Direct drive light-emitting diode (LED) driver

A technology of light-emitting diodes and light-emitting diode lamps, applied in the electronic field, can solve problems such as low loop bandwidth, low commonality, and poor loop stability, and achieve improved loop stability and loop bandwidth, reduced voltage ripple and electromagnetic interference, and high The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

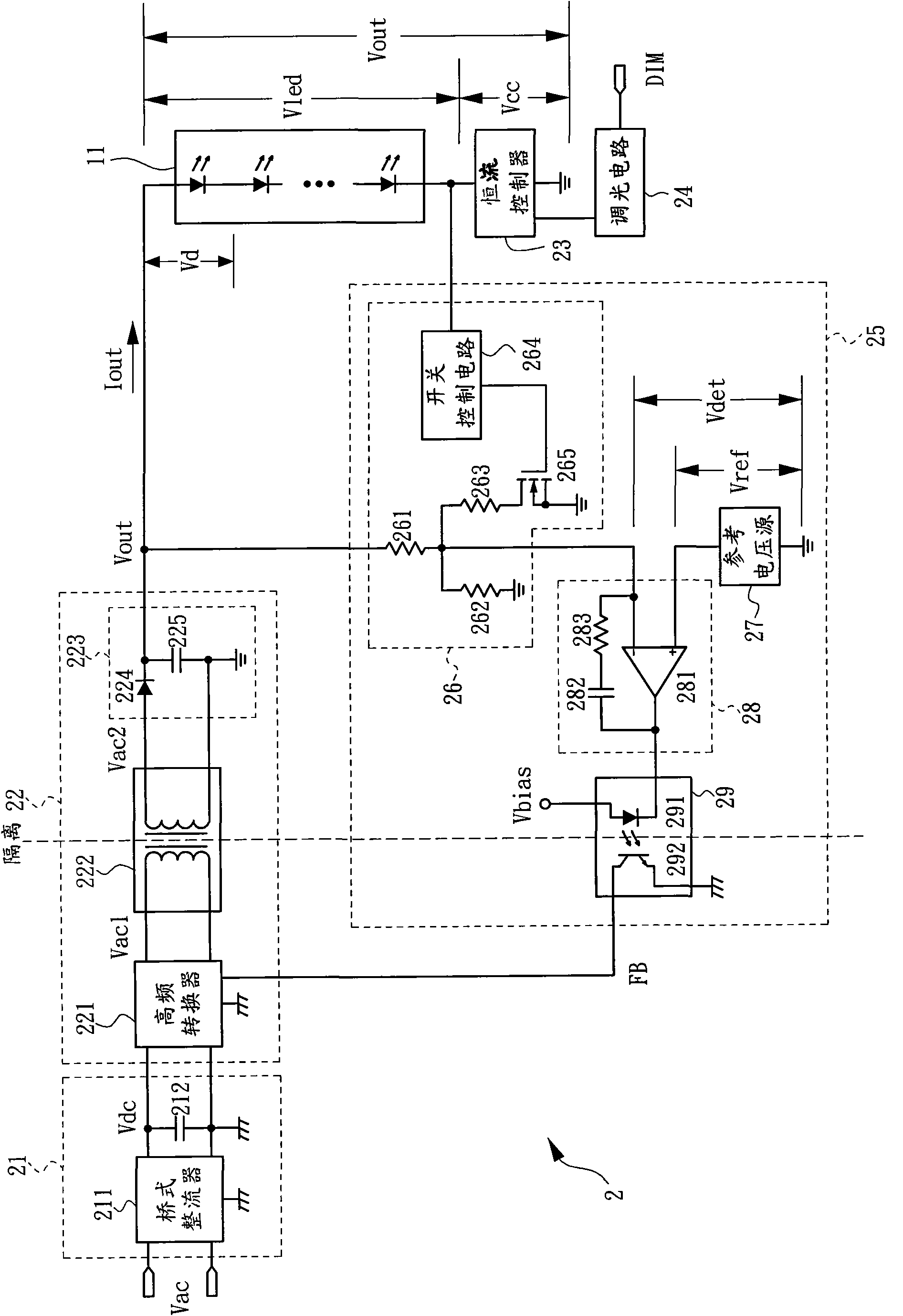

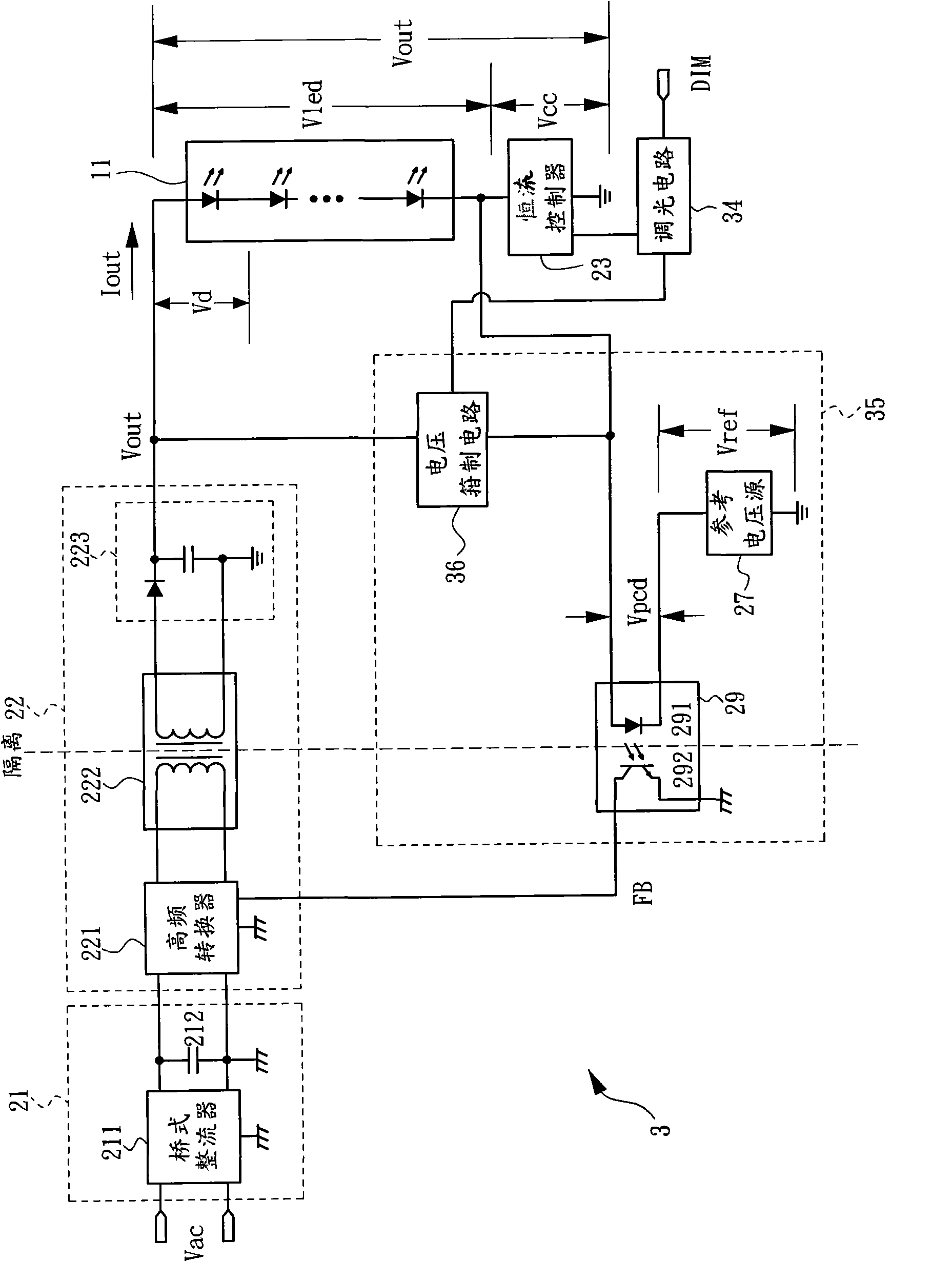

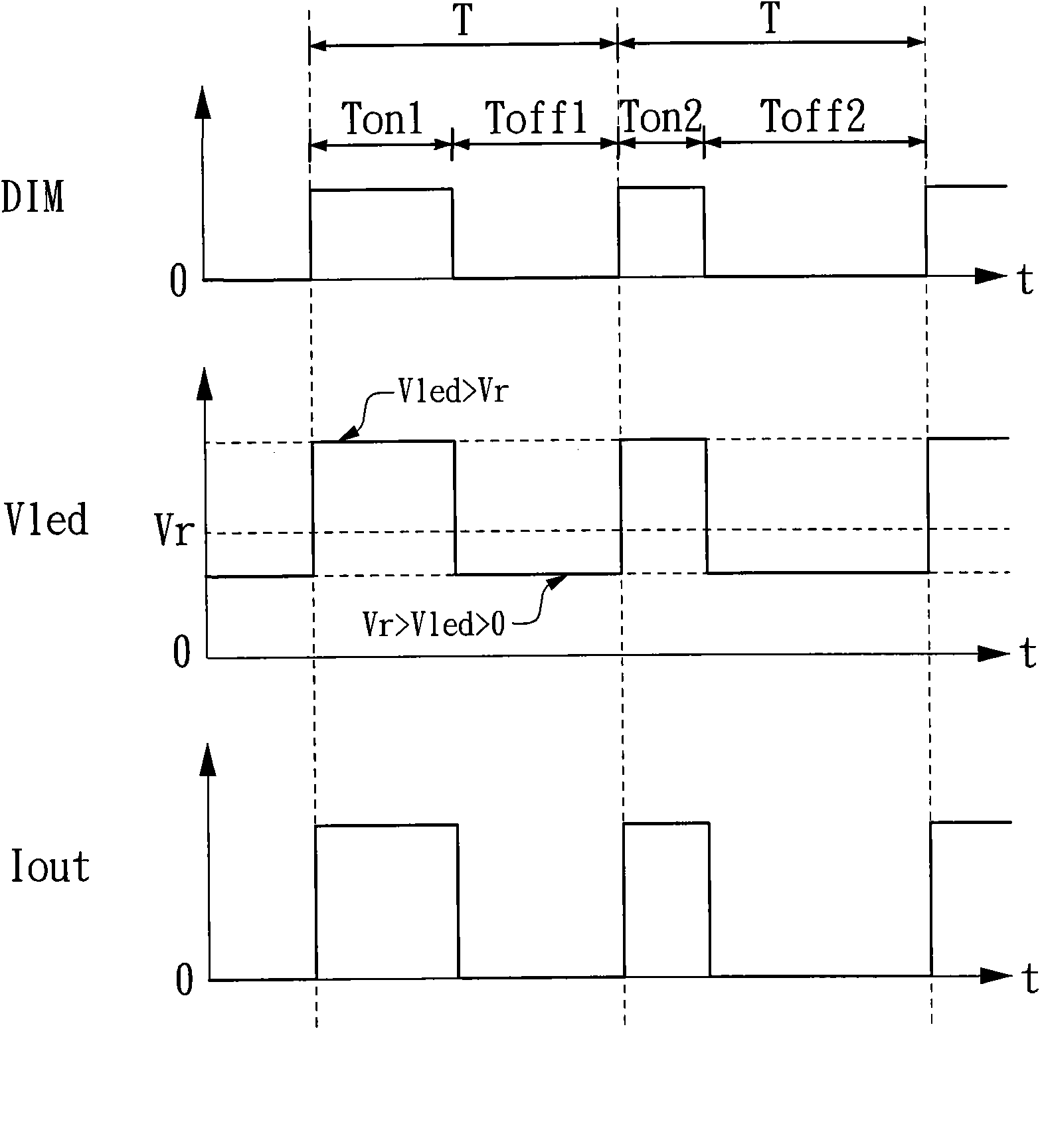

[0047] figure 2 is a circuit block diagram of the first embodiment of the direct-drive LED driver according to the present invention, image 3 for figure 2 The timing diagram of the dimming control of the direct-drive LED driver shown. See figure 2 , the LED lamp string 11 is composed of a plurality of LEDs coupled in series and has an input terminal and an output terminal. The direct drive LED driver 3 is used to receive the AC power Vac and the dimming signal DIM to drive the LED lamp string 11, wherein the dimming signal DIM is as image 3 As shown, each period T includes an enabling period and a disabling period, for example, the first period T includes an enabling period Ton1 and a disabling period Toff1, and the second period T includes an enabling period Ton2 and a disabling period Toff2, T=Ton1+Toff1=Ton2+Toff2. The direct-drive LED driver 3 includes an input rectifying filter 21, an isolated DC-to-DC converter 22, a constant current controller 23, a dimming ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com