Charging method for nonaqueous electrolyte secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in the direction of non-aqueous electrolyte battery electrodes, non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, etc., can solve the problems of large charging capacity, low usable capacity, uneconomical batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

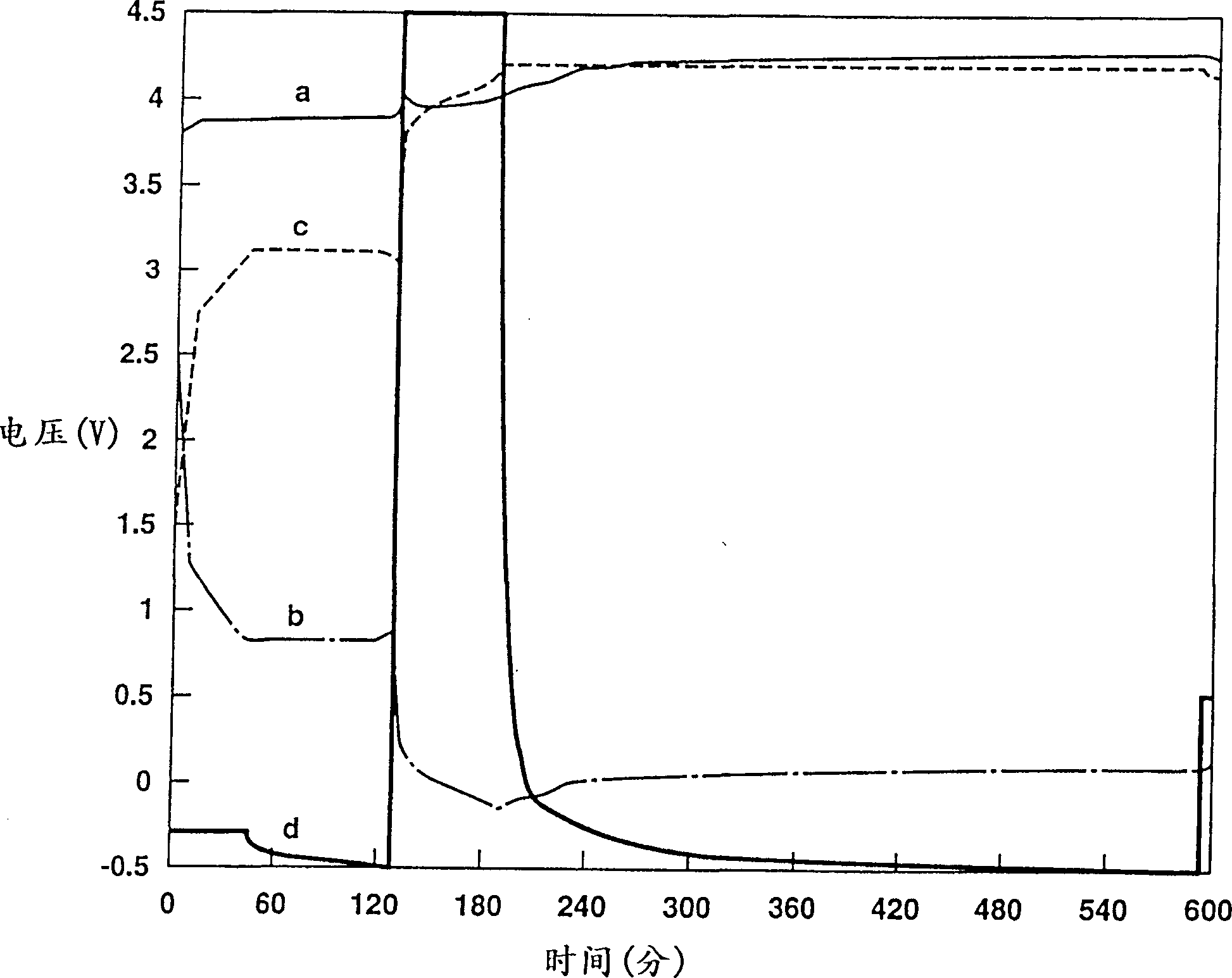

[0024] Now, the charging method provided by the present invention will be described in detail with reference to the accompanying drawings.

