A biological hard tissue replacement and repair material and its preparation method

A technology for repairing materials and hard tissues, applied in medical science, prosthesis, etc., can solve the problems of unstable mechanical and chemical properties of materials, difficulty in uniform dispersion of nanoparticles, uneven distribution of hydroxyapatite, etc., and achieve good interface bonding , easy to control, overcome the effect of interface mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

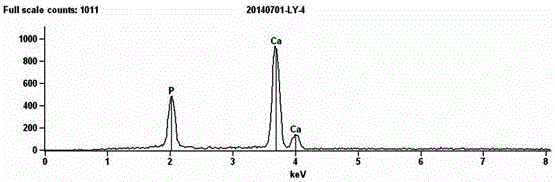

[0046] Accurately measure 31.8g of methyl methacrylate (MMA) monomer in a beaker, then weigh 0.265g of lecithin (the mass ratio of lecithin and HA is 1:6) and add it to the methyl methacrylate monomer, Stir evenly with a glass rod, add to a four-necked flask equipped with an electric stirring rod, and keep stirring evenly and rapidly. Grind Ca(NO 3 ) 2 • 4H 2 O and (NH 4 ) 2 HPO 4 Fine powder, and accurately weigh 2.36gCa(NO 3 ) 2 • 4H 2 O and 0.79g (NH 4 ) 2 HPO 4 (Where Ca / P molar ratio n(Ca) / n(P)=1.67), slowly add into the four-necked flask. Accurately weigh 0.095g of benzoyl peroxide initiator and an appropriate amount of NaOH into a four-neck flask, keep the pH at 10, heat in a water bath to 70°C, and keep the temperature for 3 hours to make Ca(NO 3 ) 2 • 4H 2 O and (NH 4 ) 2 HPO 4 In the process of in-situ precipitation of hydroxyapatite from the powder, the polymethyl methacrylate prepolymer is obtained by in-situ polymerization at the same time. Heat ...

Embodiment 2

[0053] Accurately measure 31.8g of methyl methacrylate (MMA) monomer in a beaker, then weigh 0.265g of lecithin (the mass ratio of lecithin and HA is 1:6) and add it to the methyl methacrylate monomer, Stir evenly with a glass rod, add to a four-necked flask equipped with an electric stirring rod, and keep stirring evenly and rapidly. Grind Ca(NO 3 ) 2 • 4H 2 O and (NH 4 ) 2 HPO 4 Fine powder, and accurately weigh 2.36gCa(NO3)2•4H2O and 0.79g(NH4)2HPO4 (wherein Ca / P molar ratio n(Ca) / n(P)=1.67), slowly add into the four-necked flask. Accurately weigh 0.095g of benzoyl peroxide initiator and an appropriate amount of NaOH into a four-neck flask, keep the pH at 10, heat in a water bath to 70°C, and keep the temperature for 3 hours to make Ca(NO 3 ) 2 • 4H 2 O and (NH 4 ) 2 HPO 4 In the process of in-situ precipitation of hydroxyapatite by powder reaction, polymethyl methacrylate prepolymer is obtained by in-situ polymerization at the same time. Heat it in a water bath...

Embodiment 1 and Embodiment 2

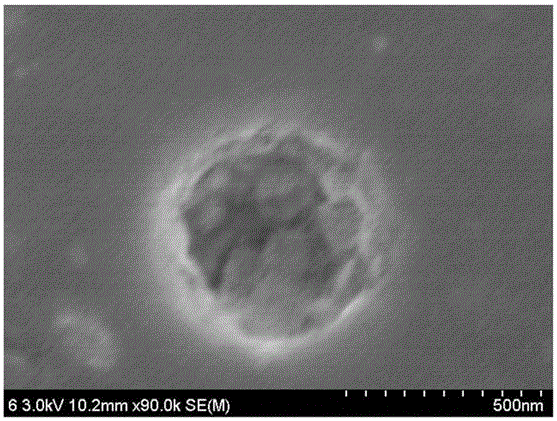

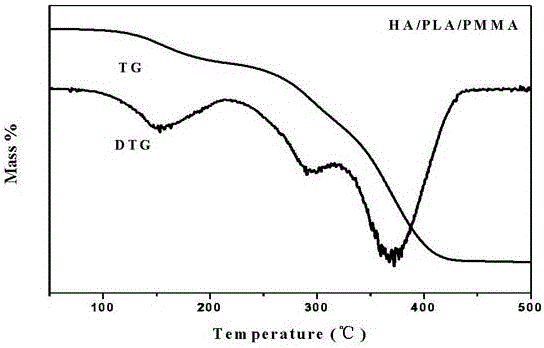

[0061] Combining Example 1 and Example 2, the method of the present invention has prepared a nano-hydroxyapatite-polymethyl methacrylate-polylactic acid ternary composite material, and the synthesis of hydroxyapatite and the polymerization of monomers are in the same phase Among them, the hydroxyapatite particles are uniformly wrapped in the organic polymer matrix to form a microphase separation structure, without obvious phase interface, and have good chemical bonds with the polymer matrix; the particle size of hydroxyapatite is 300-500nm; It has the advantages of uniform material properties, good interface compatibility, and good thermal stability; after heat treatment, the composite material is milky white, smooth and uniform in appearance, without obvious bubbles, and has the advantages of the three materials, and has good biocompatibility properties, low specific density, high strength, and good biodegradability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com