Forging process of Artistic door and window

A manufacturing method and technology for doors and windows, applied in decorative arts, manufacturing tools, fixed grilles, etc., can solve the problems of difficult manufacturing, difficult construction, labor-intensive and other problems, and achieve the effect of convenient handling or processing and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

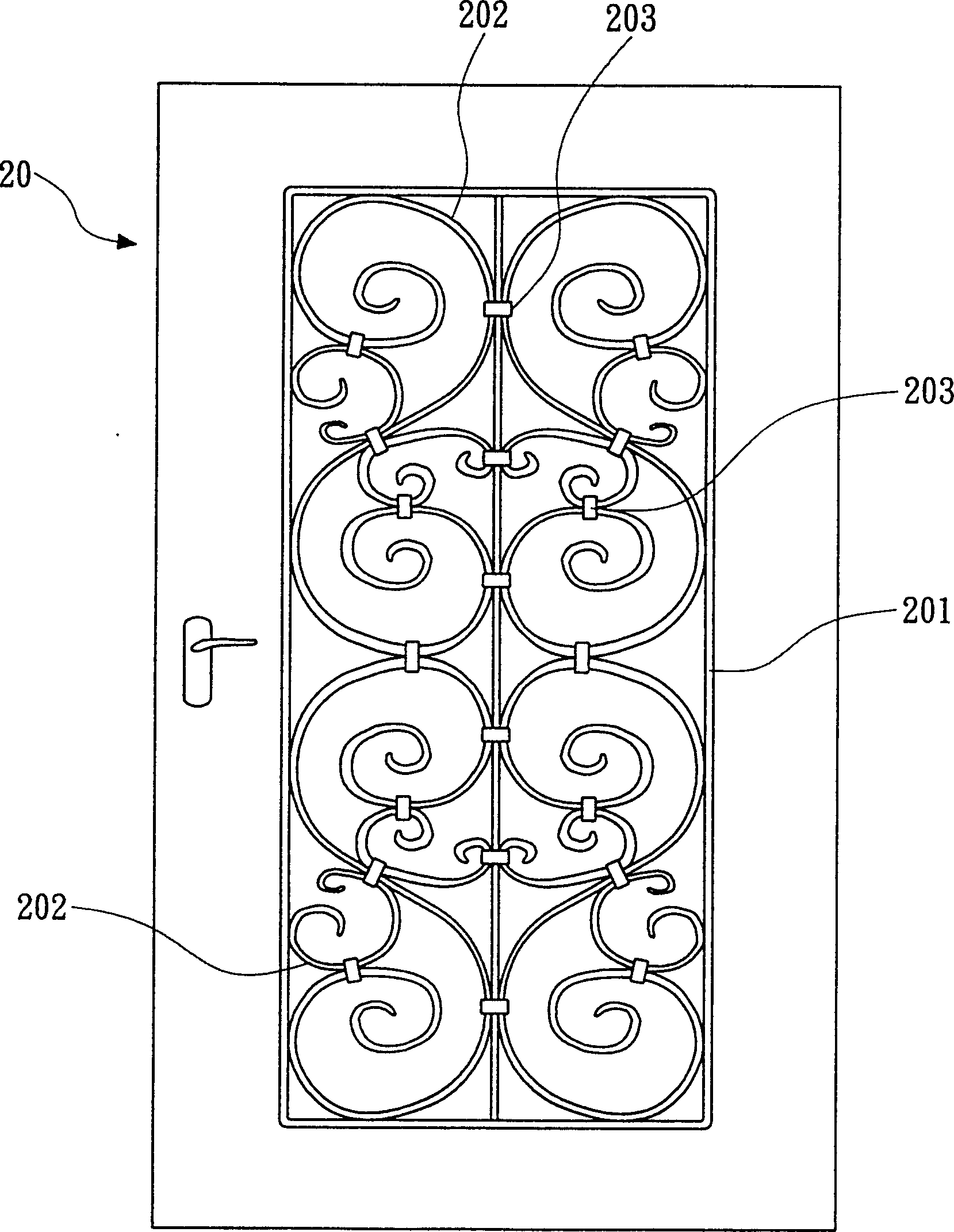

[0029] A kind of manufacturing method of forging type art door and window of the present invention, as Figure 5 As shown, the steps are as follows:

[0030] (1) Using aluminum materials to form the required aluminum components by means of aluminum extrusion or punching;

[0031] (2) Cold forging the aluminum components after aluminum extrusion or stamping to form forged decorative parts required for the facade of artistic doors and windows;

