Principal axis servo controlling method for optical disk drive

An optical disc drive, servo control technology, applied in the recording of information on the magnetic disk, the configuration/installation of instruments, and heads, etc., can solve problems such as obstacles, and achieve the effect of simplification and saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

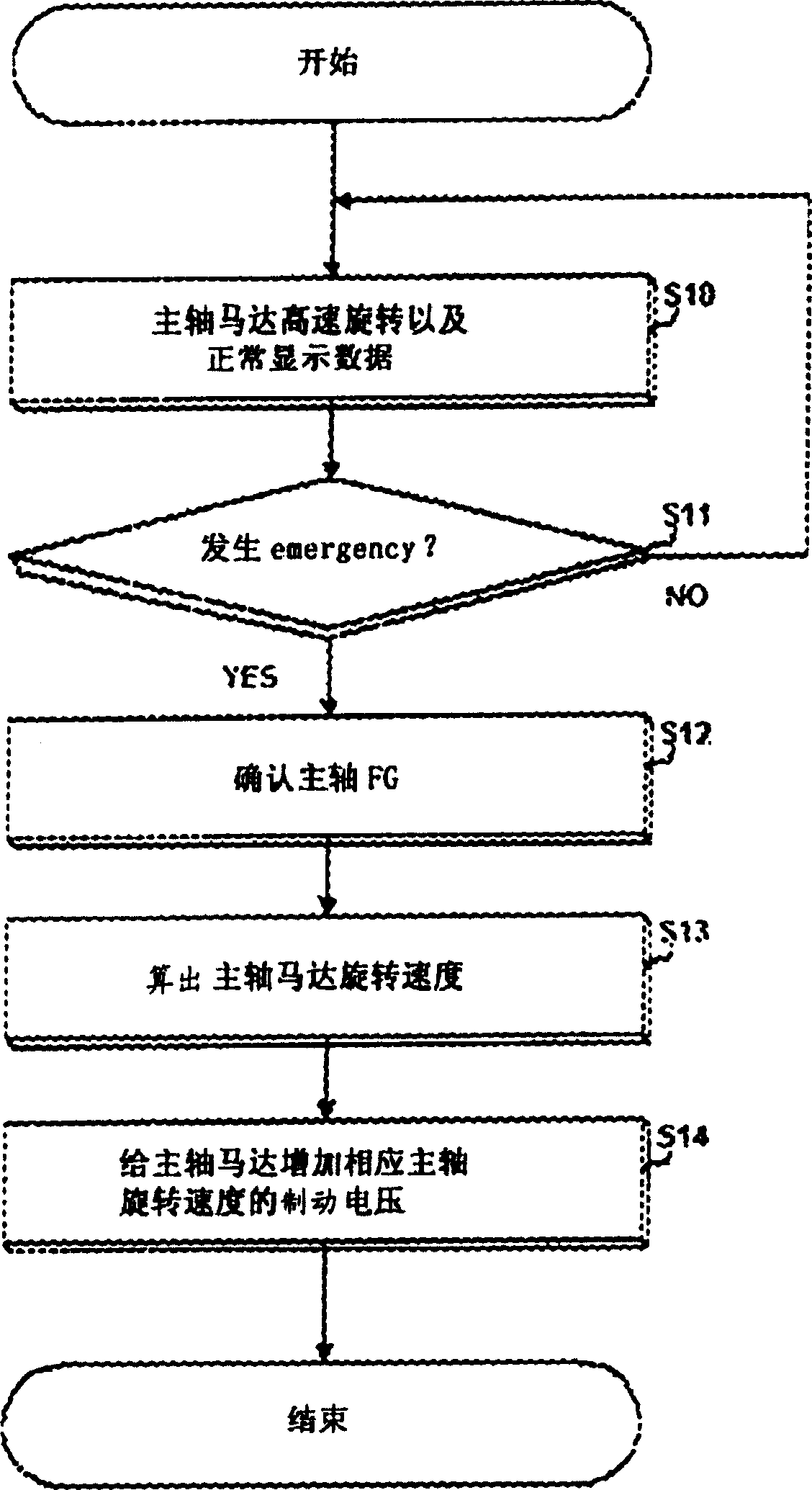

[0029] Embodiments of the spindle servo control method of an optical disk drive according to the present invention will be described in detail below with reference to the accompanying drawings.

