Method for producing red brass pipe

A red brass, manufacturing method technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of small aspect ratio, small size, unsuitability, etc., and achieve uniform and good material properties The effect of uniform support and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

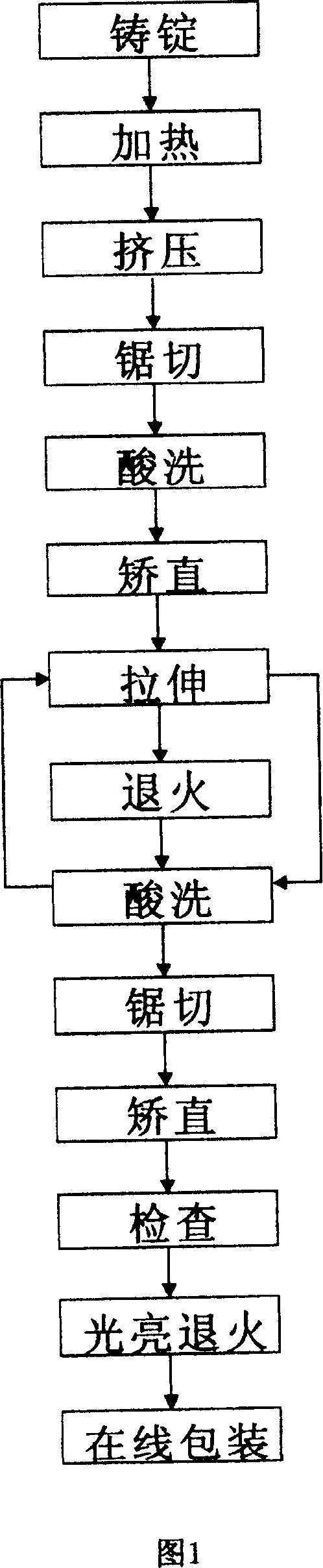

specific Embodiment approach 1

[0025] Produce a red brass tube with φ88.9×5.56 and H58 state.

[0026] Ingot casting: use a melting furnace to cast an ingot.

[0027] Heating: Use a heating furnace for heating, the heating temperature is 860°C, and the heating time is 2.5 hours.

[0028] Extrusion: Use hydraulic press to extrude and preheat the supporting extrusion cylinder, perforated needle, extrusion pad and extrusion die. The preheating temperature of the extrusion cylinder is 450℃ and the preheating time is 2.5 hours; the preheating temperature of the perforation needle, the extrusion pad and the extrusion die is 400℃, the preheating time is 2.5 hours, the extrusion die is φ115mm, and the perforation needle It is φ100mm; the extrusion temperature is 860°C, the extrusion speed is 30mm / min, and the extrusion ratio is 16.28. Extruded into a tube blank of φ115×7.5mm.

[0029] Sawing: Use a circular saw to cut the head and tail.

[0030] Pickling: Pickling the pipe in the pickling tank. The sulfuric acid concen...

