Drive transistor sructure for ink jet print head chip its making process

A technology for driving transistors and inkjet print heads, which is applied in semiconductor/solid-state device manufacturing, printing, semiconductor devices, etc., and can solve problems such as increased parasitic resistance, high wafer manufacturing costs, and increased heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

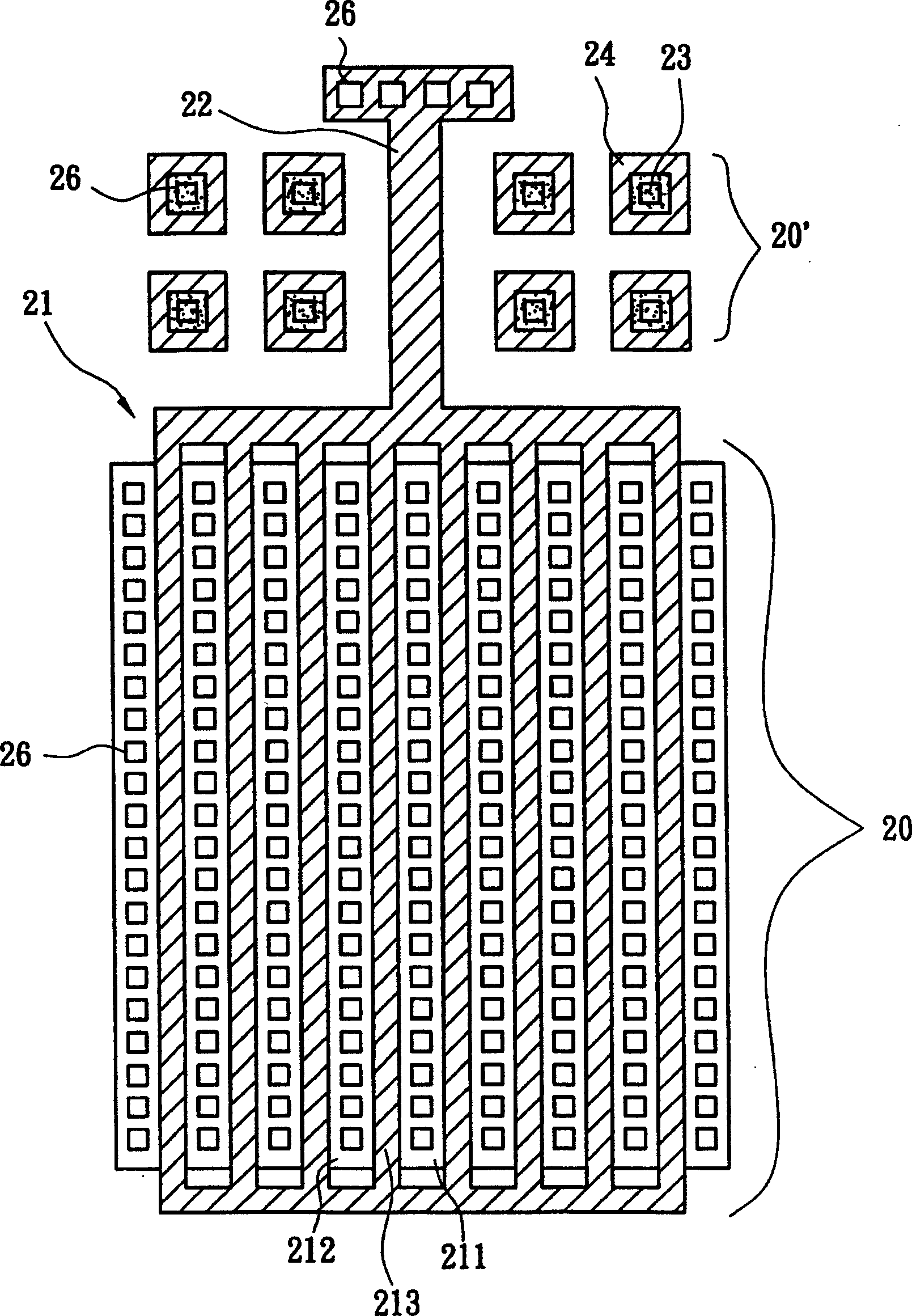

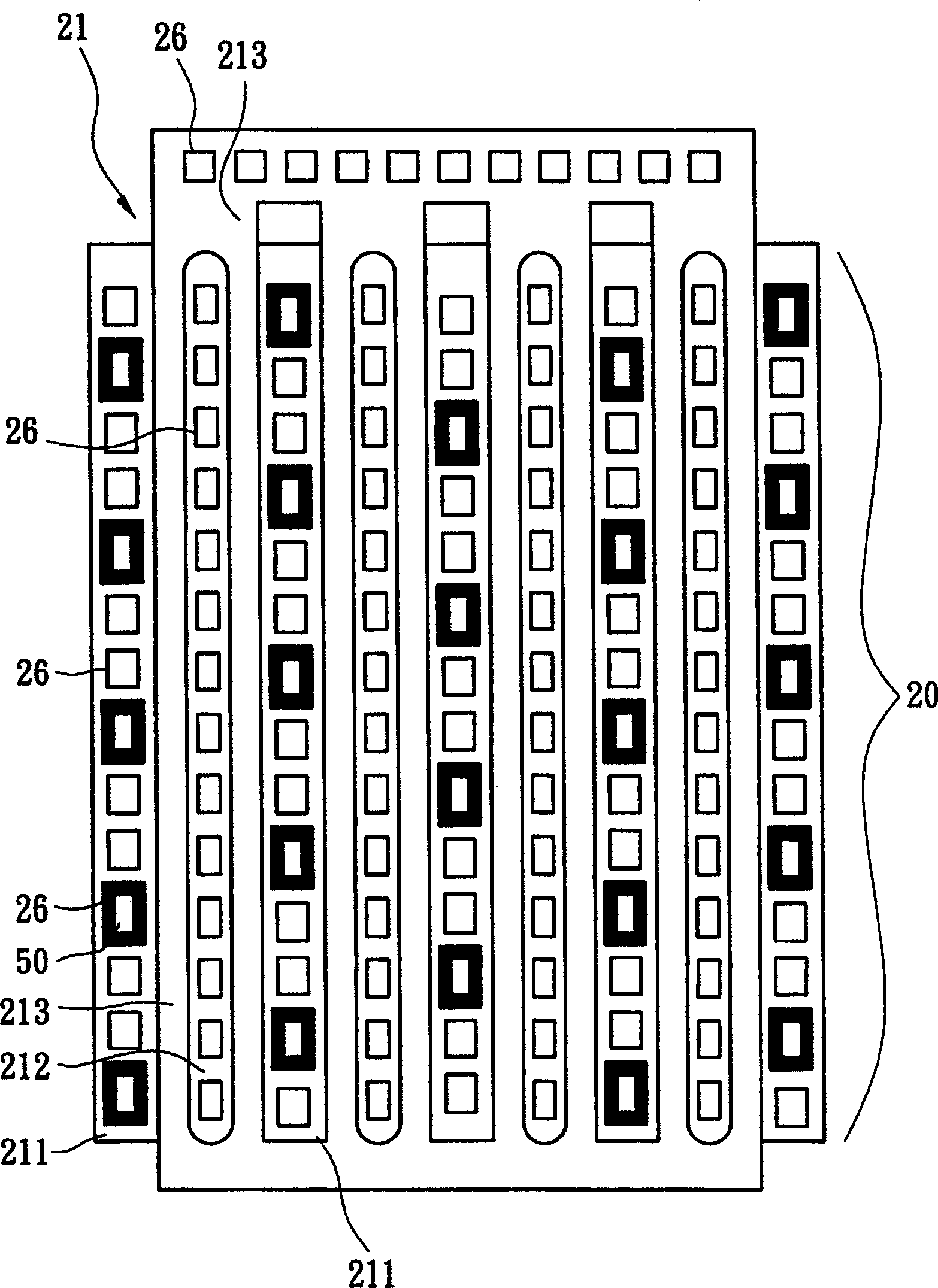

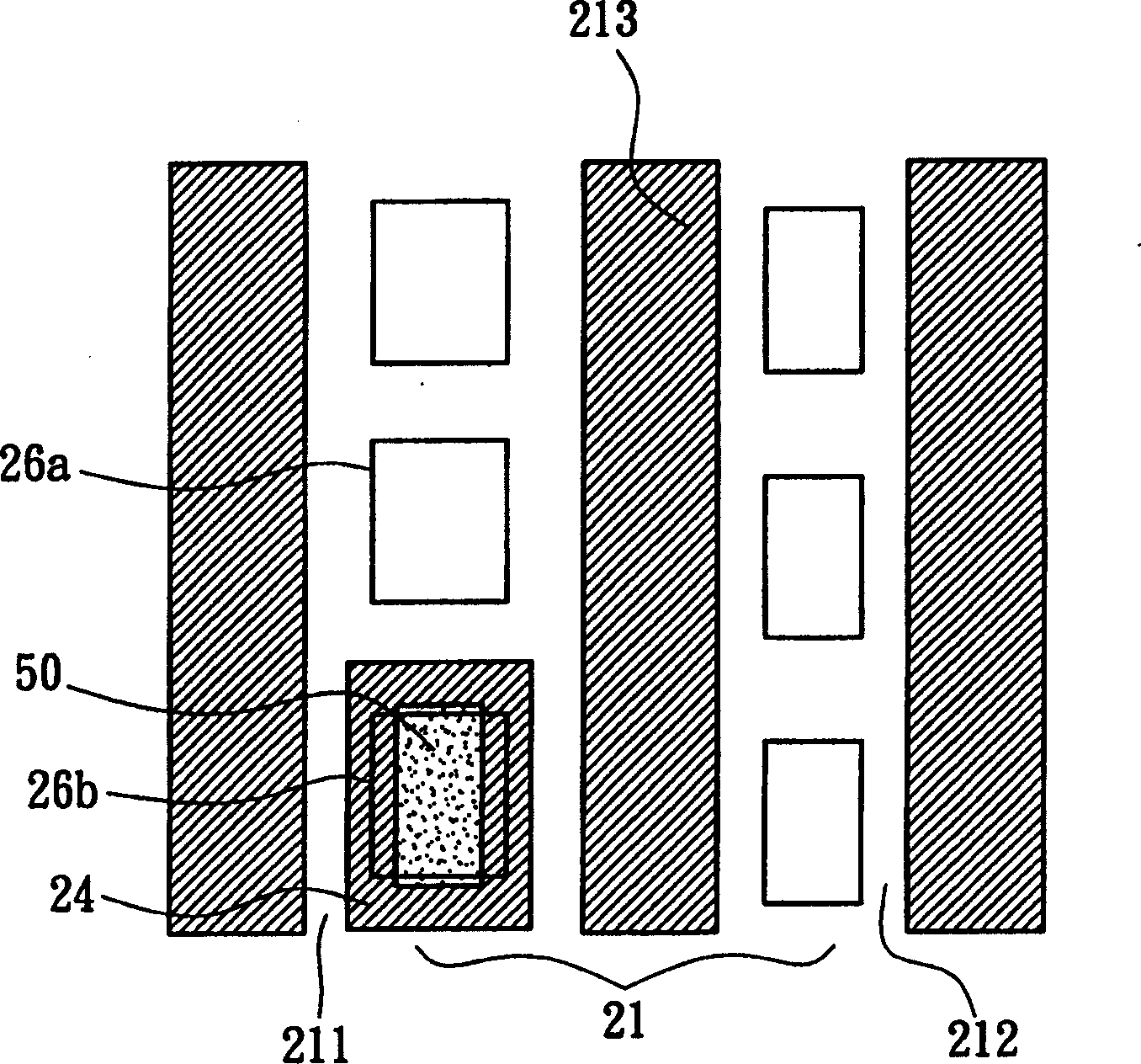

[0020] refer to Figure 2A , which is a schematic top view of the drive transistor structure of the inkjet print head chip according to an embodiment of the present invention, showing a structure layout of the drive transistor with the base embedded in the source (BES). A plurality of bases 50 are disposed in the active region 20 of the drive transistor structure, and the active region 20 has a plurality of MOSFET elements 21 connected in parallel. Each MOSFET element includes: a source region 211 , a drain region 212 and a gate 213 . The plurality of base electrodes 50 are arranged in the source region 211 at a proper distance. Appropriate contact holes 26 are formed on the source region 211 , the drain region 212 , the gate 213 and the base 50 . Since the MOSFET element 21 adopts a design with a large channel width to length ratio, that is, the channel width is much greater than the channel length. Usually, the active region 20 has a width of more than 400 microns. The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com