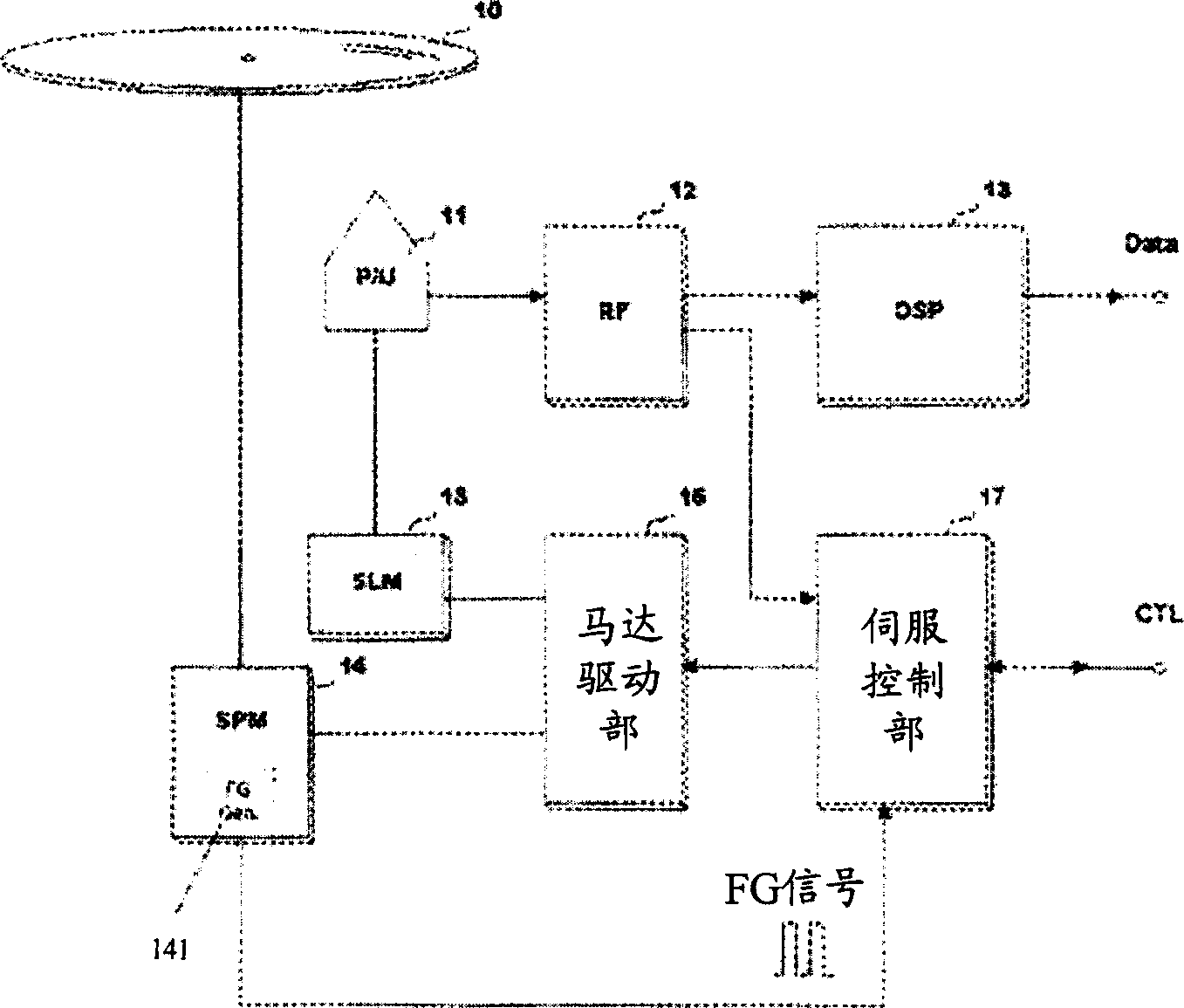

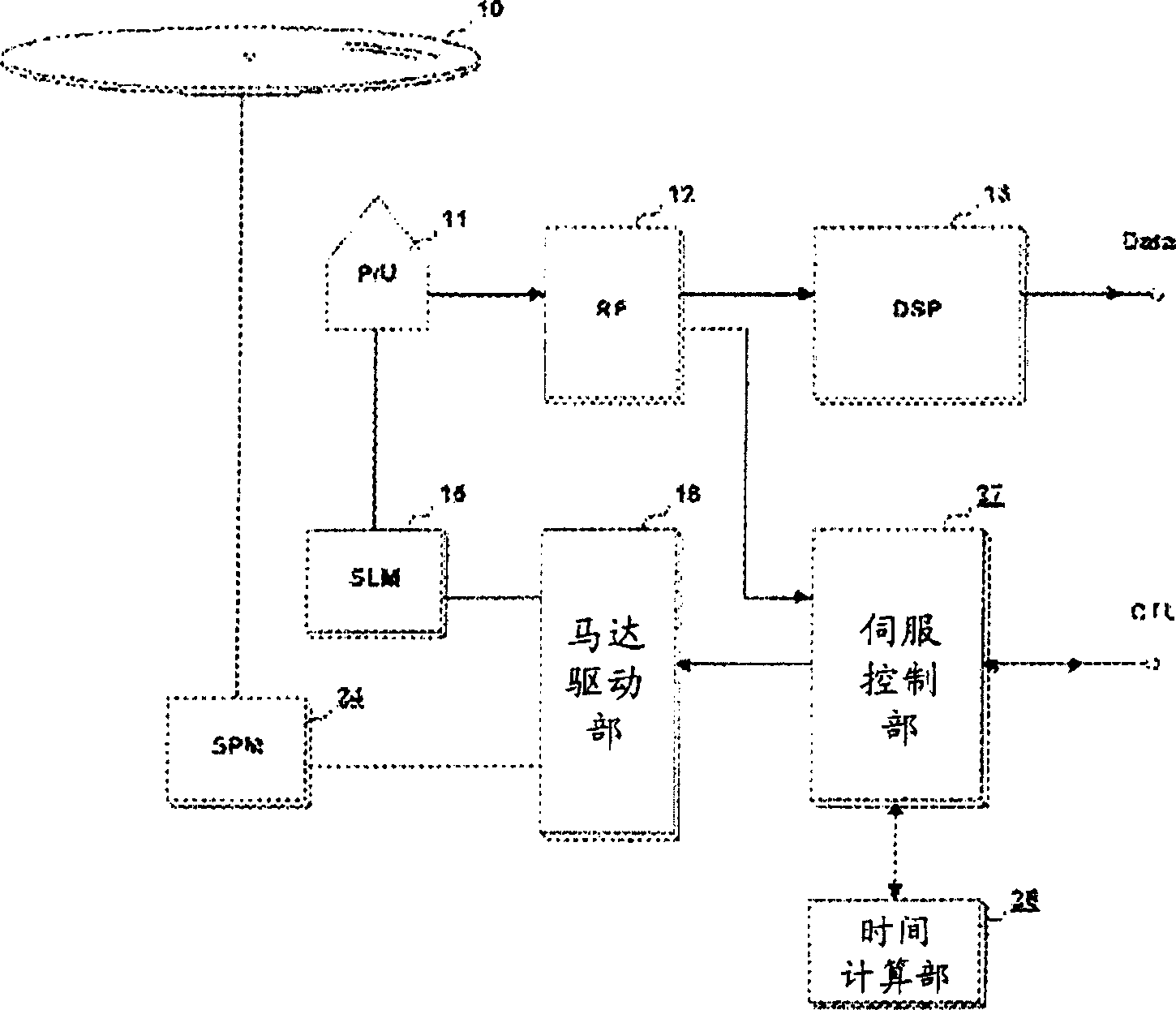

[0030] image 3 is a structural diagram illustrating an optical disc drive manufactured by applying the spindle control method according to the present invention. The above optical disc drive is as referenced figure 1 Description has the following parts.

[0031] The optical pick-up 11 that reads the data that is stored on the optical disc 10 such as CD or DVD; The RF signal that the above-mentioned optical pick-up outputs is processed into the RF signal processing section 12 of the signal of gain and binary (Binary ) and the above-mentioned RF signal The binary signal processed by the processing part 12 is processed into a digital image or a digital signal processing part DSP13 of audio data;

[0032] Spindle motor section SPM24 that rotates the above-mentioned optical disc 10 at h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com