Cam device

A technology of cam device and cam groove, applied in the direction of cam, transmission device, cam follower, etc., to achieve the effects of improved durability, reduced sliding wear, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be more clearly understood by describing the following preferred embodiments with reference to the accompanying drawings. However, the embodiments and drawings are only for illustration and description. The scope of the invention is defined by the claims. In the drawings, the same reference numerals in different drawings indicate the same or corresponding parts.

[0024] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

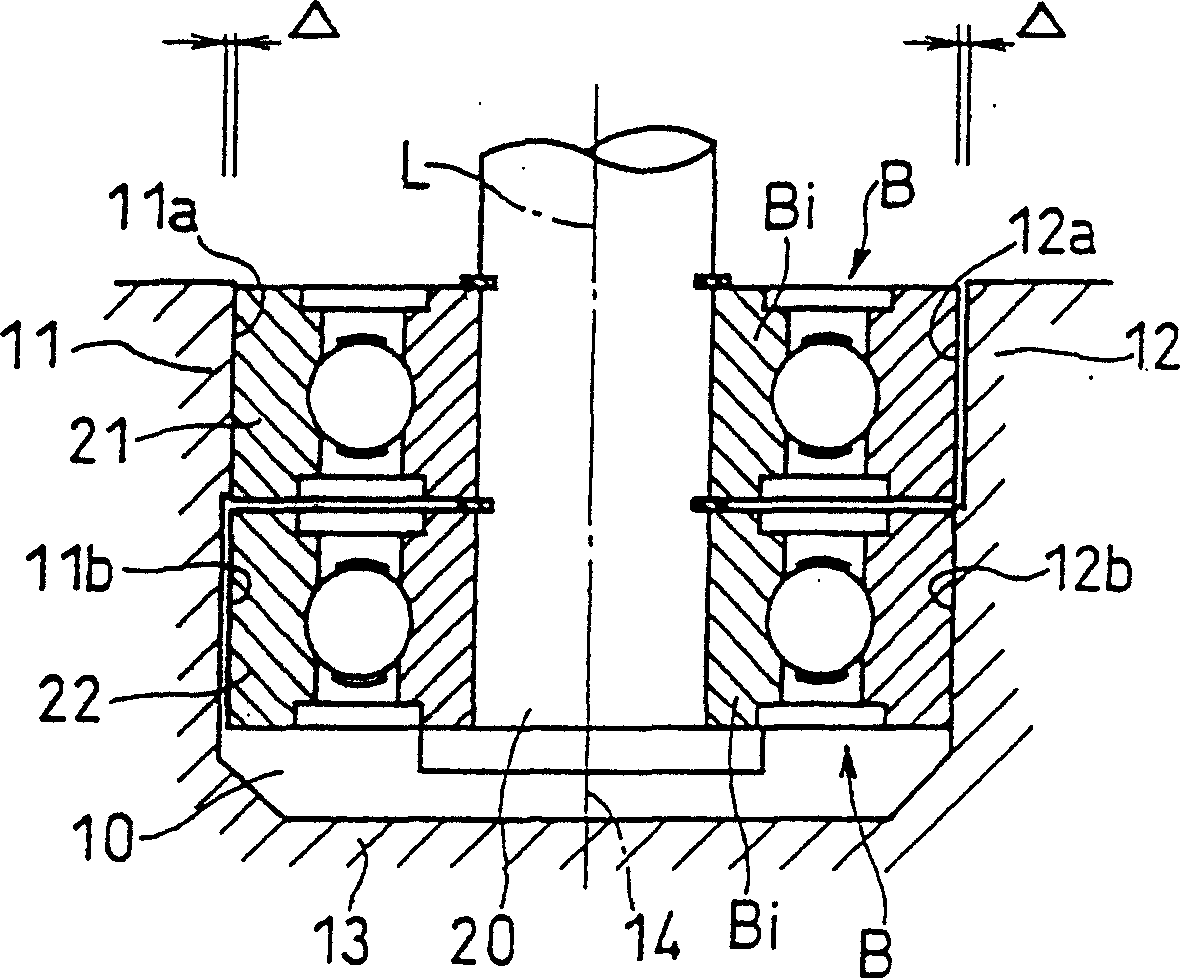

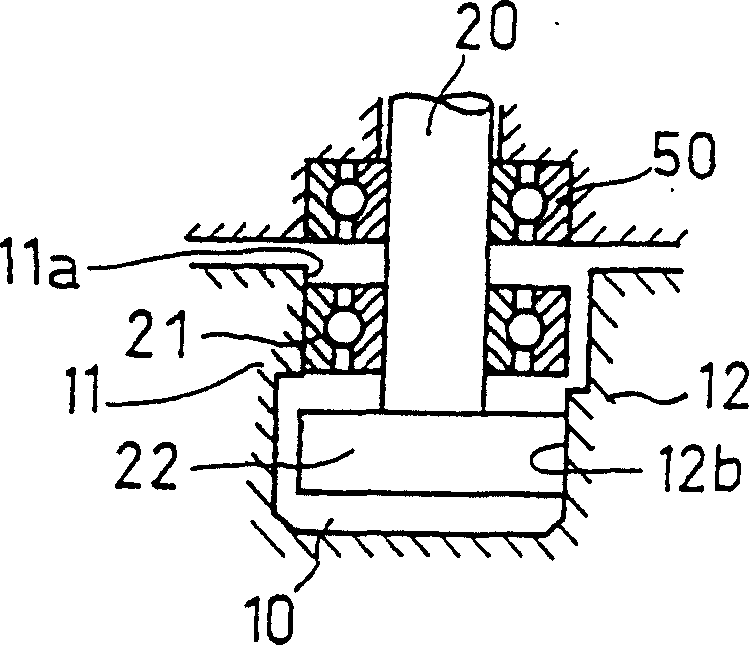

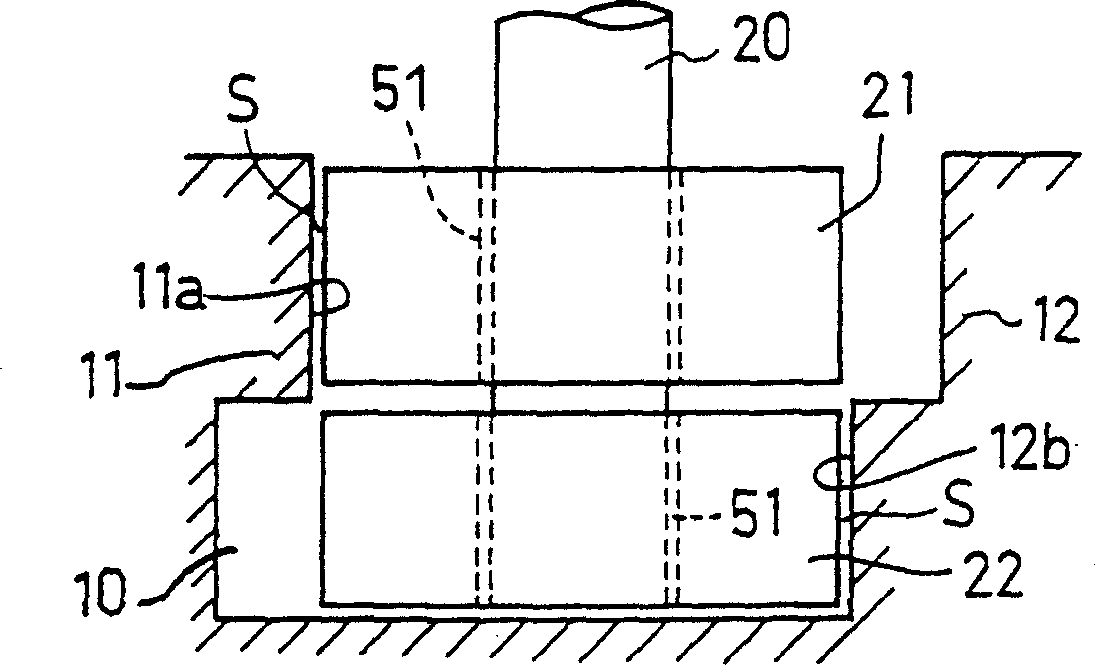

[0025] In the cam device of this embodiment, if figure 2 As shown in the cylindrical cam 1 shown in FIG. 1 , along an annular cam groove 10 formed on a curved surface, the outer peripheral surfaces of the first and second cam followers 21 and 22 perform predetermined movements while rotating.

[0026] On the outer periphery of the front end portion of the shaft 20 shown in FIG. 1( a), first and second cam followers 21 and 22 are respectively freely rotatable, and are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com