box bottom plate 2 is connected with the main material screw conveyor housing 19, and a set of main material box bottom plate 2 center is fixedly installed below the main material box with a worm gear reducer 23, and the main material box is used for the main material box. The worm gear reducer 23 is driven by the speed regulating motor 21 driven by t...

Embodiment 2

[0017] For Example 1, such as Figure 1 ~ Figure 4 As shown, in order to prevent the shedding phenomenon that may occur in the main material box 1 during work, especially when the bottom plate 2 of the main material box is flat, the powder in the main material box 1 may not be able to pass through the main material box continuously and stably The main material box discharge port 30 on the base plate 2 supplies material to the main material screw conveyor 31, as Figure 1 ~ Figure 3As shown, it is preferable that the worm gear shaft power output end 5 of the worm gear reducer for the main material box passes through the bottom plate 2 of the main material box and is fixedly connected with a main material paddle mounting seat 4, and the main material paddle mounting seat 4 Main material shifting material paddle 3 is fixedly installed on it. With the operation of the worm gear reducer 23 for the main material box, the power output end 5 of the worm gear shaft of the worm gear re...

Embodiment 3

[0019] For embodiment one or embodiment two, in the noodle mixing process, it is often necessary to add some auxiliary materials in proportion to the main ingredients evenly, such as dry noodle powder, etc., especially when producing some special nutritional dried noodles, It is necessary to add a certain proportion of auxiliary materials, such as Figure 1 ~ Figure 4 As shown, preferably on the support 16 is also fixedly installed with an auxiliary material box 6, for the convenience of installation arrangement equipment, the auxiliary material box 6 can be fixedly installed on the machine base 16 by the auxiliary material box pillar 13, the auxiliary material box The auxiliary material box outlet 35 on the base plate 7 is connected with the auxiliary material screw conveyor housing 33, and a set of auxiliary material box worm gear reducer 15 and auxiliary material screw conveyor 34 are fixedly installed under the center of the auxiliary material box bottom plate 7. The power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com