Fireproofing, antivibration safety house and its production method

A manufacturing method and safe technology, which are applied in the manufacture of earthquake-resistant safe houses and in the field of fire resistance, can solve the problems of decreased overall strength, insufficient impact resistance and safety, and achieve fast and convenient construction, low cost, and protection of life and safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments of the specification.

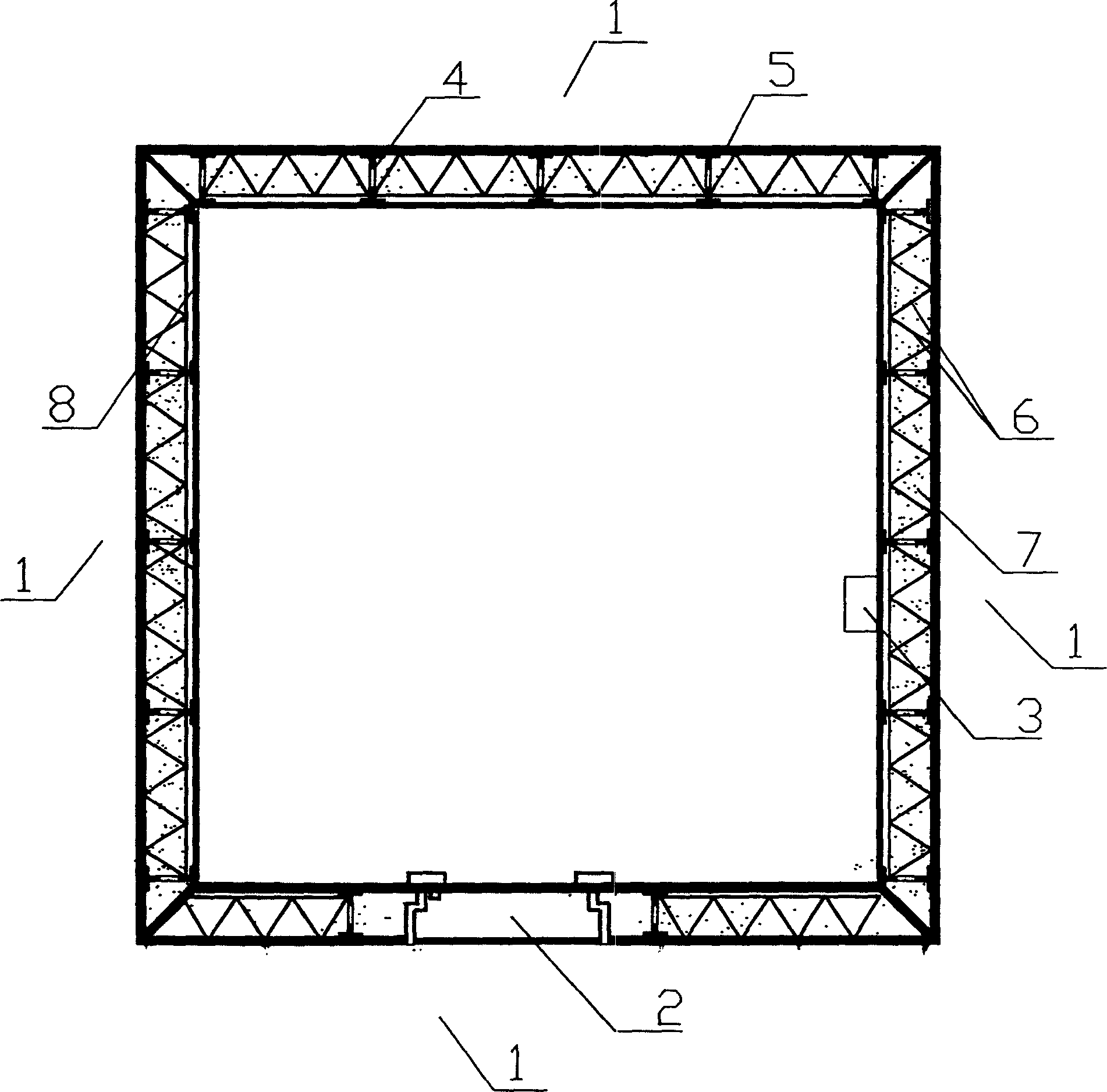

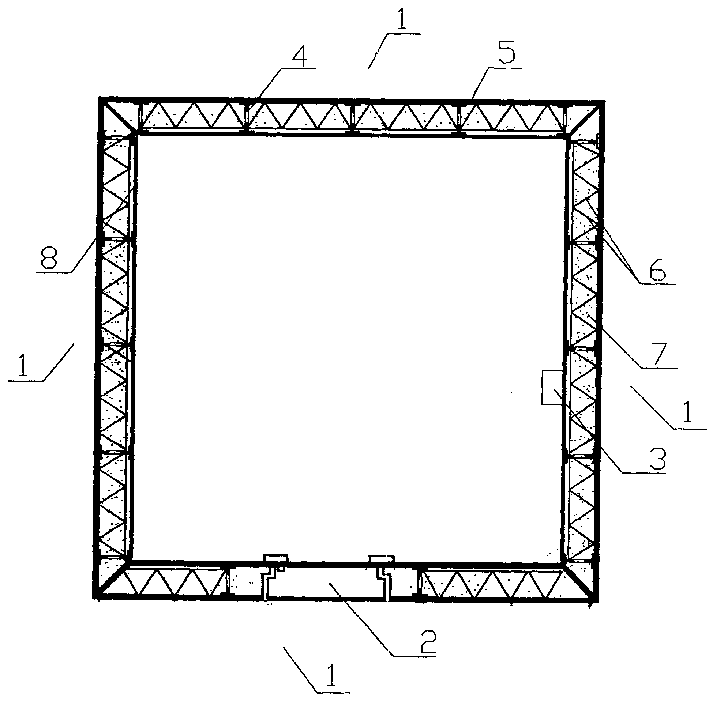

[0034] Such as figure 1 As shown, a fire-resistant, earthquake-resistant safe house is mainly composed of an enclosure structure plate 1, a safety door 2 and auxiliary facilities 3, and is characterized in that: the enclosure structure plate 1 is composed of a steel structure frame 4, an outer steel plate 5. Consisting of mesh reinforced steel structure 6, foamed cement layer 7 and inner surface layer 8; the outer steel plate 5 is welded together with steel structure frame 4 and mesh reinforced steel structure 6.

[0035] The manufacturing method of the present invention comprises:

[0036] 1. First weld the steel structure frame 4, the outer steel plate 5, and the mesh reinforced steel structure 6 into a whole; then effectively connect the inner surface layer 8 with the steel structure frame 4, and the mesh reinforced steel struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com