Method for preparing high-quality tar by pyrolyzing plastic wastes

A waste, high-quality technology, used in the preparation of liquid hydrocarbon mixtures, products, coke ovens, etc., can solve the problems of cluttered products, low content of gasoline and diesel fractions, rough production processes, etc., to improve the octane number. , The effect of low operating cost and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] In the present invention, wt% means weight%.

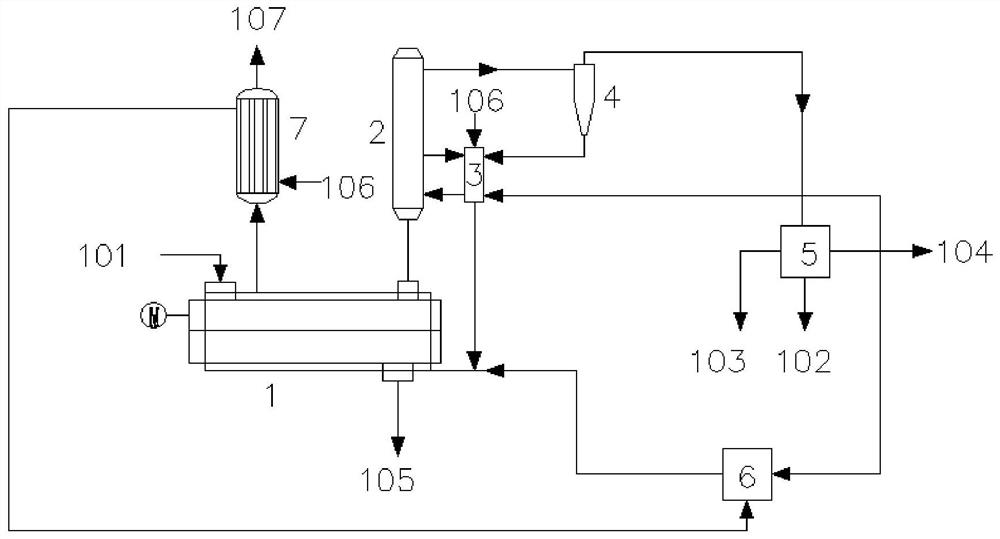

[0058] Plastic waste rich in polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), etc. is sent to the pyrolysis reactor, and the temperature of the pyrolysis reaction is controlled at 500°C , the system maintains a slightly positive pressure operation (1-5KPa), and the generated high-temperature pyrolysis steam is sent to the catalytic reactor, and the catalytic reactor adopts a fluidized bed reactor. The catalytic cracking temperature is controlled at 450°C, the catalytic reactor is heated and kept warm by electric heating, and the catalyst is Al 2 o 3 -SiO 2 solid catalyst. After 3 days of operation, the catalyst is regenerated in the catalyst regenerator, the regeneration method is air combustion, and the temperature is 900°C. The high-temperature pyrolysis steam is exported from the outlet of the catalytic reactor into the condensation separation device, and light oil, pyrolysis water a...

Embodiment 2

[0068] Plastic wastes rich in polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), etc. are sent to the pyrolysis reactor, and the temperature of the pyrolysis reaction is controlled at 500°C , the system maintains a slightly positive pressure operation (1-5KPa), and the generated high-temperature pyrolysis steam is sent to the catalytic reactor, and the catalytic reactor adopts a fluidized bed reactor. The catalytic cracking temperature is controlled at 450°C, the catalytic reactor is heated and kept warm by electric heating, and the catalyst is Al 2 o 3 -SiO 2solid catalyst. After running for 3 days, it will be regenerated in the catalyst regenerator. The regeneration method is air combustion and the temperature is 900°C. The high-temperature pyrolysis steam is exported from the outlet of the catalytic reactor into the condensation separation device, and light oil, pyrolysis water and pyrolysis gas are separated. Part of the pyrolysis gas is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com