Plate shape and thickness-controlling rolling method and corresponding gap-less roller mill

A control plate, no gap technology, applied in the direction of metal rolling, contour control, metal rolling, etc., can solve the problems of easy vibration, affecting the accuracy of plate shape and plate thickness control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

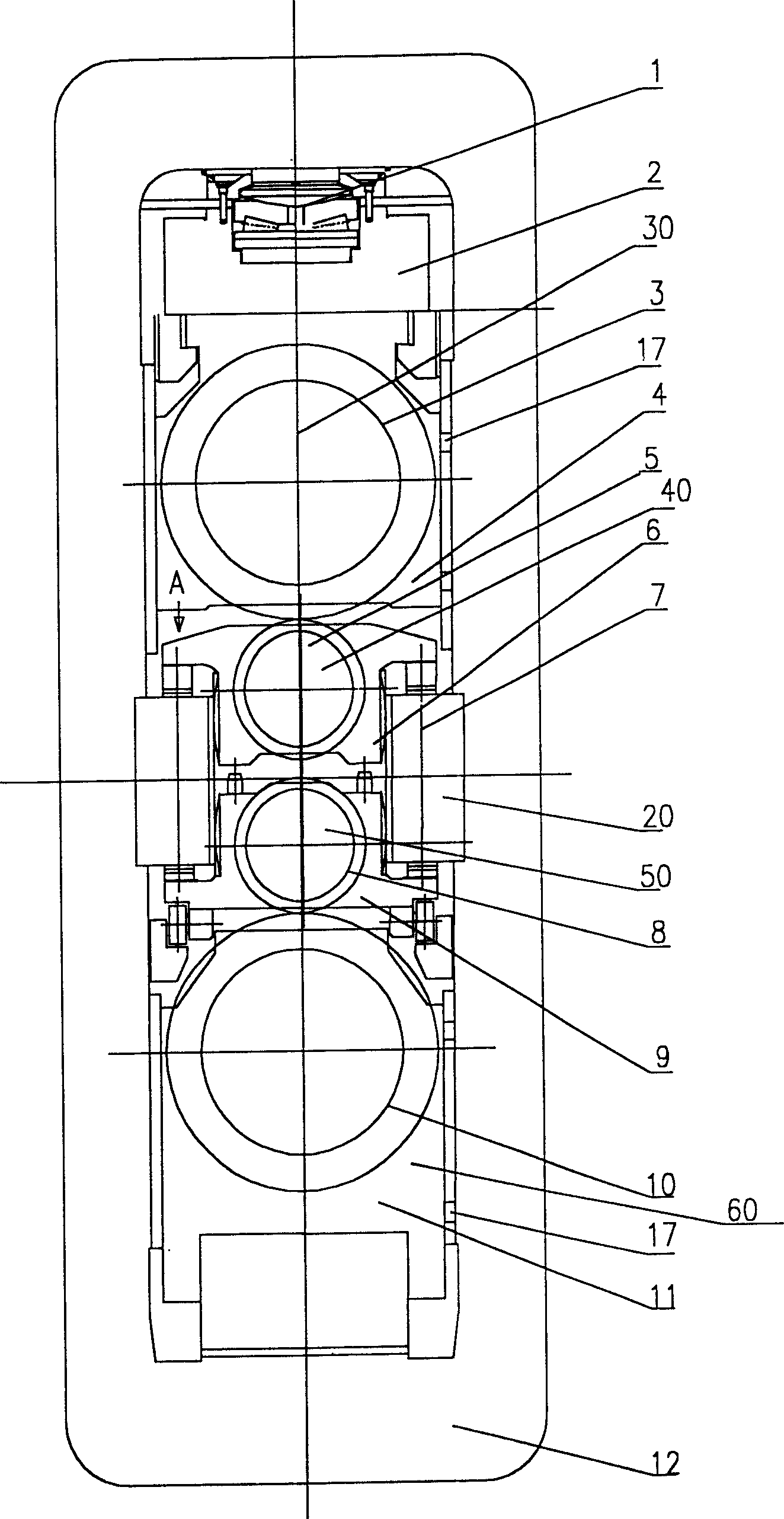

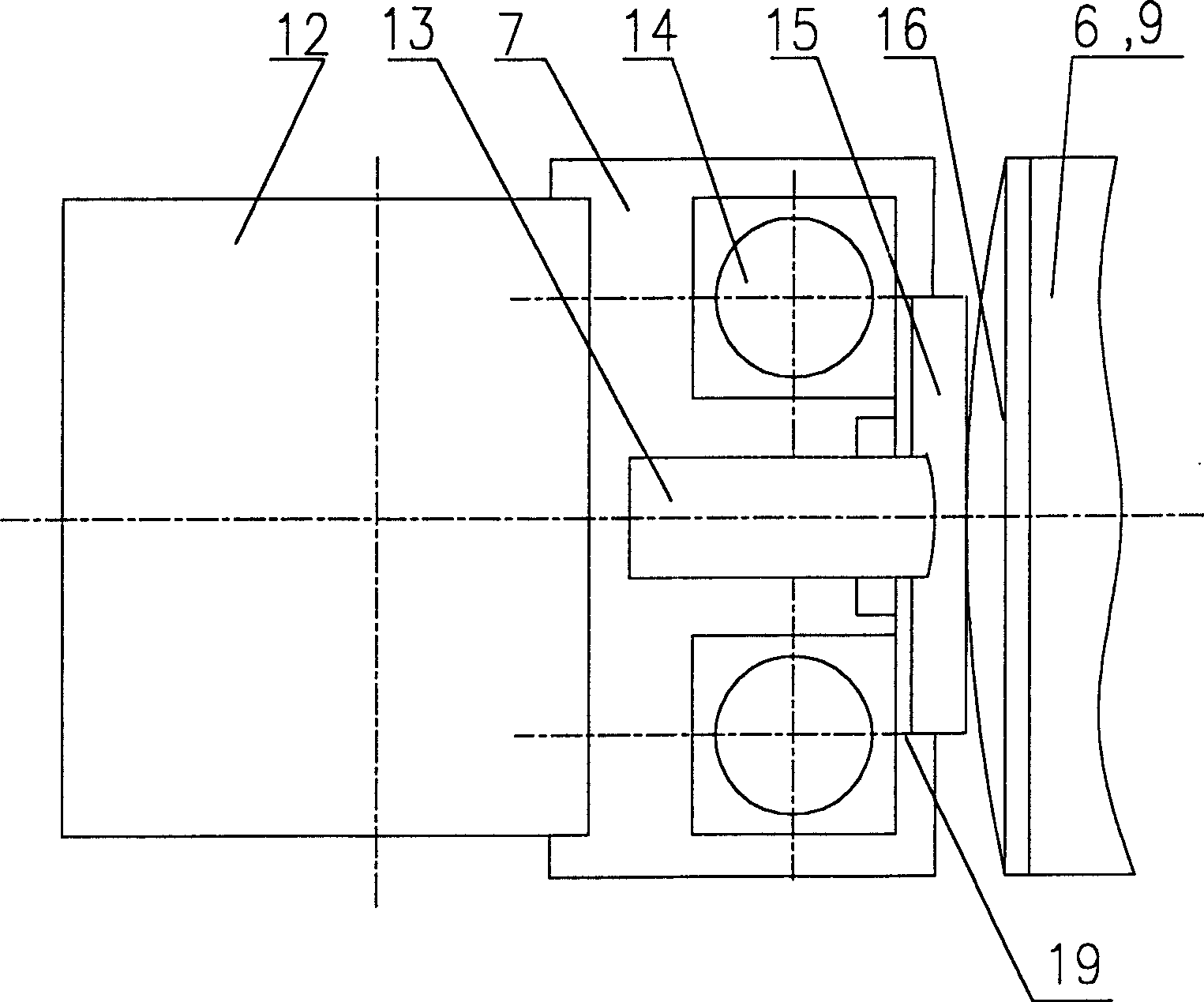

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the drawings and specific implementations:

