Coiling controlling method

A control method and winding shaft technology, applied in the direction of winding strips, control systems, shearing machine control devices, etc., to achieve the effect of reducing costs and reducing the size of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

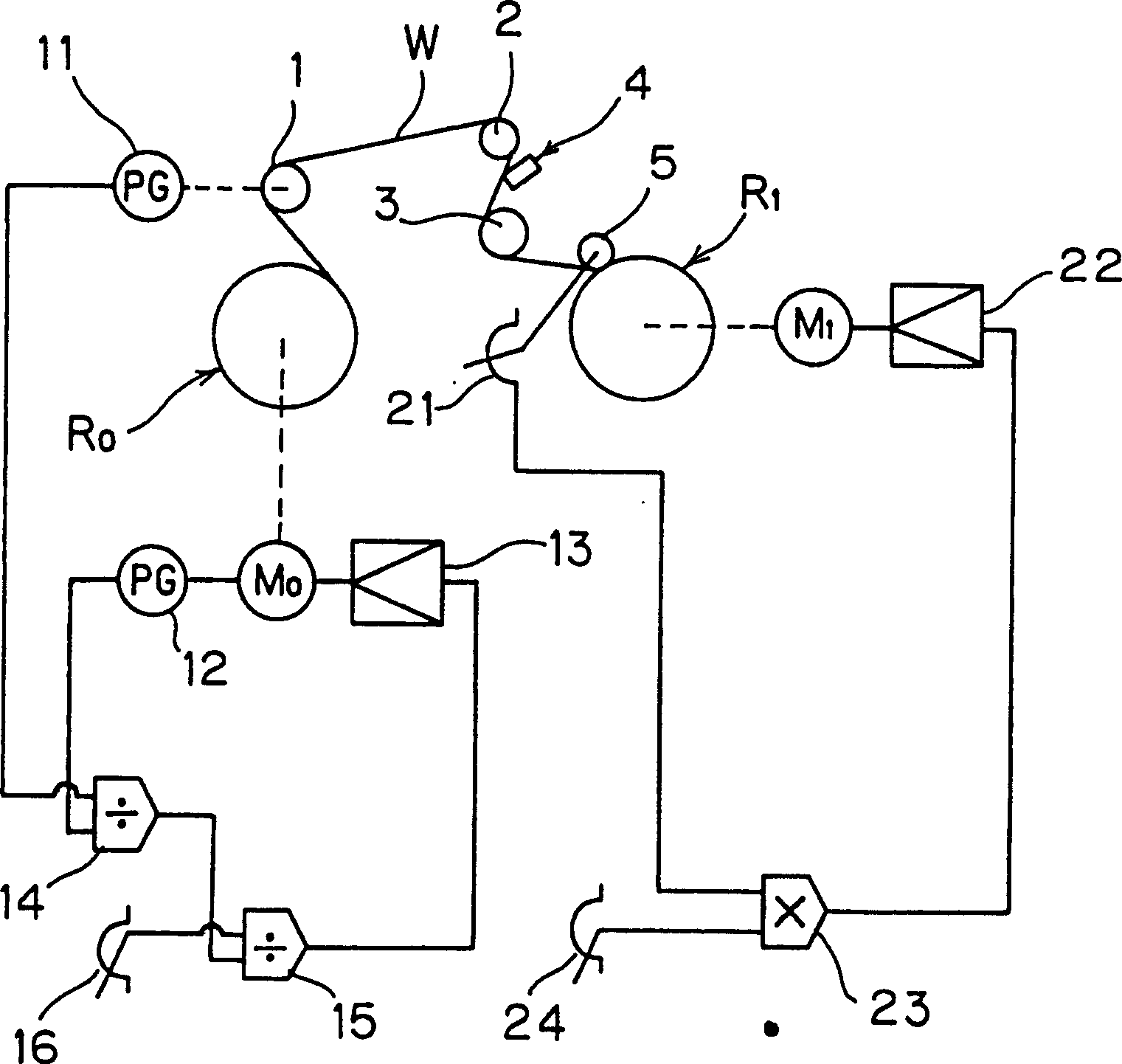

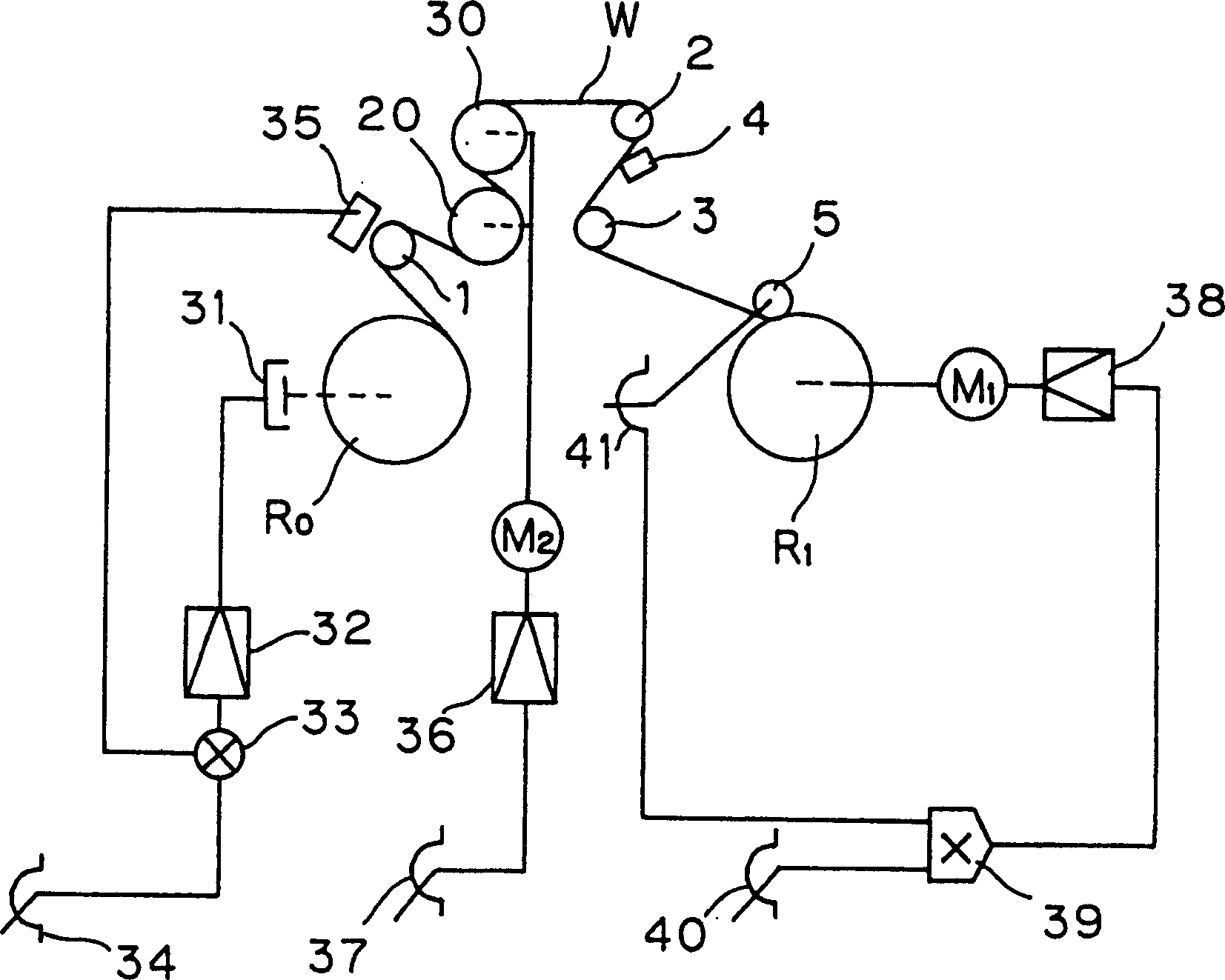

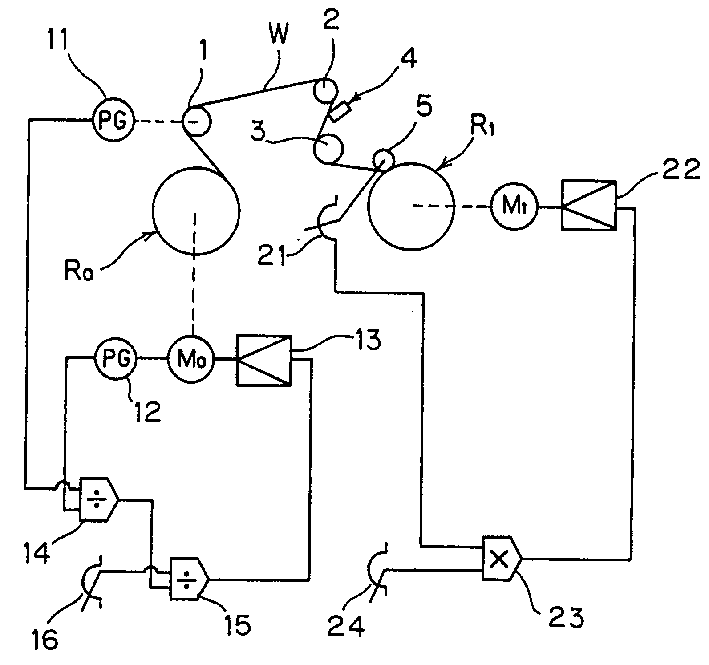

[0016] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings.

[0017] figure 1 Shows the winding control of a representative slitting shear as an outline of the drive system for winding control of the present invention. In the figure, Ro is an unwinding roller, and R 1 In order to wind the rollers, the wide metal thin strip W is drawn out from the unwinding roller Ro installed on the winding shaft through the lead-out roller 1, and is cut into multiple pieces in the length direction with the slitting scissors blade 4 between the guide rollers 2, 3 A narrow metal thin strip, the cut narrow metal thin strip is alternately separated up and down or front and back, and the roller 5 is brought into contact with the respective up and down or front and rear winding shafts to serve as the winding roller R 1 Winding is almost the same as the conventional slitting shear device.

[0018] However, the driving system of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com