Dry-process deep-etching silicon miero mechanical working method an glass substrate

A technology of silicon micromachines and glass substrates, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of lower processing yield, lower performance, and difficult control, etc., and achieve low manufacturing costs and finished products High efficiency, easy operation and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

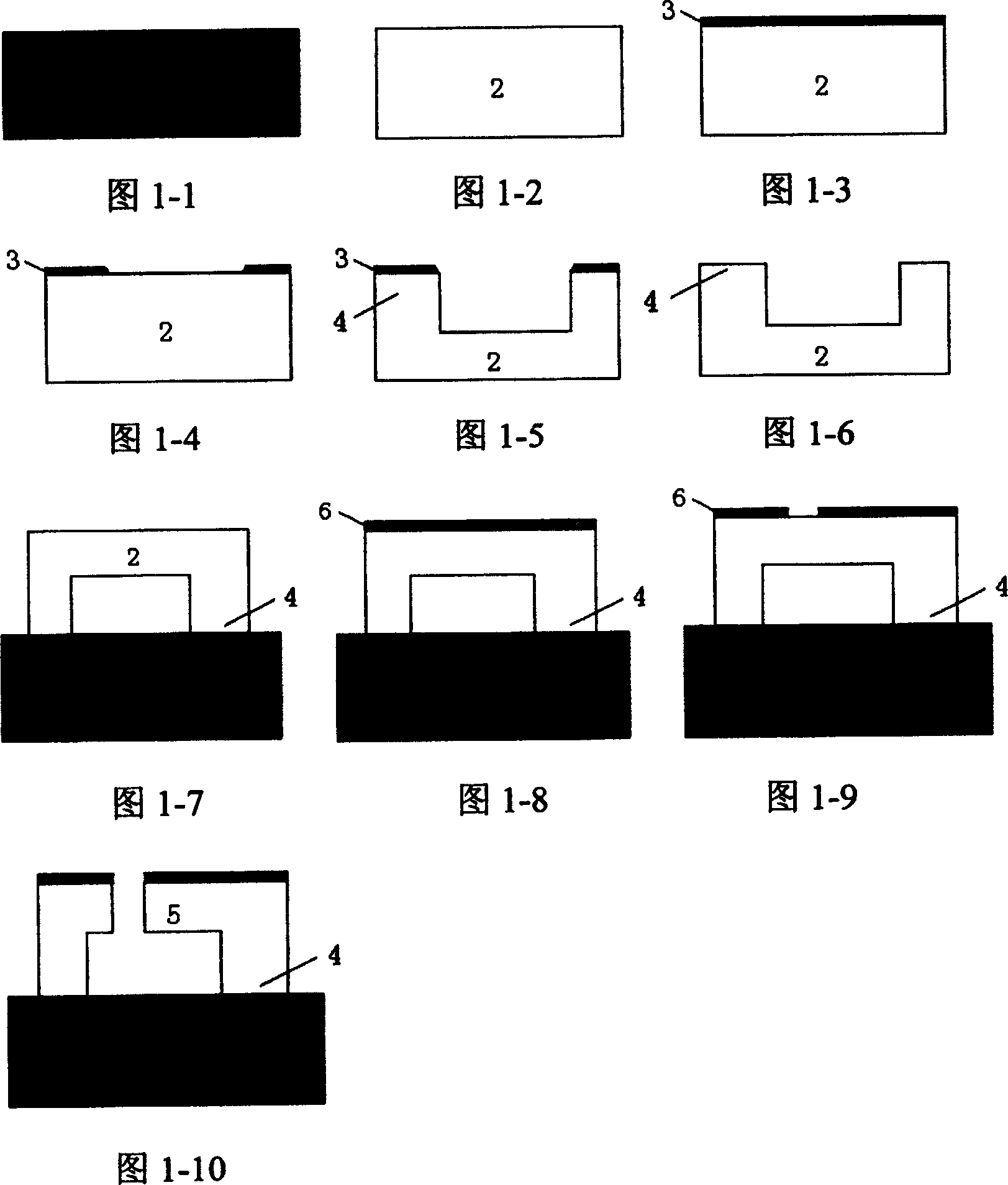

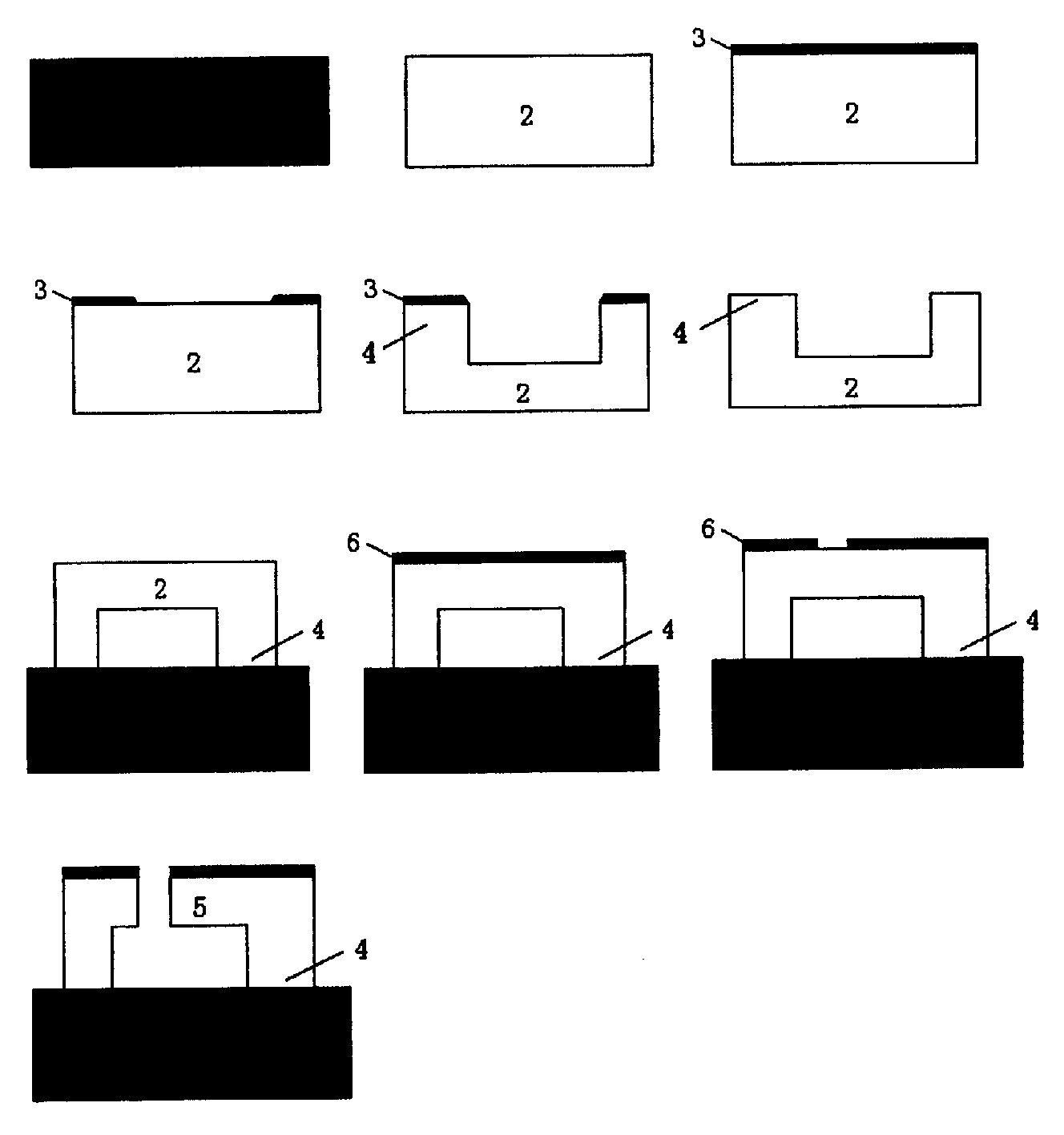

[0020] (1) Double-sided polishing heat-resistant 7740 glass sheet 1 on a commercially available general polishing machine, such as Picture 1-1 .

[0021] (2) double-sided polished single crystal silicon wafer 2 on a commercially available general polishing machine, the thickness of double-sided polished single crystal silicon wafer 2 is 280 μ m to 320 μ m, and the thickness of embodiment double-sided polished single crystal silicon wafer 2 is 300 μ m, such as figure 1 -2.

[0022] (3) A layer of positive AZ1450 photoresist 3 is coated on the double-sided polished single crystal silicon wafer 2, and the thickness of the coated photoresist 3 is 2 μm, such as figure 1 -3.

[0023] (4) Carry out lithography with a commercially available general-purpose lithography machine, and form a silicon-glass bonded bonding table 4 pattern window on one side of the double-sided polished single crystal silicon wafer 2, such as figure 1 -4.

[0024] (5) With the photoresist 3 as a mask, de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com