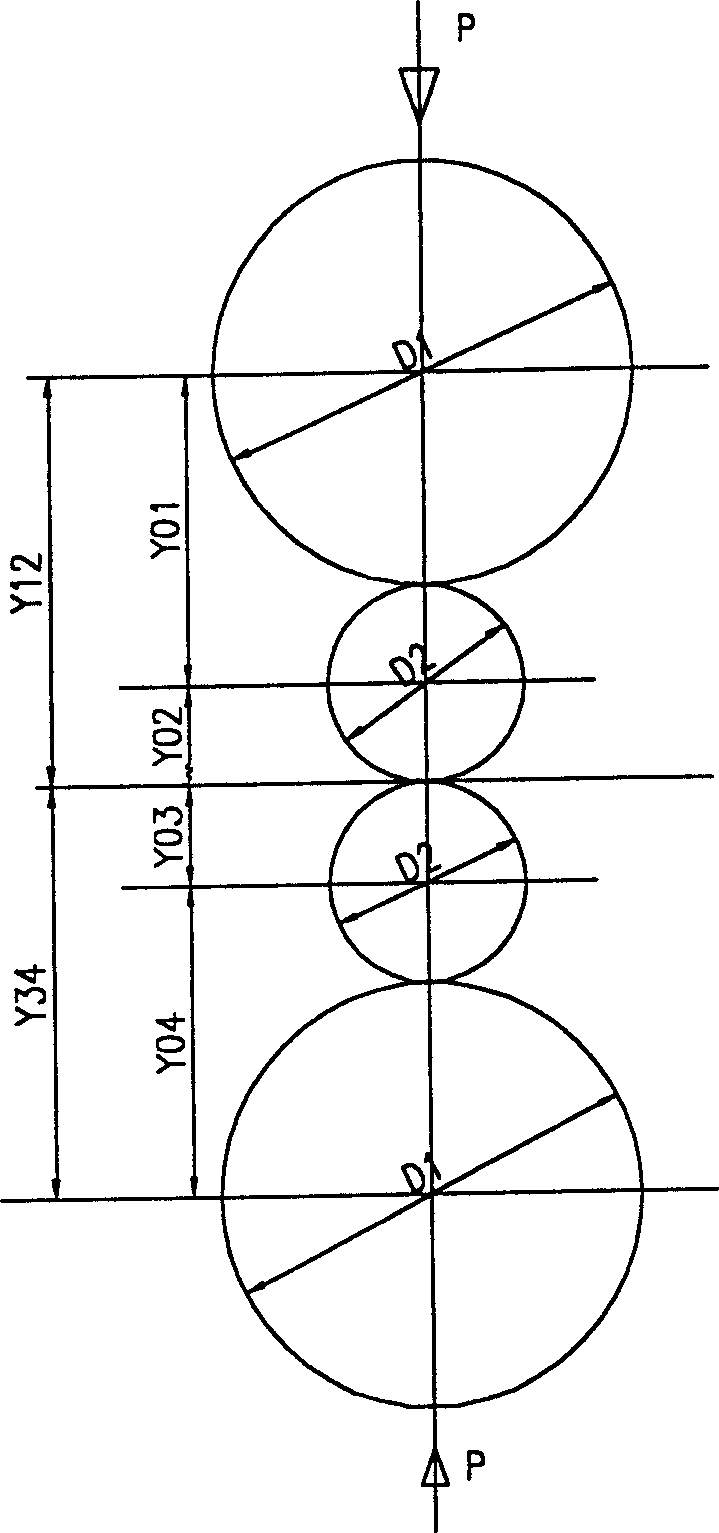

[0023] The method of adjusting the plate shape and thickness of the present invention is to control the plate thickness and plate shape by moving and crossing the work rolls. The movement and crossing of the work rolls refer to the intersection of the upper and lower work rolls and the center lines of the upper and lower support rolls. Respectively cross symmetrically at 1 / 2 of the width of the rolled steel sheet, and the two work rolls move horizontally to the same side at the intersection point, and work at the positions of the two ends of the rolled steel sheet, the axis of one end of the upper work roll and the bottom The axis of the other end of the roller intersects the axis of the support roller respectively. The intersection angle α of the upper and lower work rolls is greater than 0 degree and less than or equal to 1.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com