Radiation testing system and method

A radiation detection and to-be-detected technology, applied in the field of radiation detection systems, can solve problems such as high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The radiation detection system of the embodiment of the present invention and its usage will be described in detail below with reference to the accompanying drawings.

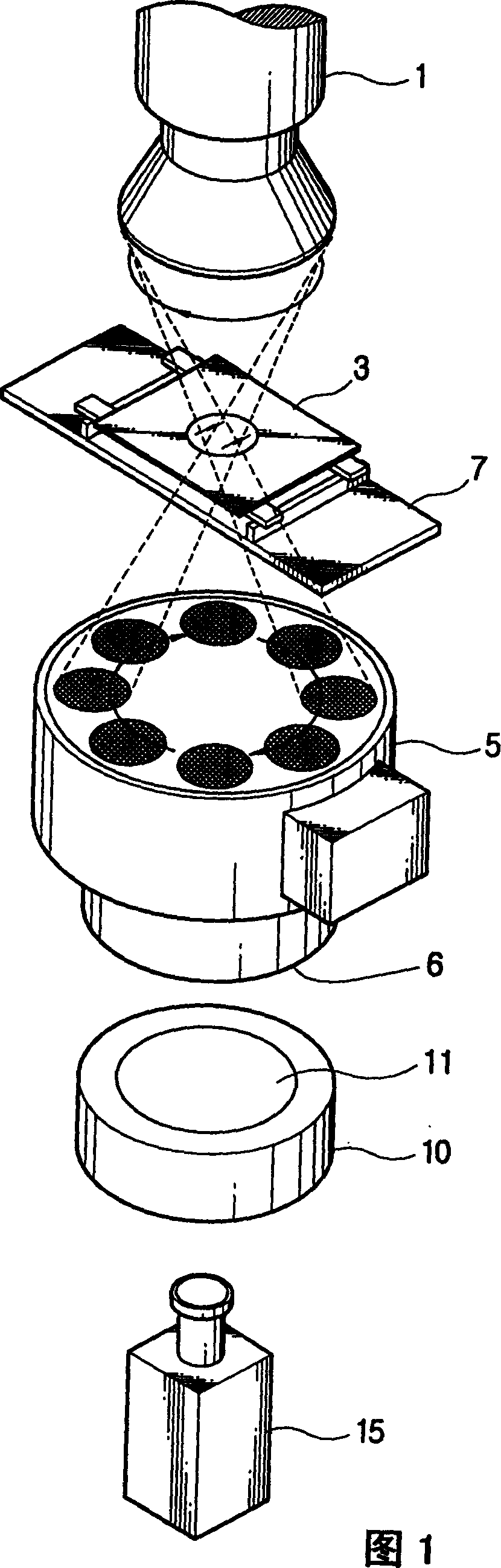

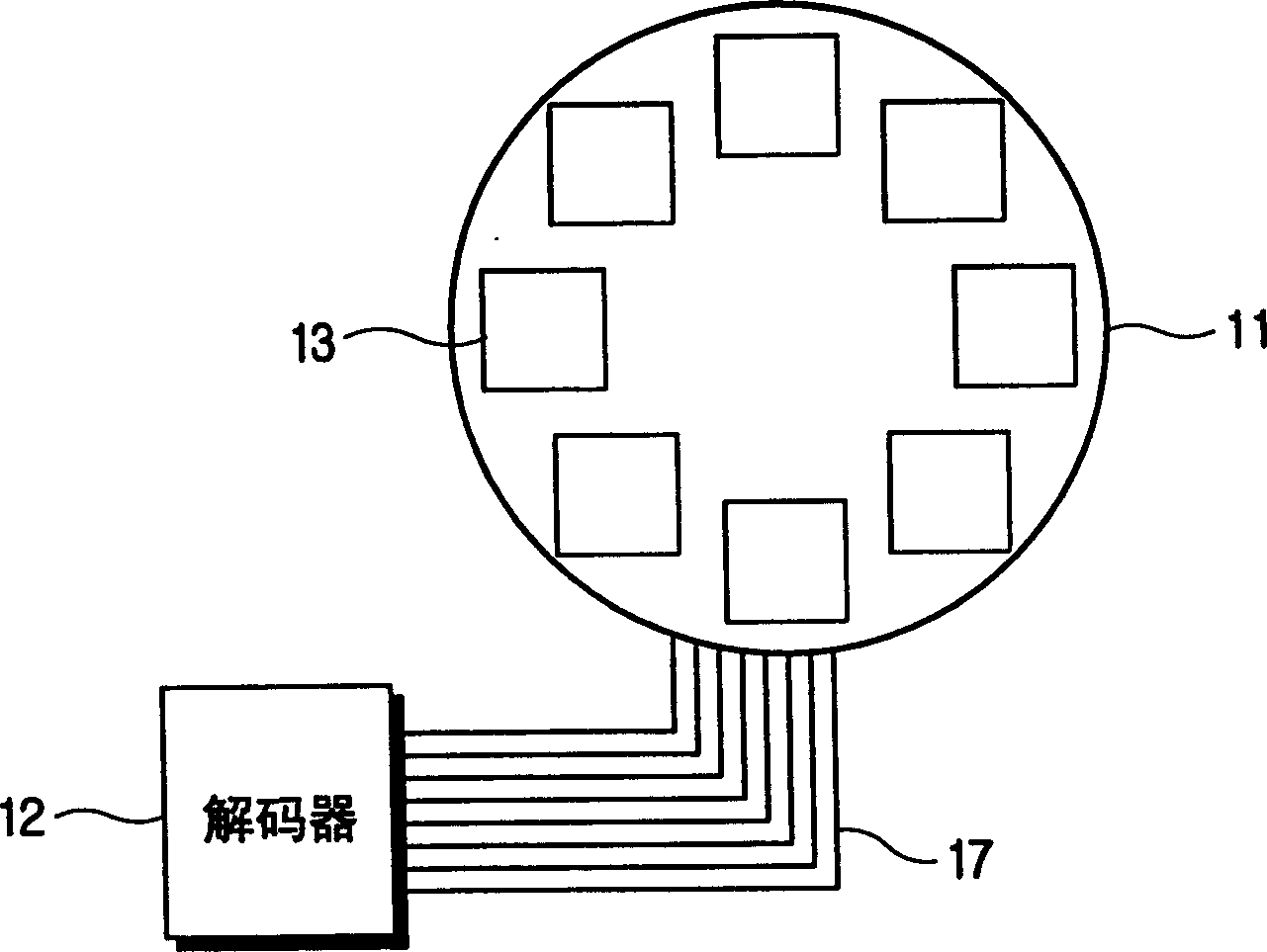

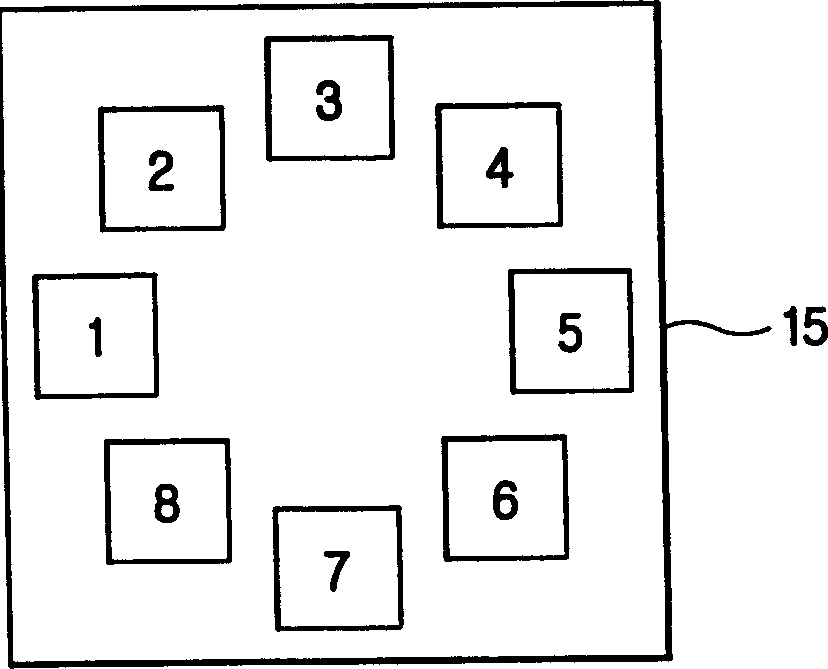

[0035] Fig. 1 schematically represents a perspective view of a radiation detection system of an embodiment of the present invention; figure 2 A top view showing the polarizing filter of the electronic gate shown in Fig. 1. As described therein, the radiation detection system includes: an X-Y table 7 on which an object 3 intended to be detected by NDT is placed; an electron tube 1 for controlling X-rays that produces X-rays to the detection area of the object 3; an image intensifier 5, which is used to form a visual image by the X-rays transmitted through the object 3, it has a visual image part 6, said visual image is projected on it; electronic gate 10, which has a visual image Sending part 11, is used for transmitting the visual image from image intensifier 5 in sequence; And a CCD camera 15, is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com