Ti-Si carbide powder and its normal pressure synthesis process with Al as reaction assistant

A technology of reaction assistant and carbide powder, applied in the field of titanium silicon carbide powder and its synthesis, can solve the problems such as scratches on the surface of abrasives, adverse effects of material properties, and inability to meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0019] Weigh 35.92 grams of titanium Ti powder, 7.02 grams of silicon Si powder, 6.01 grams of graphite powder, and 1.35 grams of aluminum Al powder, mix them in 50 grams of absolute ethanol medium, use agate ball milling for 4 hours, and bake in an oven at 60 °C After drying, grind, sieve, put into graphite mould, compact under 8MPa pressure, put into high temperature furnace, protect with argon, heat up to 1450°C at a rate of 20°C / min, keep warm for 8min, and heat for 10~ The furnace temperature was lowered to 60°C at a rate of 15°C / min, and the loose block formed by the reaction was taken out and ground to obtain Ti 3 SiC 2 Titanium silicon carbide powder with phase volume content greater than 98%.

Embodiment approach 2

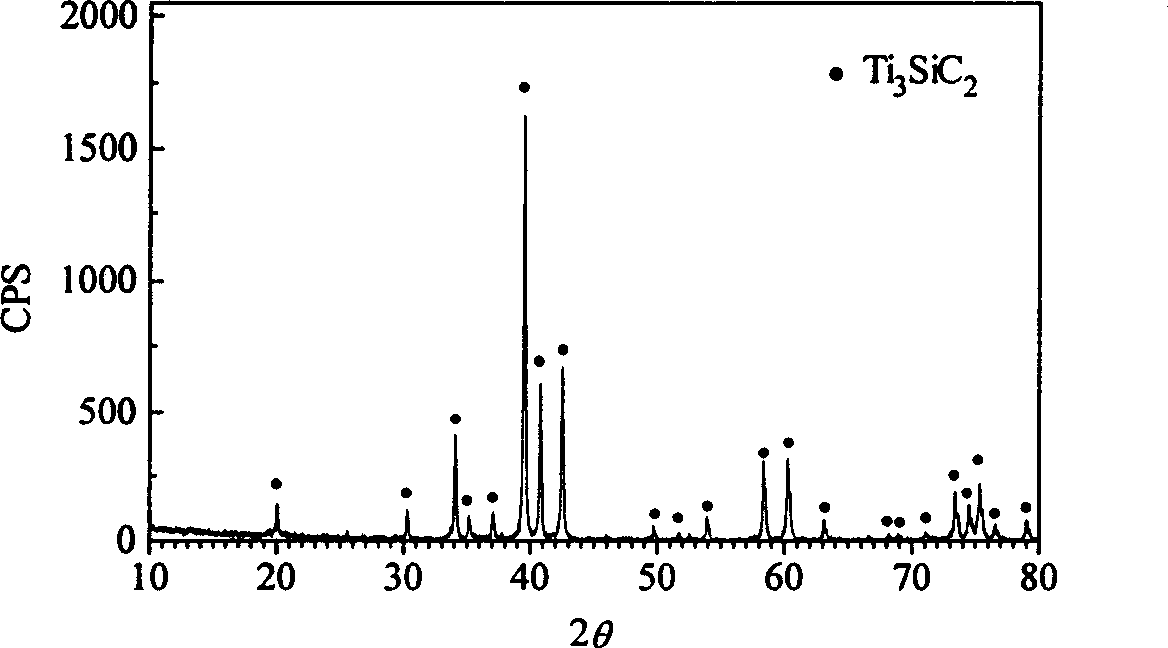

[0021] Weigh 143.64 grams of titanium Ti powder, 28.09 grams of silicon Si powder, 24.02 grams of graphite powder, and 5.40 grams of Al powder, mix them in 50 grams of absolute ethanol medium, use agate ball milling for 2 hours, and dry them in an oven at 60 °C Finally, grind and sieve, put into graphite mold, compact under 8MPa pressure, put into high-temperature furnace, protect with argon, heat up to 1450°C at a rate of 40°C / min, keep it warm for 5min, and keep it for 10-15 The rate of ℃ / min lowers the furnace temperature to 60 ℃, and the loose block formed by the reaction is taken out and crushed to obtain Ti 3 SiC 2 Titanium silicon carbide powder with a phase volume content greater than 99%. Its X-ray diffraction pattern is as attached figure 1 As shown, it can be seen from the figure that only Ti 3 SiC 2 diffraction peaks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com