Fried instant noodles and its making method

A manufacturing method and instant noodle technology, applied in food preparation, application, food science, etc., can solve problems such as inability to achieve viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

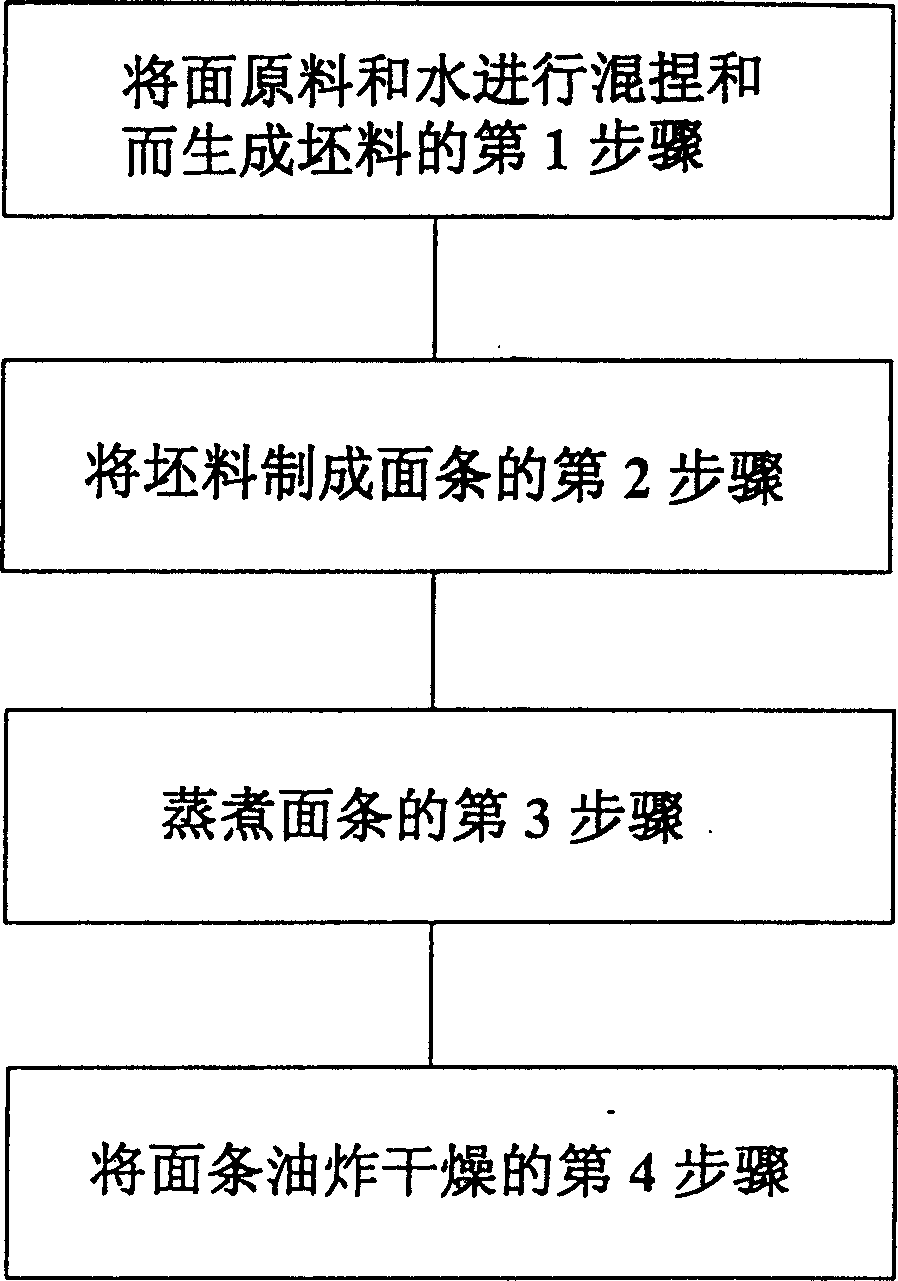

Method used

Image

Examples

Embodiment 1

[0035] Using 330ml of added water, knead a dough made of 800g of wheat flour, 170g of potato starch, 30g of alpha-acetated tapioca starch (DS=0.07), 3g of alkaline water, 10g of salt, and 5g of casein, whey, and milk protein to make noodles. Then, cut out with a knife blade: 18 square, surface thickness: 1.30mm, and 0.5kg / cm 3 After continuous steaming for 3 minutes, the steamed noodles cut into a surface weight of 90 g were filled in the drying template. After that, it was passed through an oil layer adjusted to a temperature of 145°C for 2 minutes to obtain a fried instant noodle with a final moisture content of 3%.

Embodiment 2

[0037] Use 330ml of water to mix 800g wheat flour, 170g potato starch, 30g α-acetate potato starch (DS=0.03), 3g lye, 10g salt, 5g egg protein, and knead the dough. After making the dough, use the knife edge: 18 Square, surface thickness: 1.30mm to cut out, 0.5kg / cm 3 After continuous steaming for 3 minutes, the steamed noodles cut into a surface weight of 90 g were filled in the drying template. After that, it was passed through an oil layer adjusted to a temperature of 145°C for 2 minutes to obtain a fried instant noodle with a final moisture content of 3%.

Embodiment 3

[0039] Mix and knead a dough made of 800g wheat flour, 170g potato starch, 30g α-alkaline potato starch (raw), 3g alkaline water, 10g salt, and 5g casein whey milk protein with 330ml of added water. After making noodles, Cut out with blade: 18 square, surface thickness: 1.30mm, 0.5kg / cm 3 After continuous steaming for 3 minutes, the steamed noodles cut into a surface weight of 90 g were filled in the drying template. After that, it was passed through an oil layer adjusted to a temperature of 145°C for 2 minutes to obtain a fried instant noodle with a final moisture content of 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com