High sensitivity pressure sensor with long term stability

A pressure sensor, high-sensitivity technology, applied in the pressure difference measurement between multiple valves, fluid pressure measurement using capacitance changes, fluid pressure measurement, etc., to achieve the effect of providing long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In addition to the preferred embodiment or embodiments disclosed below, the invention is capable of other embodiments and of being practiced or carried out in various ways. It should therefore be understood that the application of the present invention is not limited to the detailed construction and arrangement of parts set forth in the following description or drawings.

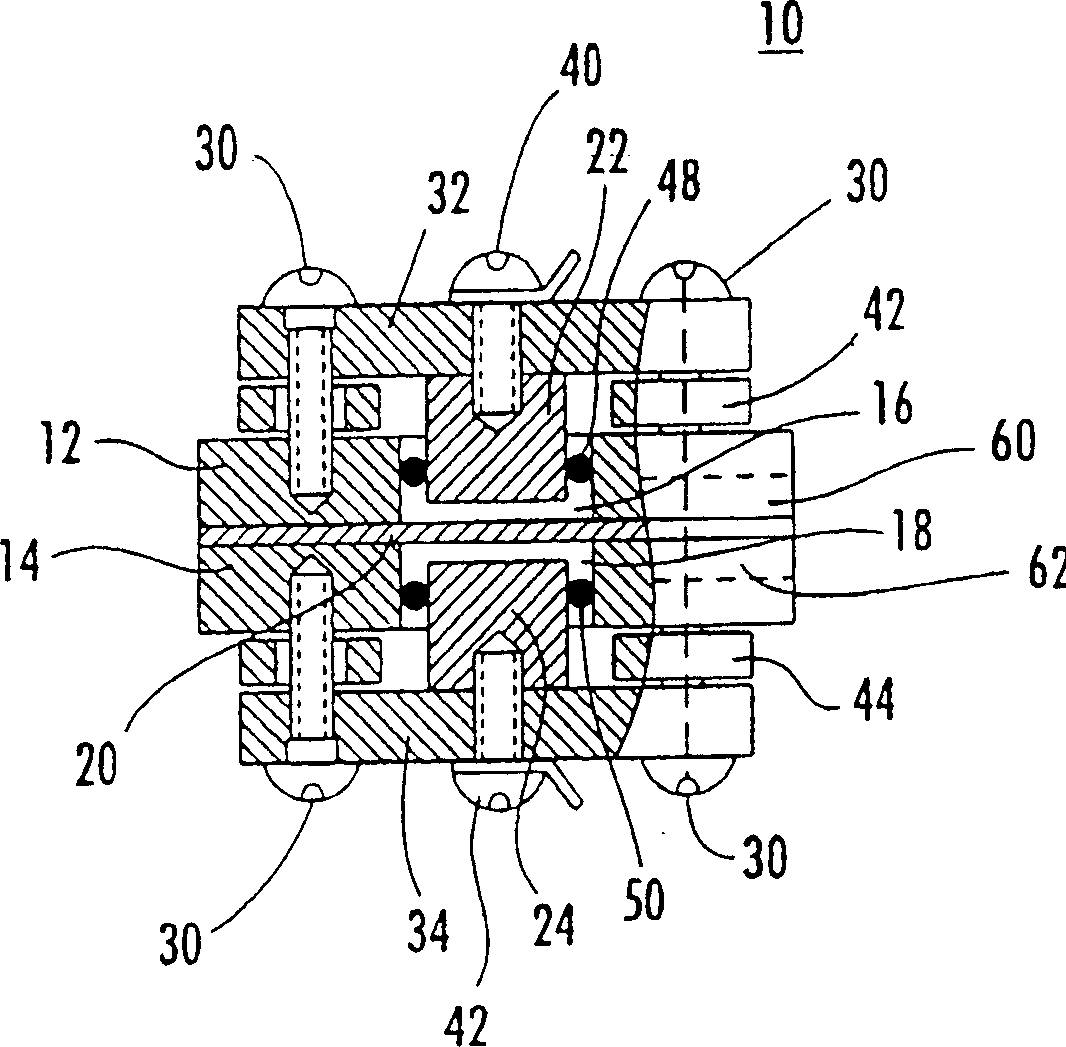

