Preparation of magnesium hexasilicate

A magnesium hexasilicate and sodium silicate solution technology, which is applied in the direction of magnesium silicate, silicate, and separation methods, can solve the problems of short double decomposition process flow, long production process flow, and low product strength, and achieve production The effect of simple process, stable product quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

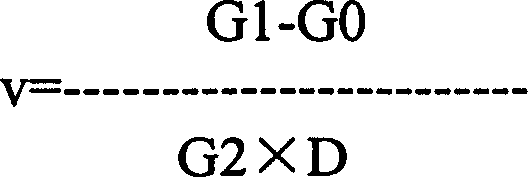

Method used

Image

Examples

Embodiment 1

[0016] 874g of magnesium sulfate heptahydrate is formulated into a solution with a magnesium oxide concentration of 4.0%, then 2000g of water glass with a modulus of 3.5 is added, the pH value is adjusted to 8.9, and after the temperature rise and heat preservation reaction, 10g of polyacrylamide with a molecular weight of 7.5 million is added As a flocculant, it is then centrifuged to obtain wet magnesium hexasilicate, and then sprayed and granulated to obtain white magnesium hexasilicate particles.

Embodiment 2

[0018] It is 3.0% solution that 874g magnesium sulfate heptahydrate is mixed with magnesium oxide concentration, then add 2200 g modulus and be 3.0 water glass, adjust pH value to 9.1, after carrying out heating and heat insulation reaction, add 8g molecular weight respectively 7,500,000 and 1,500 Wan's polyacrylamide mixture is used as a flocculant, centrifuged to obtain wet magnesium hexasilicate, and then sprayed and granulated to obtain white magnesium hexasilicate particles.

Embodiment 3

[0020] 874g of magnesium sulfate heptahydrate is prepared into a solution with a magnesium oxide concentration of 4.0%, and then 2000 g of water glass with a modulus of 3.5 is added to adjust the pH value to 9.1. Each 5g of polyacrylamide was used as a flocculant, and then centrifuged to obtain wet magnesium hexasilicate, then 0.8g of polyethylene glycol was added as a strength improver, and white magnesium hexasilicate particles were obtained through spray granulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com