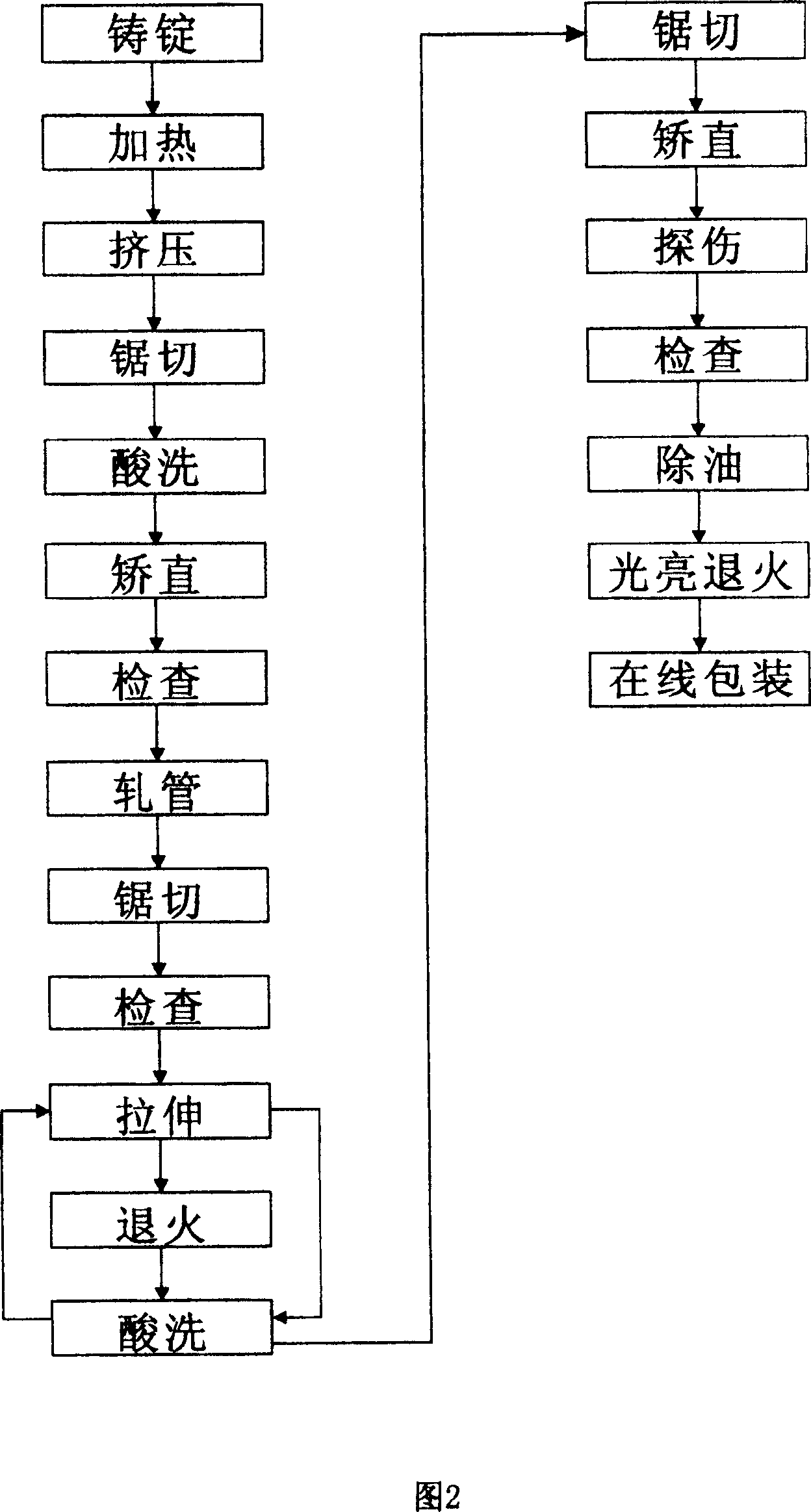

specific Embodiment approach 2

[0039] Produce a red brass tube of φ21.33×2.72mm and O61 state.

[0040] Ingot casting: use a melting furnace to cast an ingot.

[0041] Heating: Use a heating furnace for heating, the heating temperature is 800°C, and the heating time is 1.5 hours.

[0042] Extrusion: Use a hydraulic press to extrude and preheat the matching extrusion cylinder, perforation needle, extrusion pad and extrusion die. The preheating temperature of the extrusion cylinder is 350℃ and the preheating time is 3 hours; the preheating temperature of the perforation needle, the extrusion pad and the extrusion die is 300℃, the preheating time is 3 hours, the extrusion die is φ80mm, and the perforation needle It is φ60mm; the extrusion temperature is 800°C, the extrusion speed is 20mm / min, and the extrusion ratio is 21. It is extruded into a tube blank of φ80×60mm.

[0043] Sawing: Use a circular saw to cut the head and tail.

[0044] Pickling: Pickling the pipe in the pickling tank. The sulfuric acid concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com