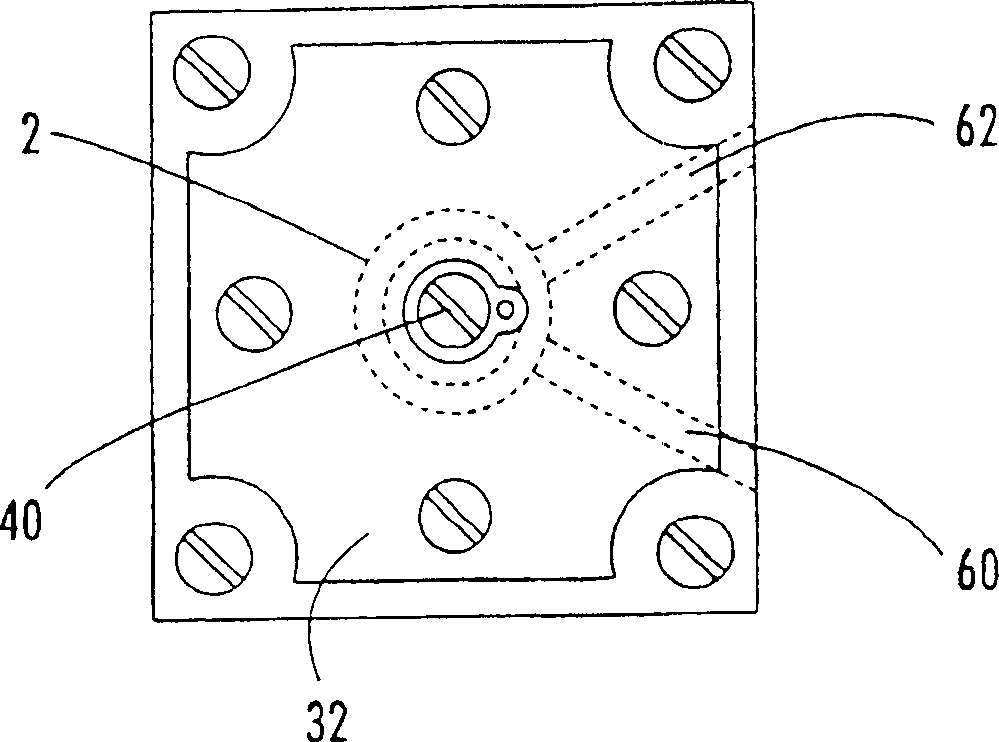

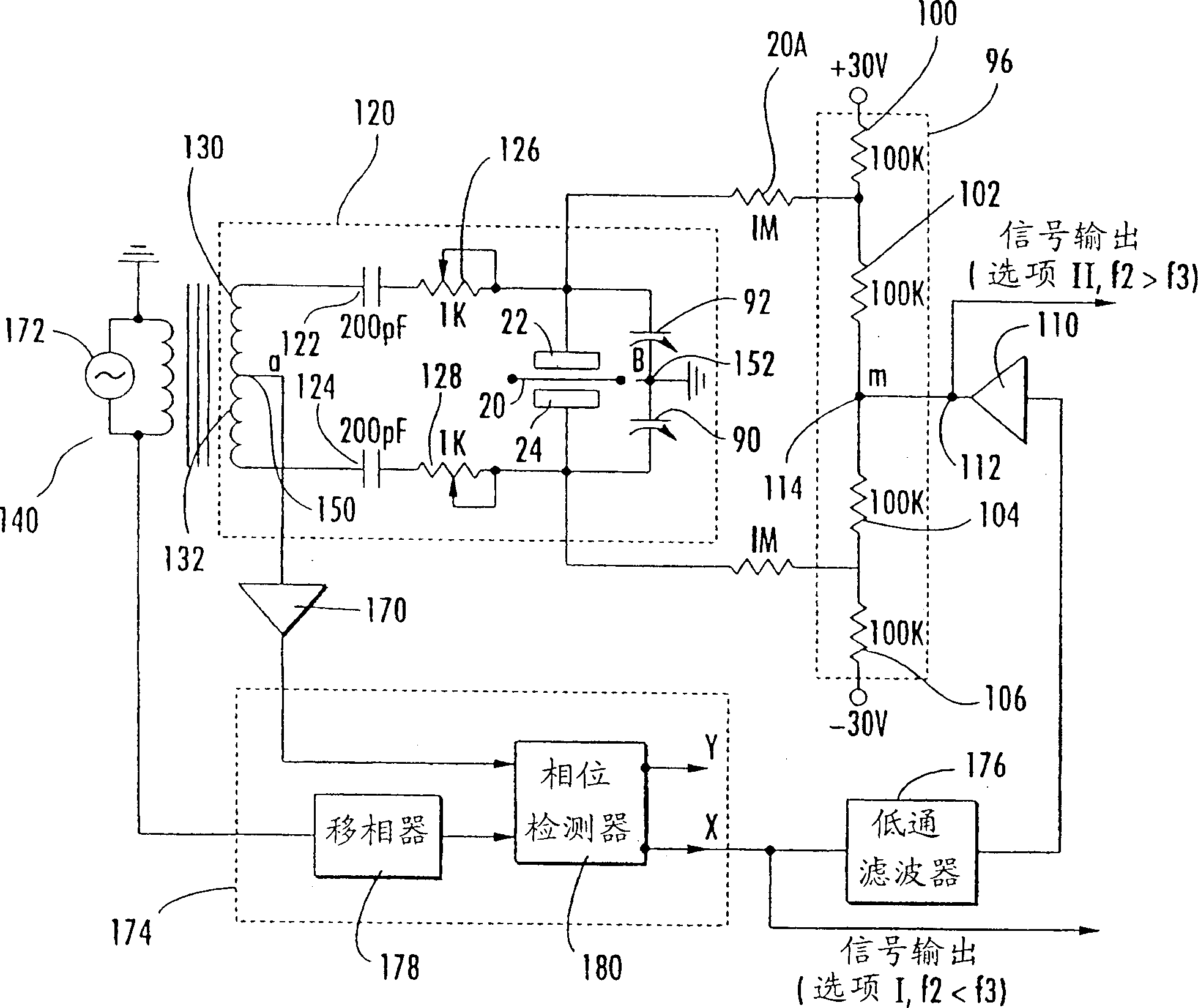

[0031] of the present invention Figure 1-2 The pressure sensor 10 preferably includes a housing having two base plates 12 and 14 defining a first chamber 16 and a second chamber 18 of equal volume. Diaphragm 20 separates and spans chambers 16 and 18 and is clamped between substrates 12 and 14 . A first electrode 22 is located in the first chamber 16, closely spaced from one side of the diaphragm 20 to form a first capacitor therewith. A second electrode 24 is located in the second chamber 18, closely spaced from the opposite face of the diaphragm 20 to form a second capacitor therewith.

[0032] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com