Automatic purging system in water-ballast condenser line pipes

An automatic cleaning and condenser technology, applied in the field of cleaning systems, can solve the problems of insufficient ball return, waste of water resources, expensive use costs, etc., to prevent a large amount of loss, ensure the cleaning effect, and reduce manufacturing costs and use costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

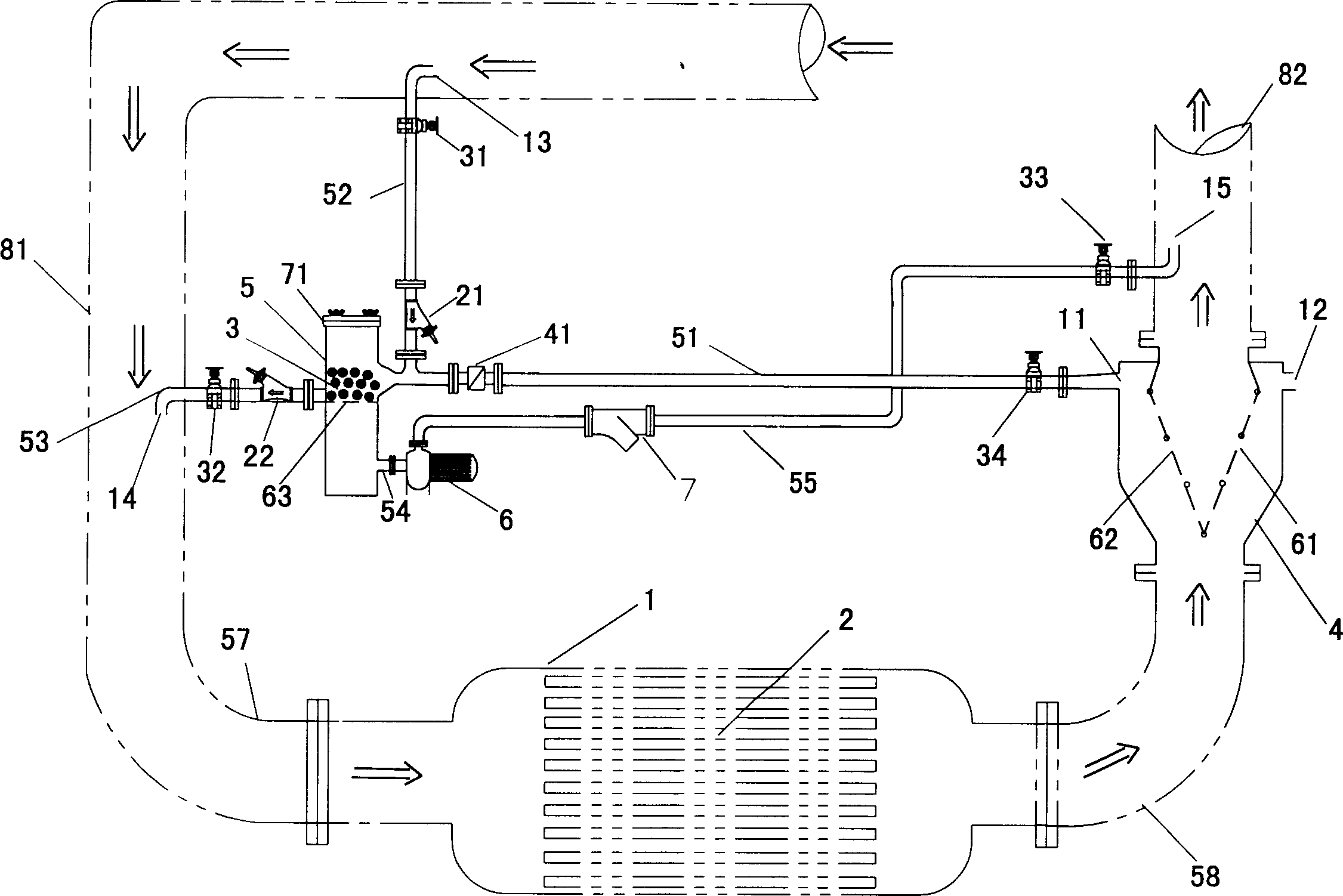

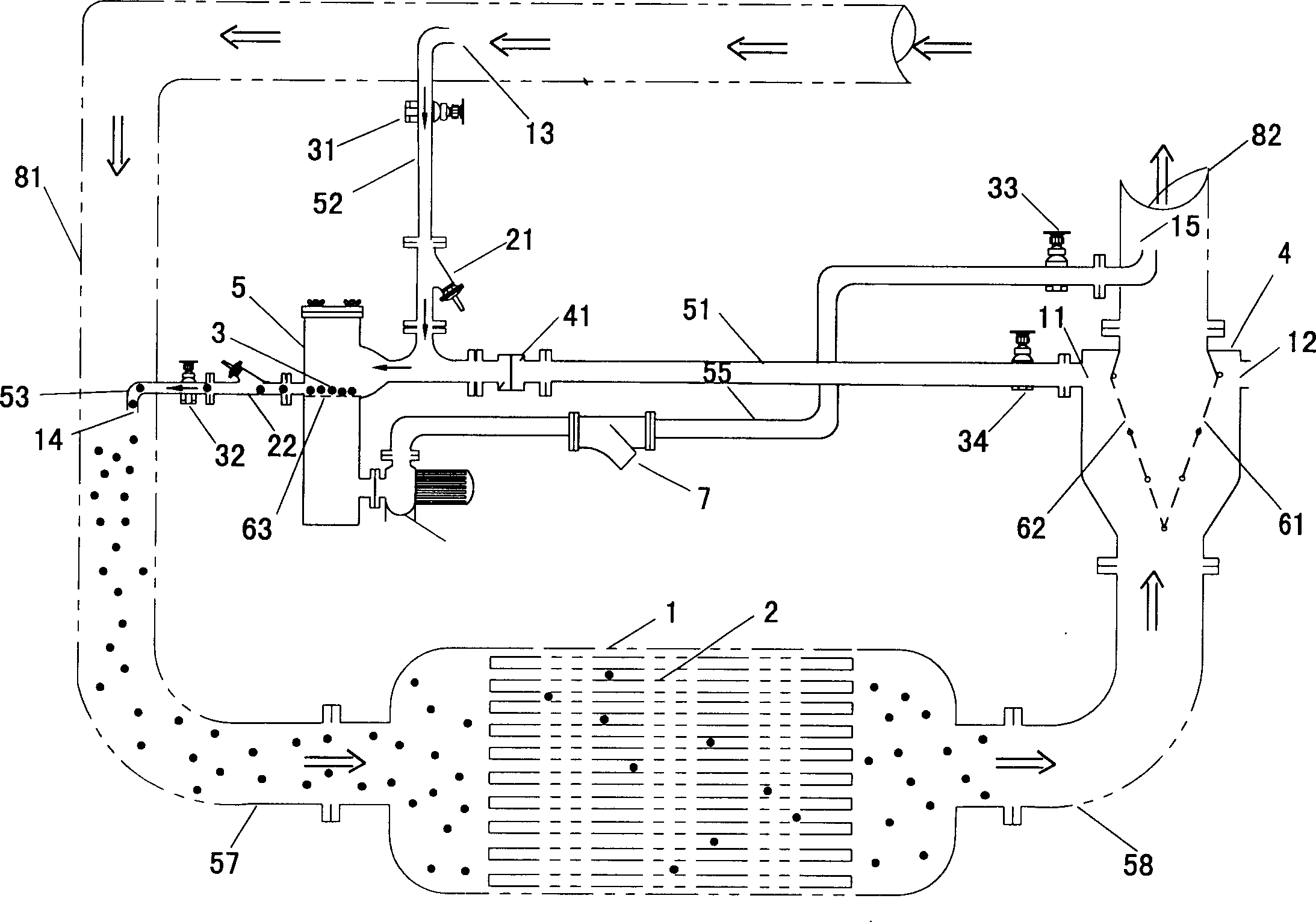

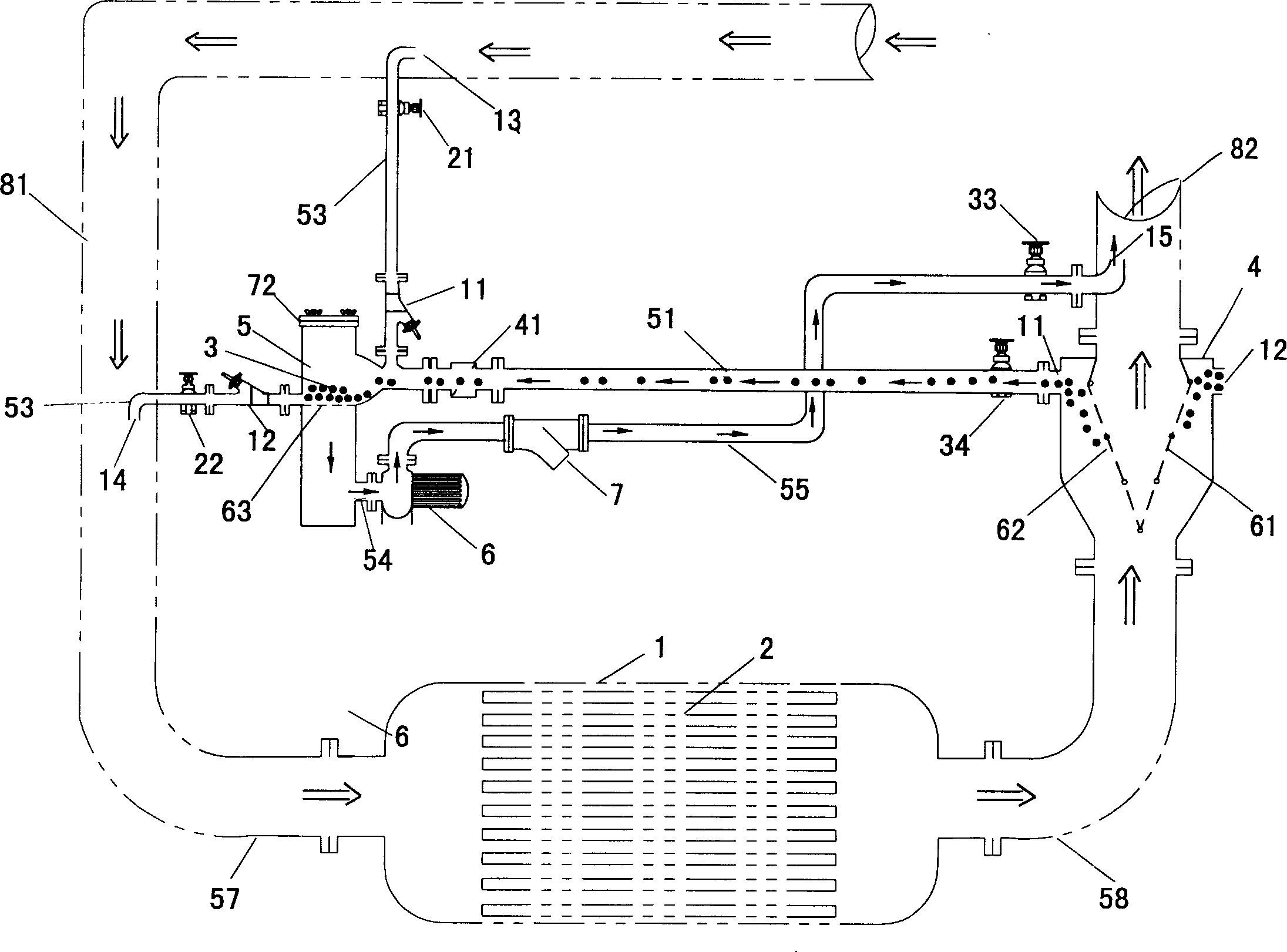

[0018] figure 1 The cleaning system shown comprises a condenser 1 comprising a conduit 2 in the form of a plurality of parallel spaced tubes through which a cooling fluid such as water circulates from a cooling water inlet 57 To the cooling water outlet pipe 58.

[0019] The cooling fluid comprises a number of cleaning pellets 3 forced to flow with the cooling fluid through the condensing tube 2 to prevent particle accumulation or deposits in the condenser tubes which tend to block or corrode the tubes. The balls 3 are made of a spongy material with a diameter slightly larger than that of the condenser tubes, so that they rub against the inner walls of the tubes, thereby keeping them clean. The technique of cleaning the tubes of condensers and other forms of heat exchangers with cleaning pellets is well known.

[0020] The ball returning controller 4 is arranged between the cooling water outlet pipe 58 and the downstream side 82 of the cooling water pipeline. Such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com