Impression mother plate with line pattern, method for forming same

A master and texture technology, which is applied in the field of embossed masters with texture patterns, can solve the problems of inability to copy patterns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] For other purposes and effects of the present invention, please refer to the embodiments shown in the accompanying drawings, which are described in detail as follows.

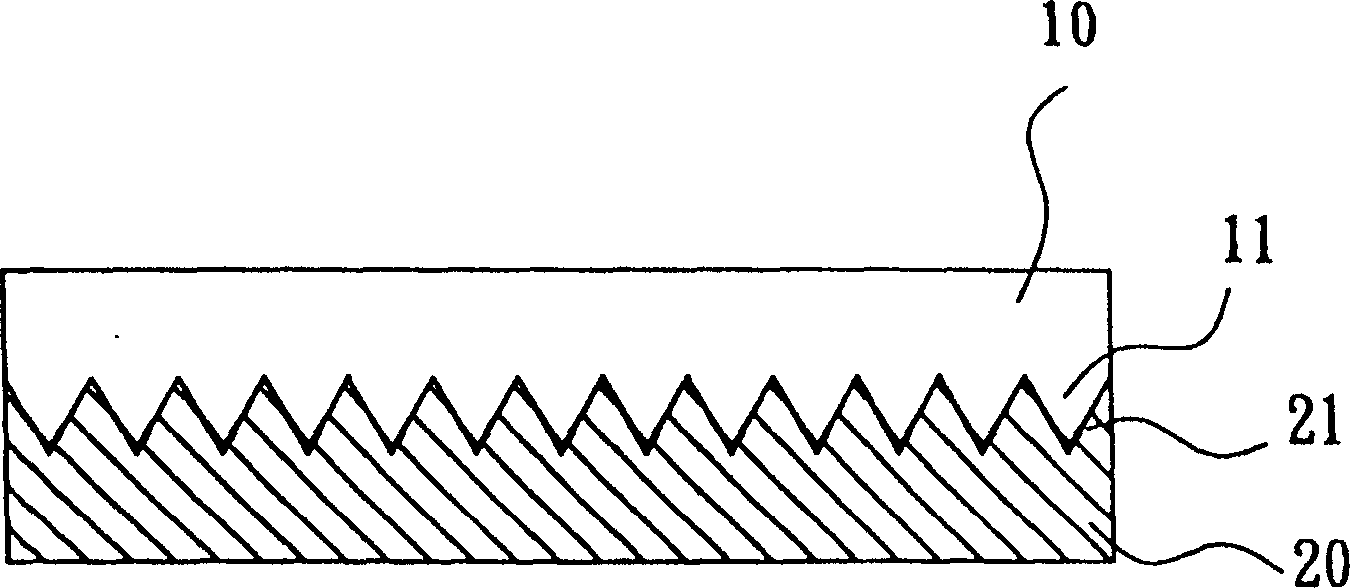

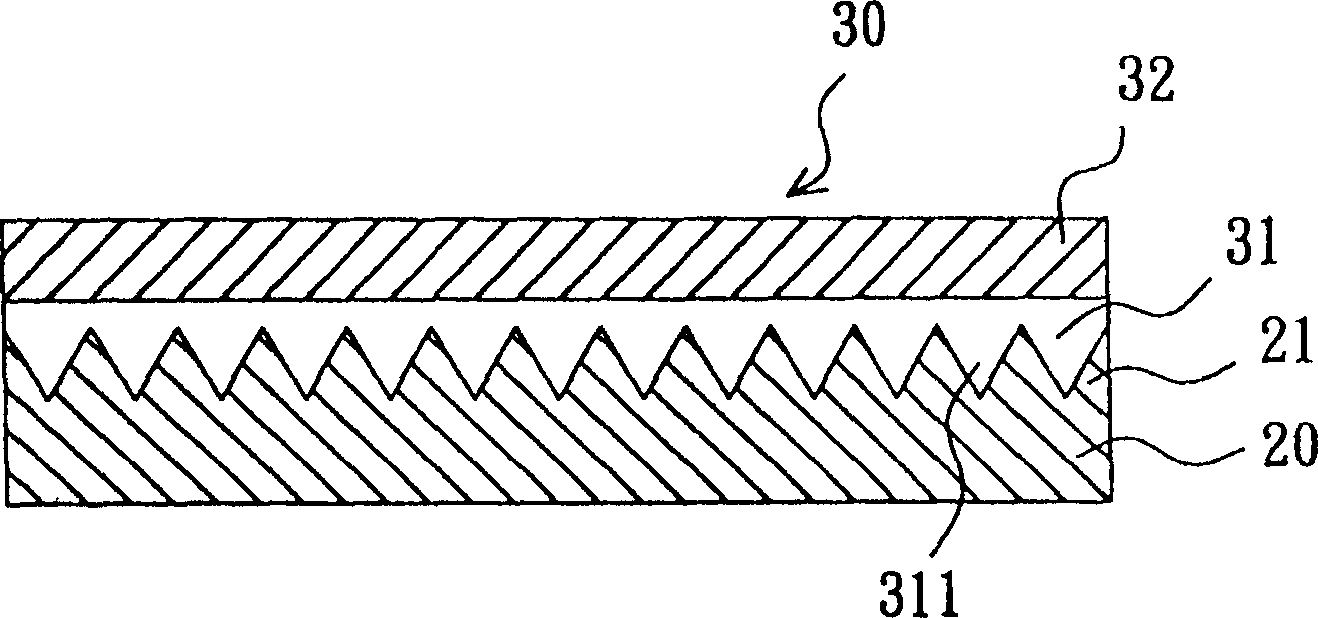

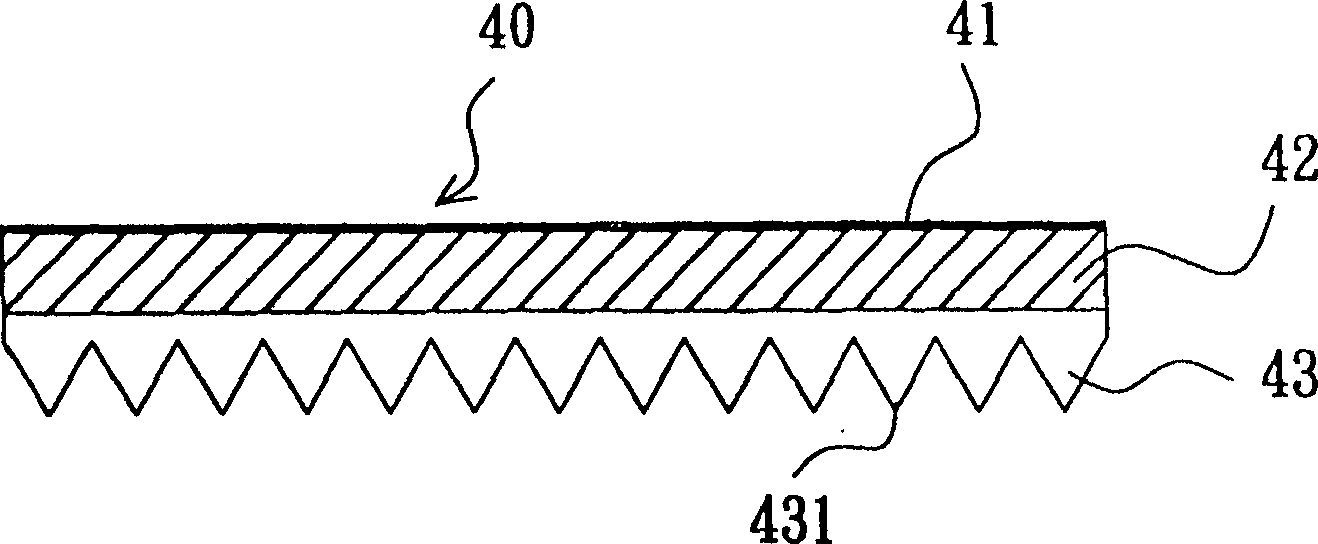

[0030] Please refer to Fig. 2 (A) shown, the manufacture method of master plate unit of the present invention is to utilize photosensitive type UV adhesive 31 to be coated on the master mold 20 surface of tool texture 21, and cover transparent plate 32 on UV adhesive 31, as It is made of PC or PVC material; make the UV glue 31 penetrate into the texture 21 completely to form the corresponding texture 311; irradiate UV light to make the UV glue 31 mature and harden, so that the UV glue 31 will be attached to the transparent plate 32; then make the UV glue 31 Separated from the master mold 20 , the texture 21 of the master mold 20 is completely copied on the UV glue 31 . Repeat this step several times to obtain several pieces of master units 30 with deep lines 311 .

[0031] As shown in the aforementioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com