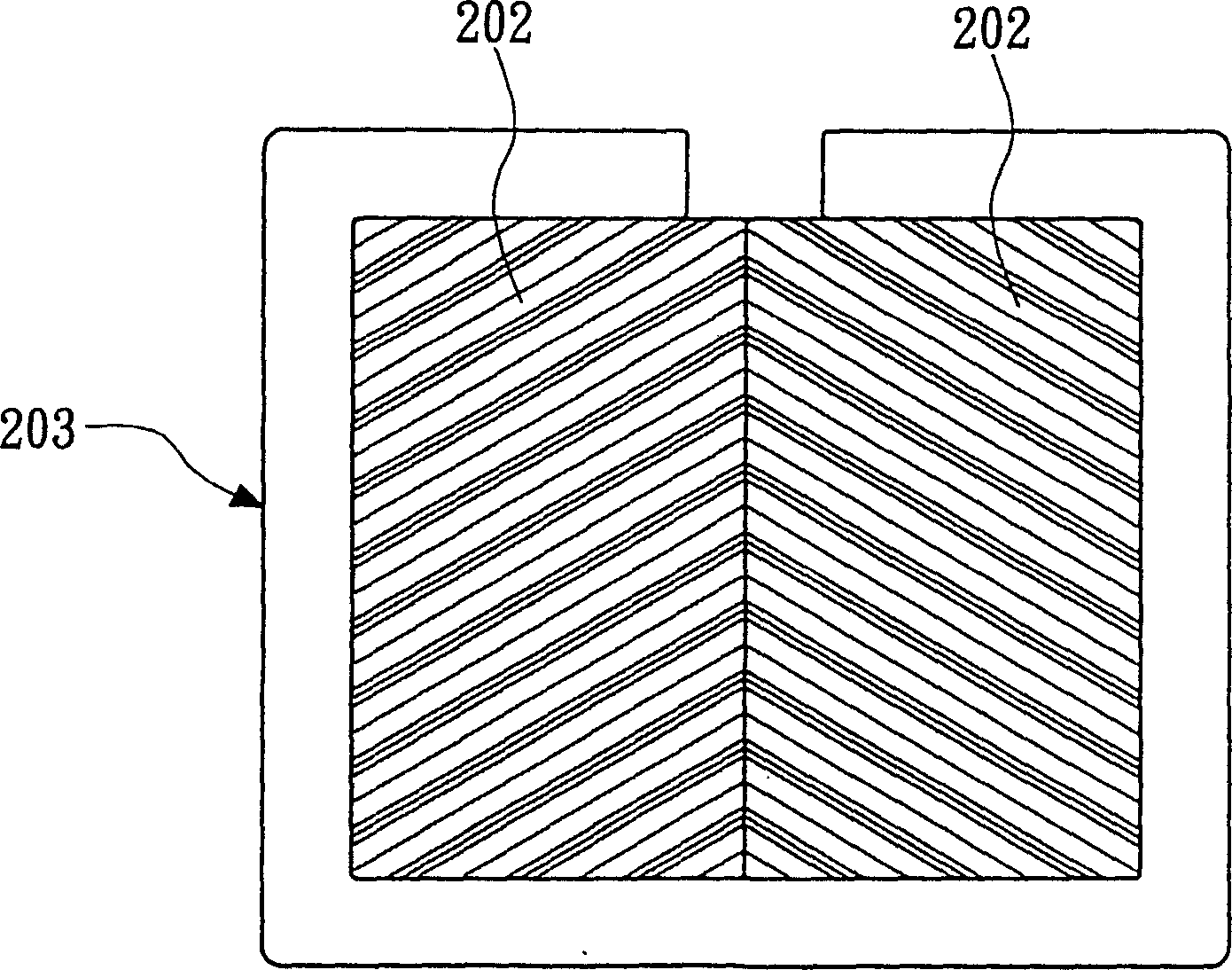

[0032] (3) According to the patterns and styles required on the facade of the entire forged art door and window, a plurality of forged decorative parts are patterned and combined and welded into a whole body;

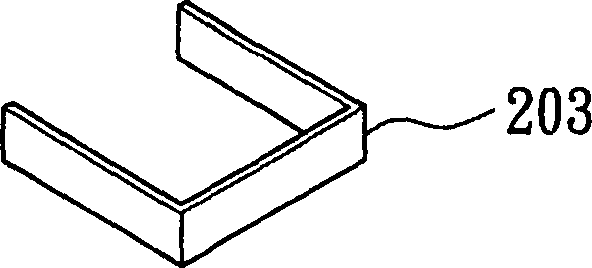

[0033] (4) On the welding points of the joints of these forged decorative parts, fastening decorative parts made of aluminum extruded profiles are used for simple fastening to completely cover the welding points;

[0034] (5) Anodizing the forged decorative parts on the artistic doors and windows, so that the assembly and proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com