[0025] The charging method according to the present invention is based on a basic concept of performing an initial charging process through a charging step having two or more stages. Specifically, a first charging step is performed in which a stable and thin coating layer is formed on the surface of the anode, and then a second charging step is performed in which a charging process is performed to bring the anode potential Below the potential in the first charging step, for example, a charging process is carried out until the battery is fully charged.

[0026] Here, the first charging step is important and the conditions of the first charging step are determined to form a good covering layer.

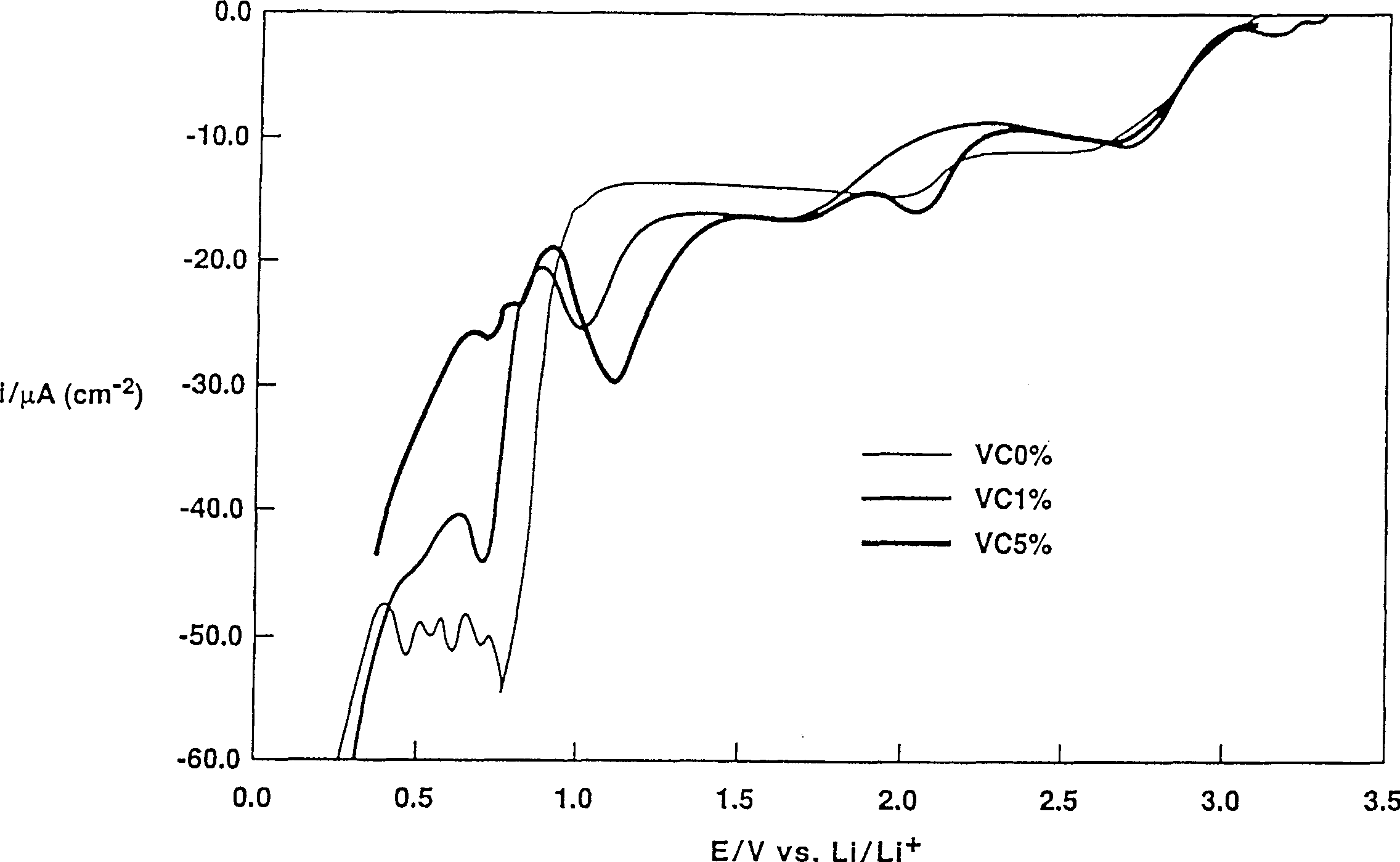

[0027] In the present invention, one or more non-aqueous solvents with a reduction potential higher than that of the main solvent are added to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com