Electric motor rotor and its producing method

A technology for electric motors and rotors, applied in the field of producing said rotors, can solve problems such as inconsistencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

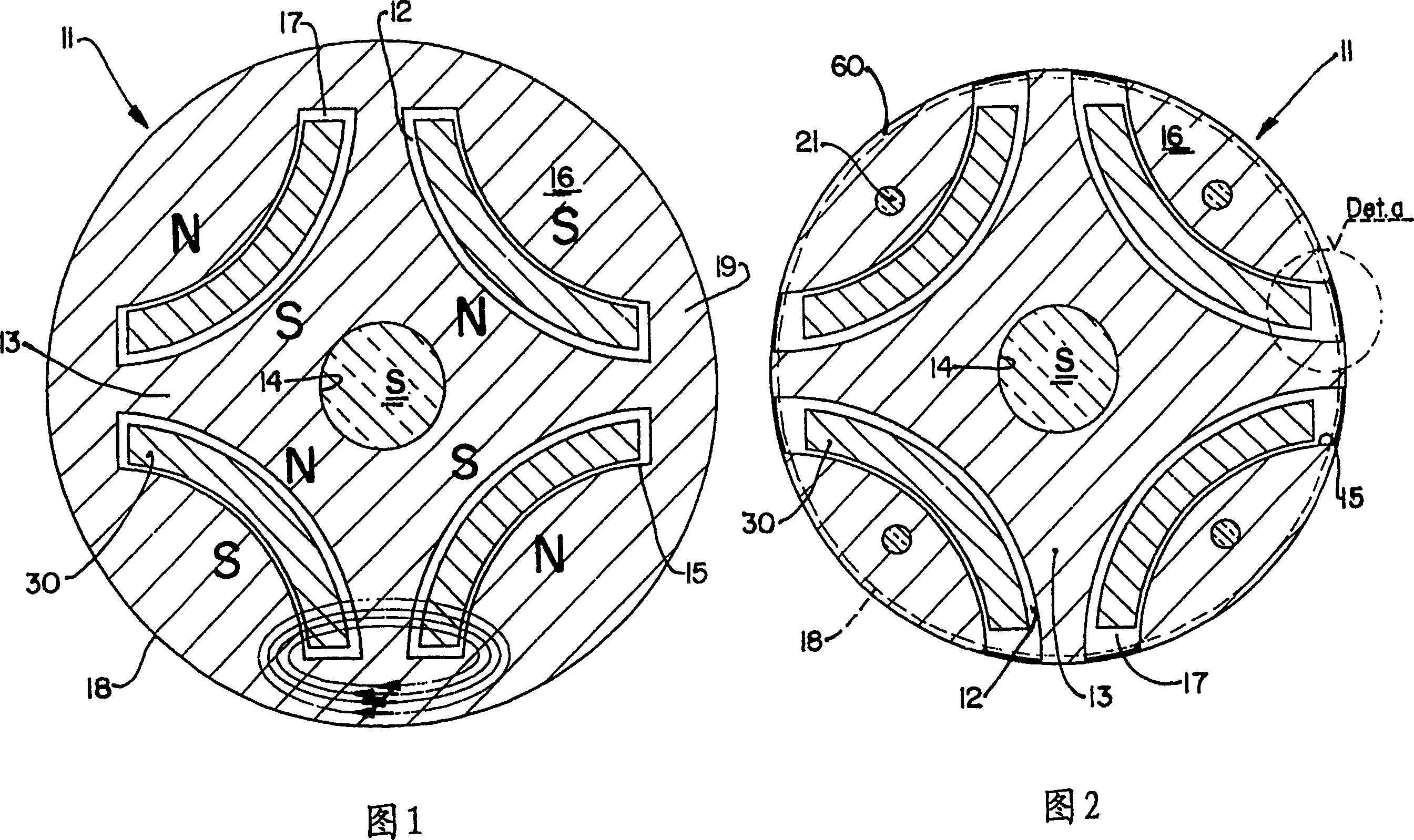

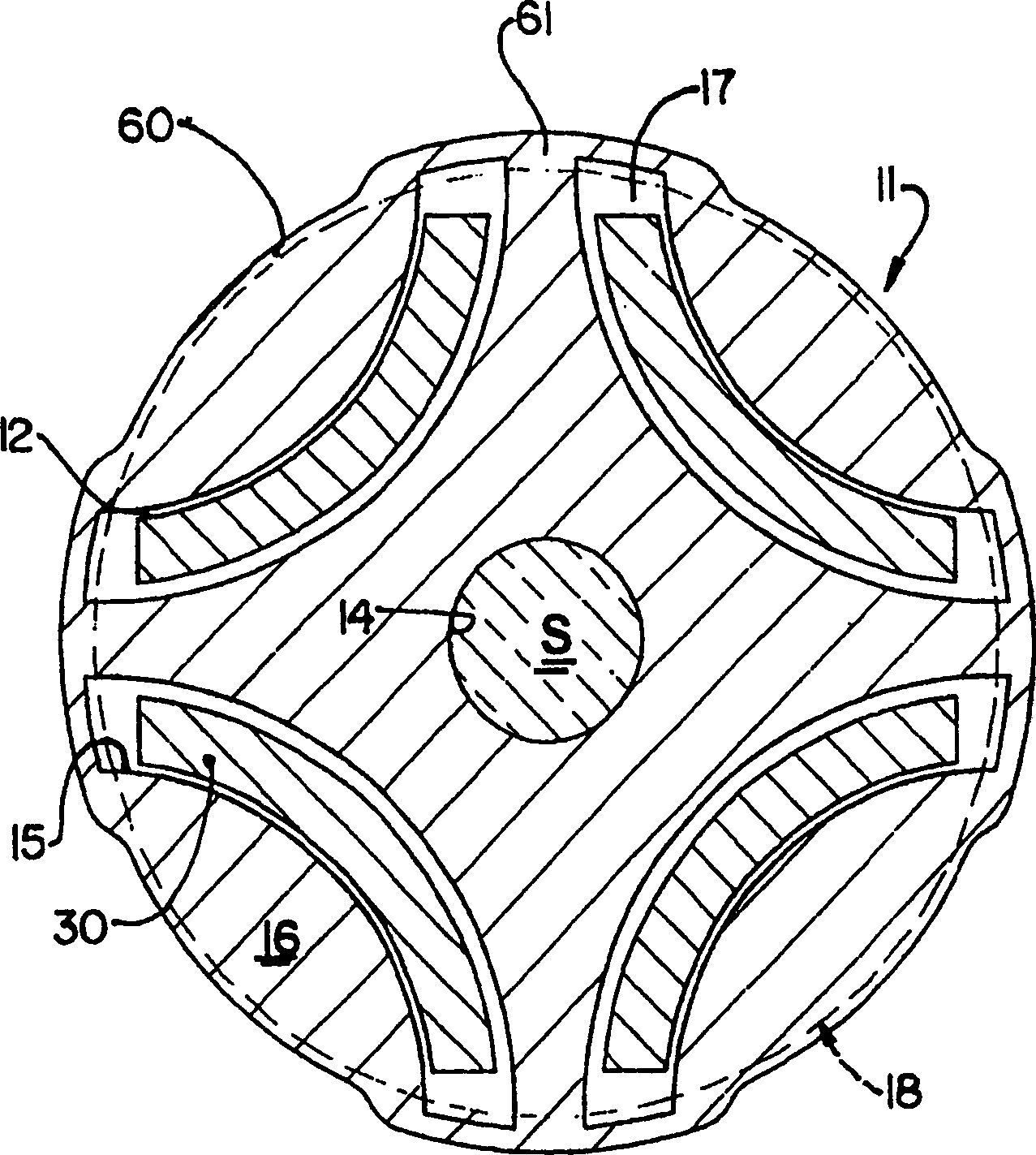

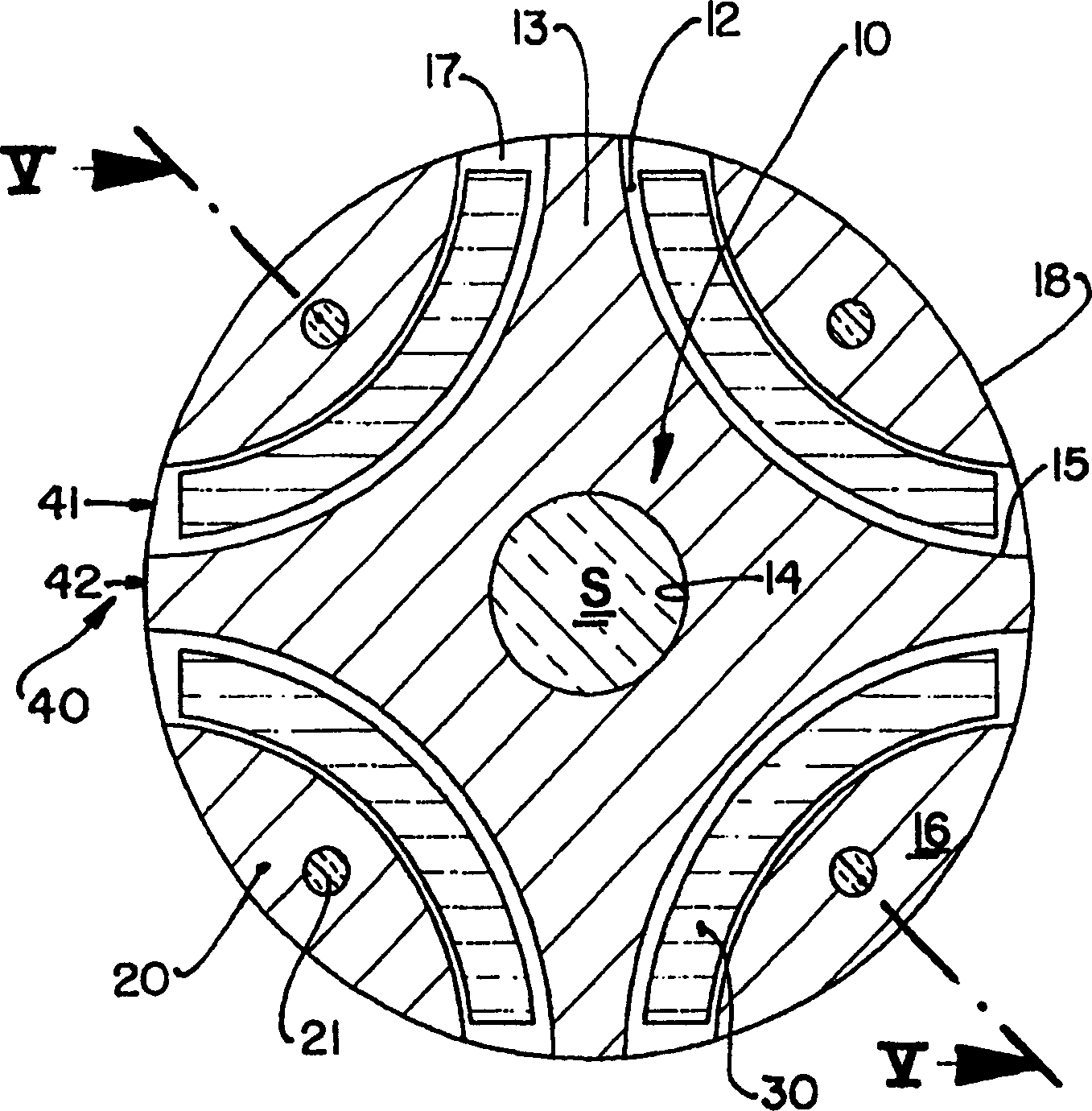

[0019] According to the drawings, the motor rotor of the present invention comprises: a core 10 defined by a plurality of metal laminations 11 of magnetic material such as steel, having a defined electrical conductivity and a defined magnetic permeability, and mutually concentric and overlapping, forming the stack of laminations to be fixed around the extension of the motor shaft S; and the polar peripheral portion 20, fixed around the core 10. Between each said polar peripheral portion 20 and the core 10 is defined an axial housing 12 which occupies the entire longitudinal extension of the rotor and in which a corresponding magnet element 30 is held, said magnet generally having In the form of longitudinal plates, they are for example curved (or rectangular) and arranged according to the same circumferential alignment and spaced from each other.

[0020] According to the prior art, each metal lamination 11 has a central portion 13 provided with: a central opening 14 for mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com