Mudding-free type testing coke oven

A technology for testing coke ovens and mud sealing, which is used in coke ovens, coke oven heating, coke oven doors/closures, etc. It can solve problems such as poor stability, scalding, and large fluctuations in data results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

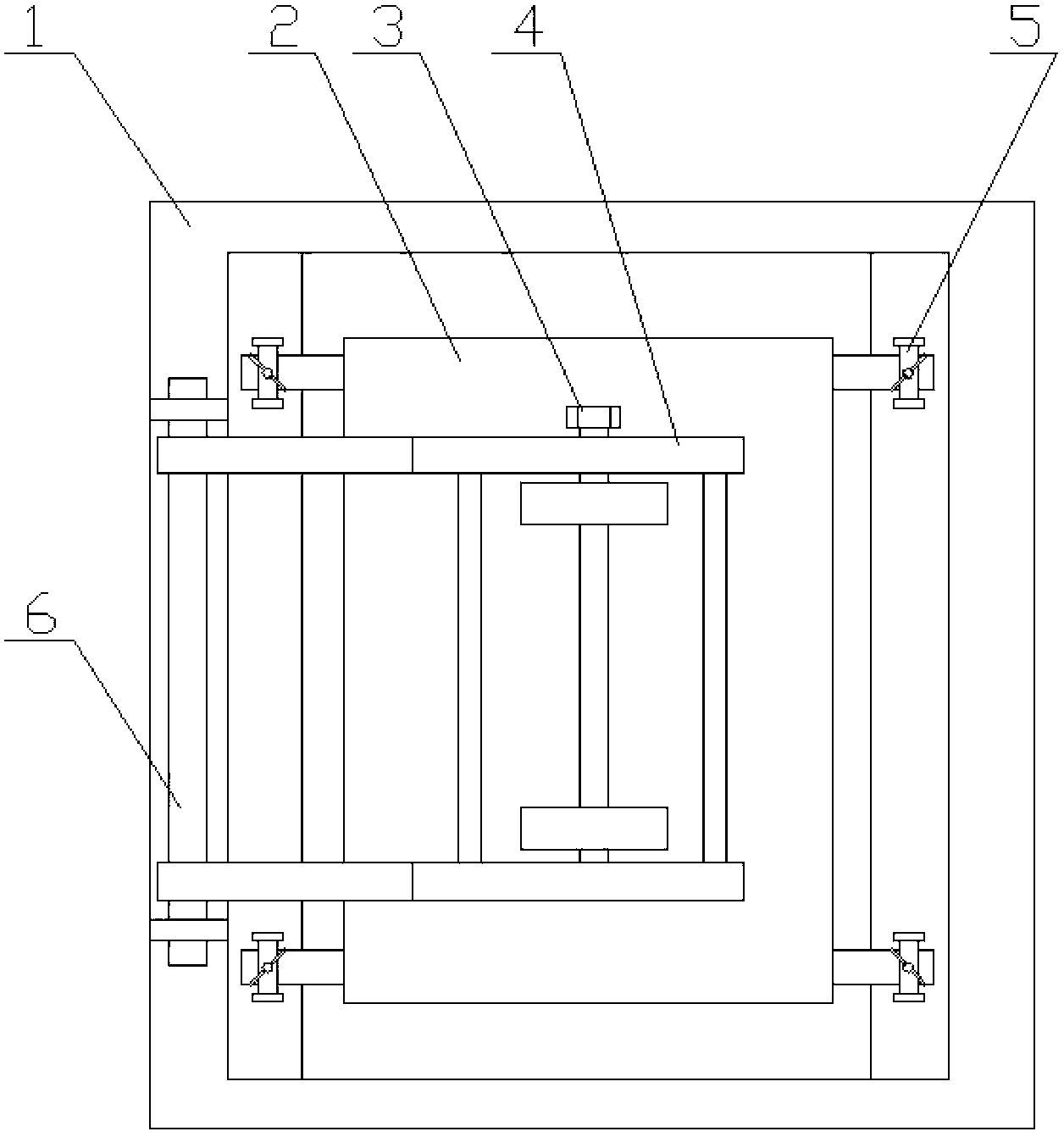

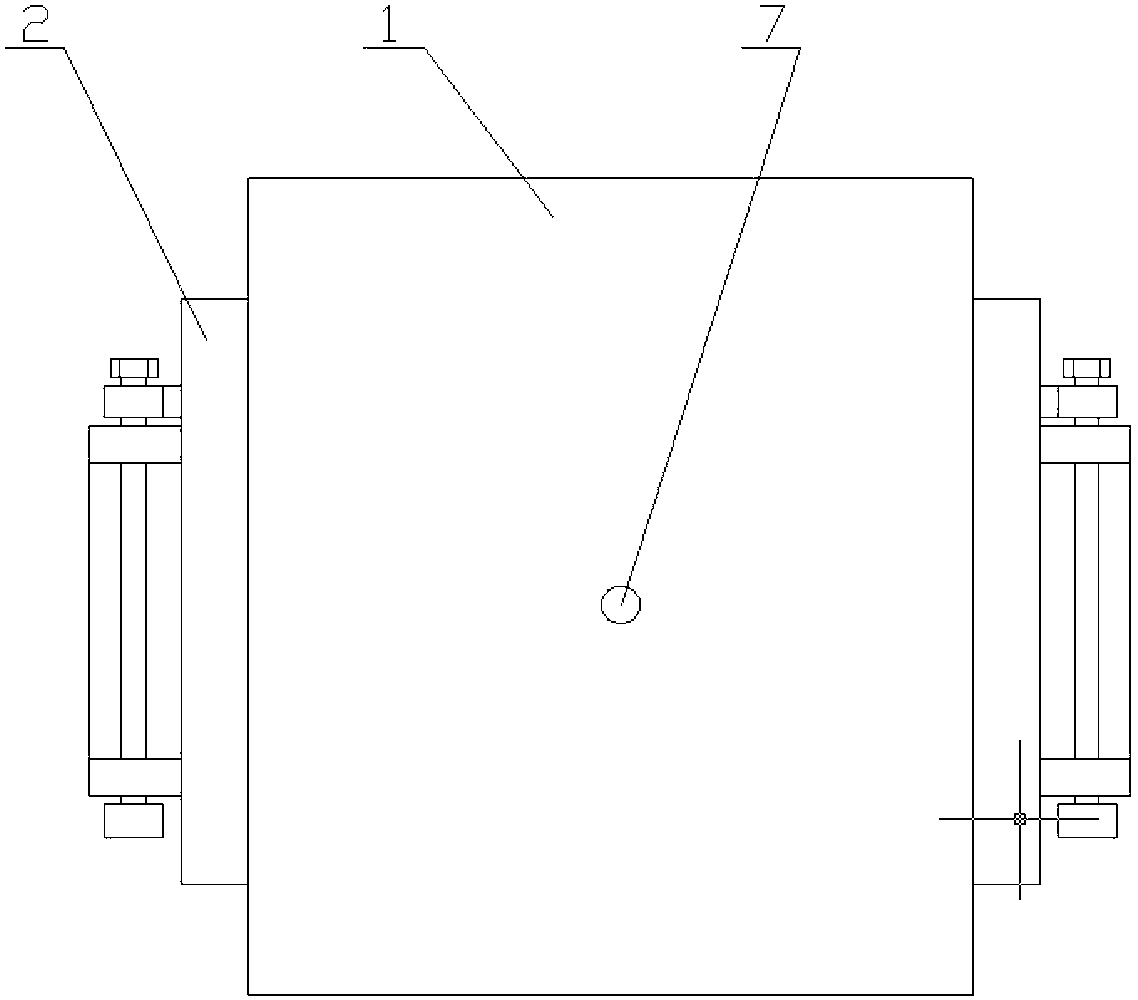

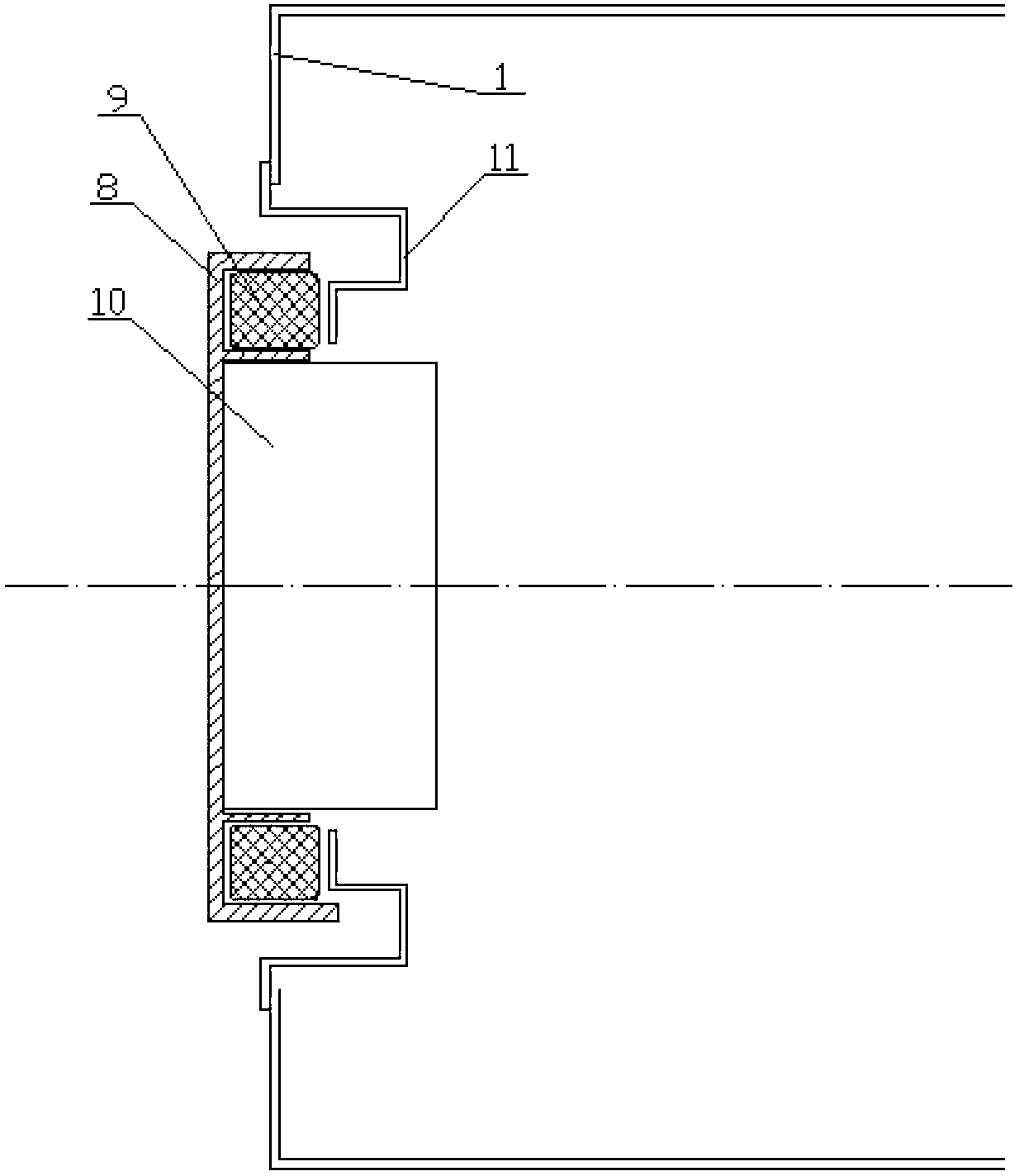

[0027] See figure 1 , figure 2 , image 3 , a mud-seal-free test coke oven, including a furnace body 1, a furnace door 2, a central shaft 3, a support arm 4, a furnace door holder 5, a furnace door hinge 6, a thermocouple 7, and an outer protective steel structure for the furnace door 8 , sealing body 9, furnace door brick 10, steel structure sealing part 11, furnace door includes furnace door outer protection steel structure 8, furnace door brick 10 and sealing body 9, furnace door brick 10 is inlaid in furnace door outer protection steel structure 8 Inside, a ceramic fiber sealing body is provided around the furnace door brick 10; the ceramic fiber sealing body cooperates with the steel structure sealing type 11 at the door of the test coke oven to realize the mud-free type test coke oven door of the seal. The furnace body 1 is provided with a furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com