Main control case of nanometer-particle microscope

A nanoparticle and microscope technology, applied in microscopes, optics, instruments, etc., can solve the problems of functional template interference, poor heat dissipation performance, and large space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

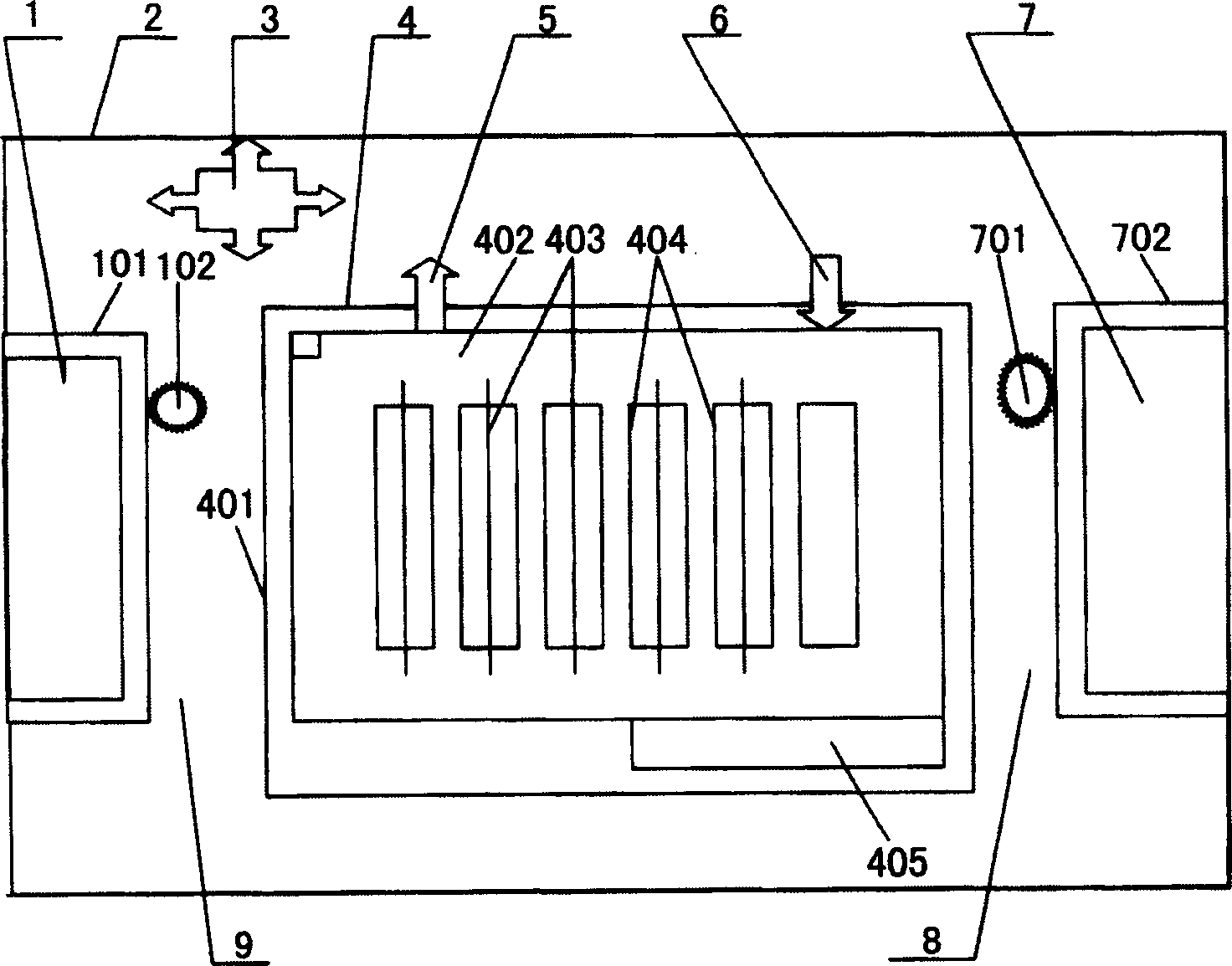

[0007] Further illustrate the structure of main control box of the present invention below with reference to accompanying drawing.

[0008] Such as figure 1 As shown, in the box body 2, a high-voltage amplification module 1, a heat dissipation and exhaust system 3, a main control module 4, and a high-voltage and low-voltage power supply system module 7 are placed independently of each other. The high-voltage amplification module 1 and the high-low voltage power supply system module 7 are placed on both sides of the box body 2, and the main control module 4 is placed in the middle of the two. There is a first cooling channel 9 between the high-voltage amplification module 1 and the main control module 4 . There is a second cooling channel 8 between the high and low voltage power supply system module 7 and the main control module 4 . The first cooling channel 9 and the second cooling channel 8 surround the main control module 4 and communicate with the cooling and exhaust syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com