Actuating device

A technology for operating devices and hoses, which is applied in the direction of fluid pressure actuating devices, hoses, pipes, etc., and can solve problems such as bursting, restrictions on the realization of pipeline structures, and insufficient pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

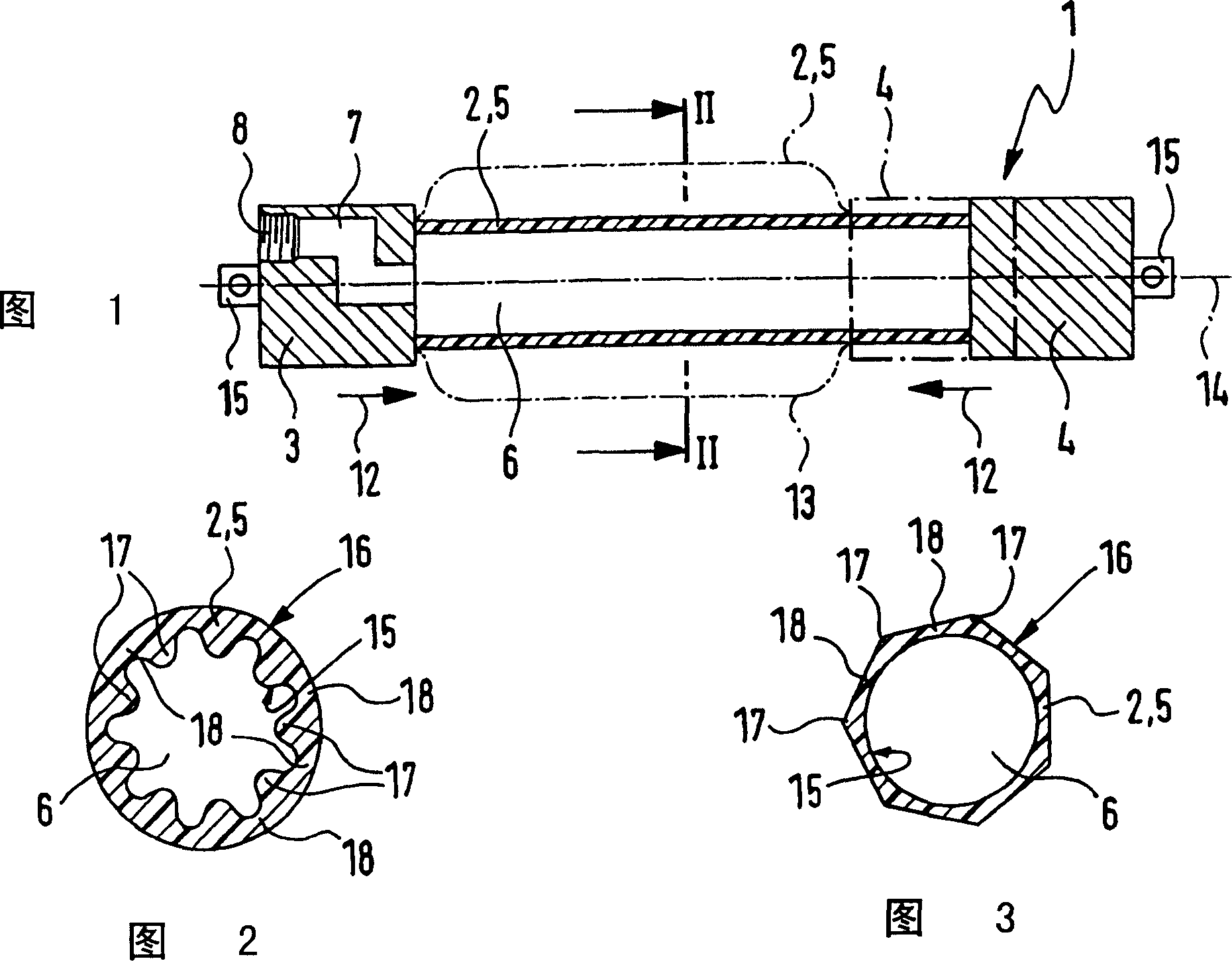

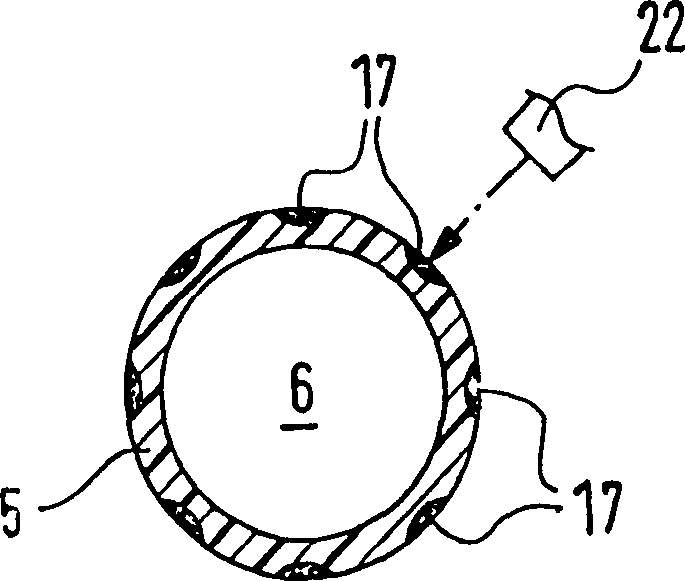

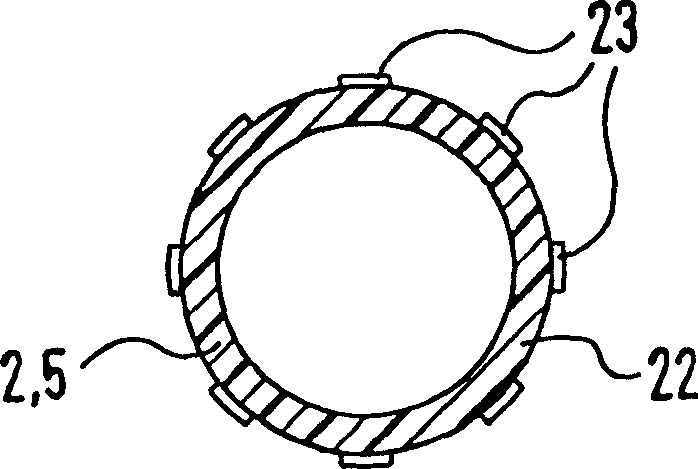

[0016] The operating device 1 shown in a greatly simplified manner in FIG. 1 comprises two heads 3 , 4 arranged at a distance from one another, which are fixedly connected to one another via a hollow body having a straight line and referred to as shrink tube 2 . The shrink hose 2 consists of an elastically deformable, fluid-impermeable hose body 5, which defines an inner cavity 6 passing between the two heads 3, 4, and is defined by its two axial end portions The sections are respectively fixed sealingly on one of the two heads 3 , 4 . Fastening can take place, for example, in the context of a clamp connection, as described in EP 0161750 B1 as an example. However, other fastening methods are also possible.

[0017] At least one fluid passage 7 leads into the inner cavity 6 surrounded by the hose body 5 and the two heads 3, 4, the fluid passage passes through a head 3, and its outer end is equipped with a connecting device 8, through which The connection device can connect fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com