PLC full-automatic controlling steel barrel silk-screen machine

A screen printing machine and steel drum technology, applied in screen printing machines, printing machines, rotary printing machines, etc., can solve problems such as blurred printing, difficult high-speed control of printing, and sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

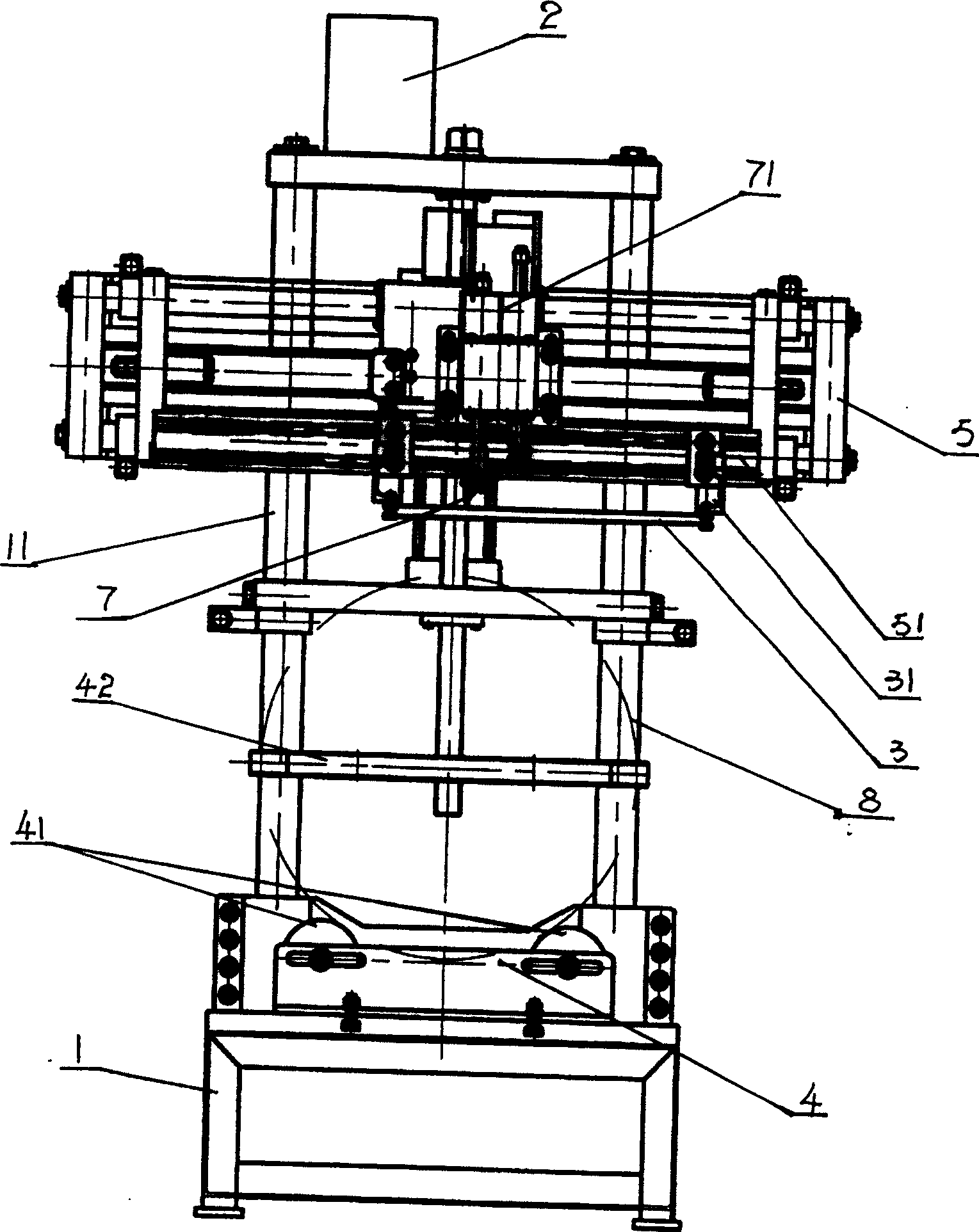

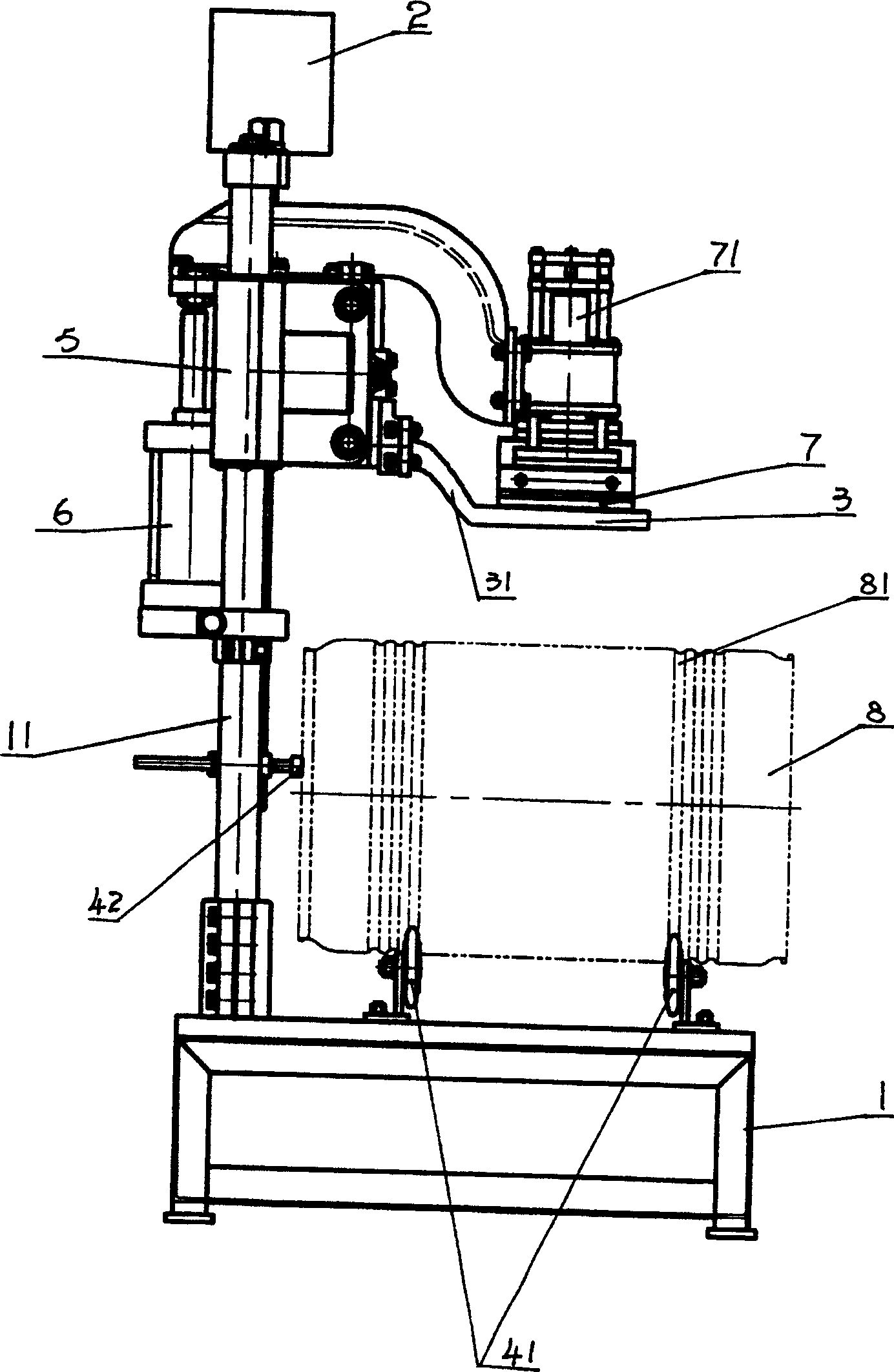

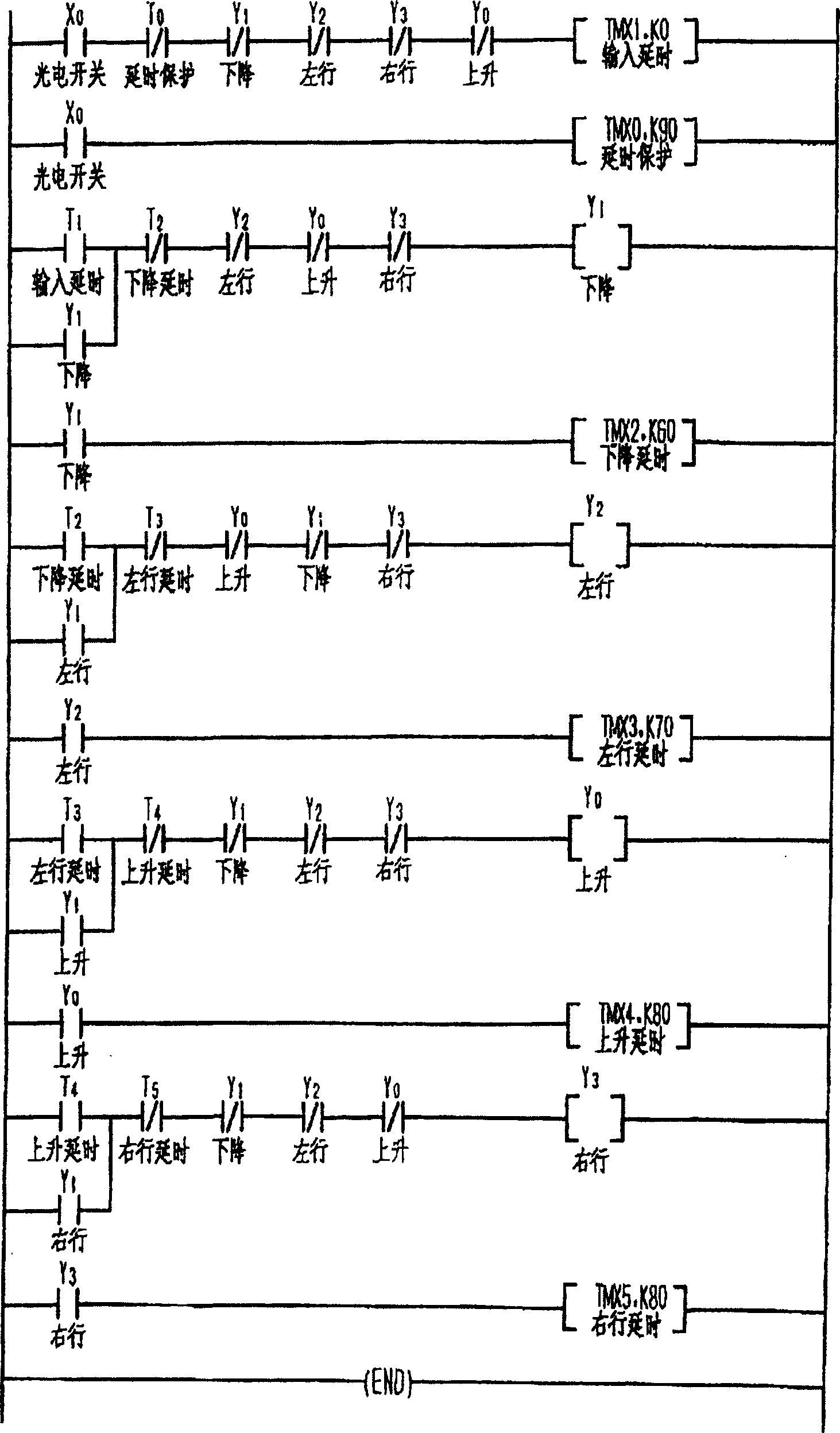

[0012] See attached figure 1 , 2 , the present invention includes organic base 1, PLC controller 2 and screen plate 3, PLC controller 2 is installed on the frame 11 of machine base 1, and controls the power mechanism of screen printing machine by it. The upper end surface of the base 1 is provided with some positioning rollers 41 arranged in parallel, and the frame 11 on the rear side of the base 1 is provided with a positioning block 42 cooperating with the positioning rollers 41. The positioning block 42 is a strip shape, which spans the The frame 11 is not on the same plane as the positioning roller 41, and the positioning block 42 supports the end of the steel drum 8. There is an adjustable connection between the positioning rollers 41 and the machine base 1. The positioning rollers 41 are arranged in a regular quadrilateral. The distance between the two horizontal positioning rollers 41 is smaller than the diameter of the printing steel drum 8. At the same time, the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com