Operation control device and method of reciprocating motion type compressor

A technology of reciprocating motion and operation control, used in pump control, machine/engine, liquid variable capacity machinery, etc., can solve problems such as reducing reliability, piston wear, collision, etc., and achieve the effect of preventing noise and reducing runaway operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The functions and effects of the reciprocating compressor will be described in detail below with reference to the drawing of the operation control device and method of the reciprocating compressor.

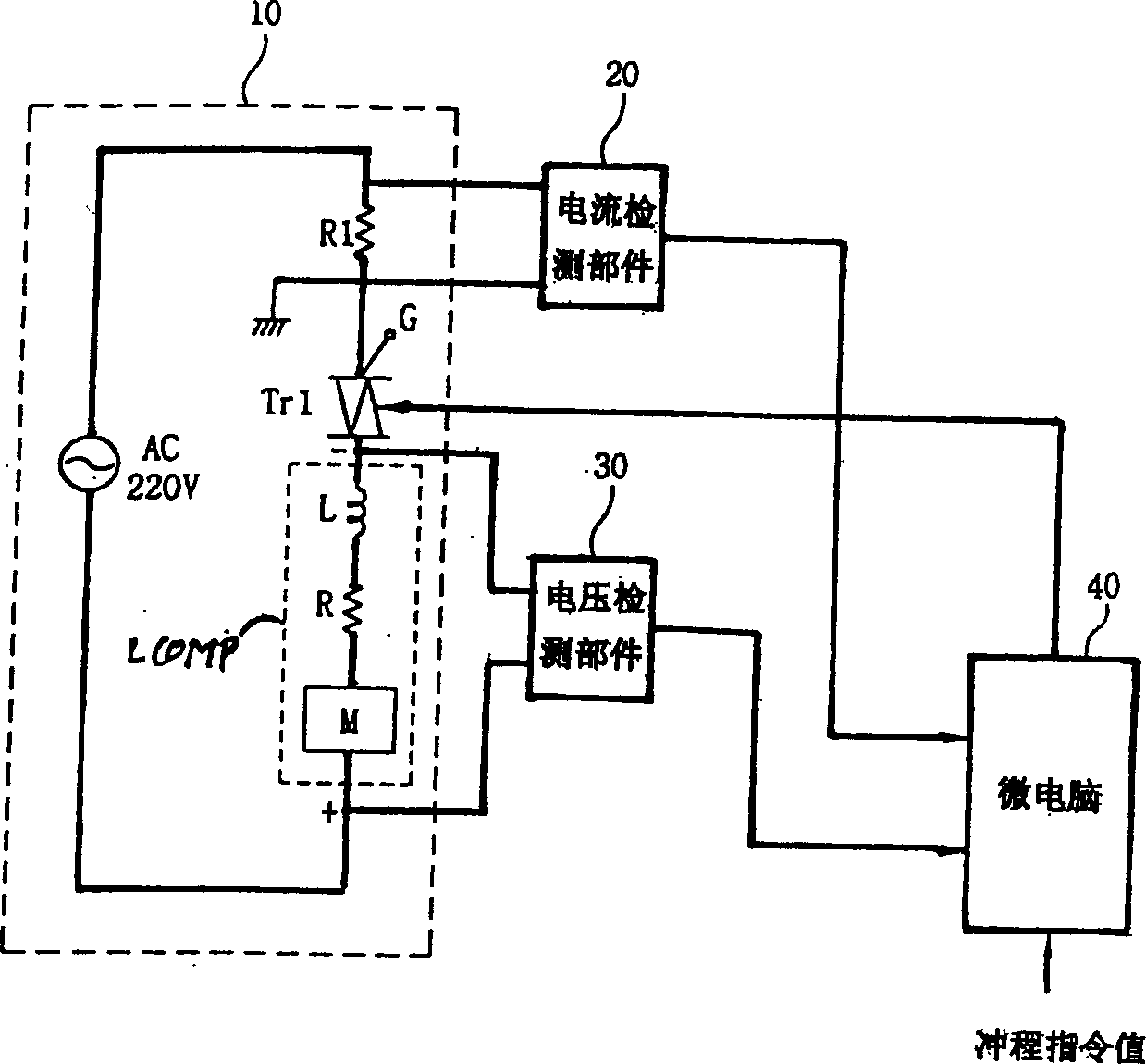

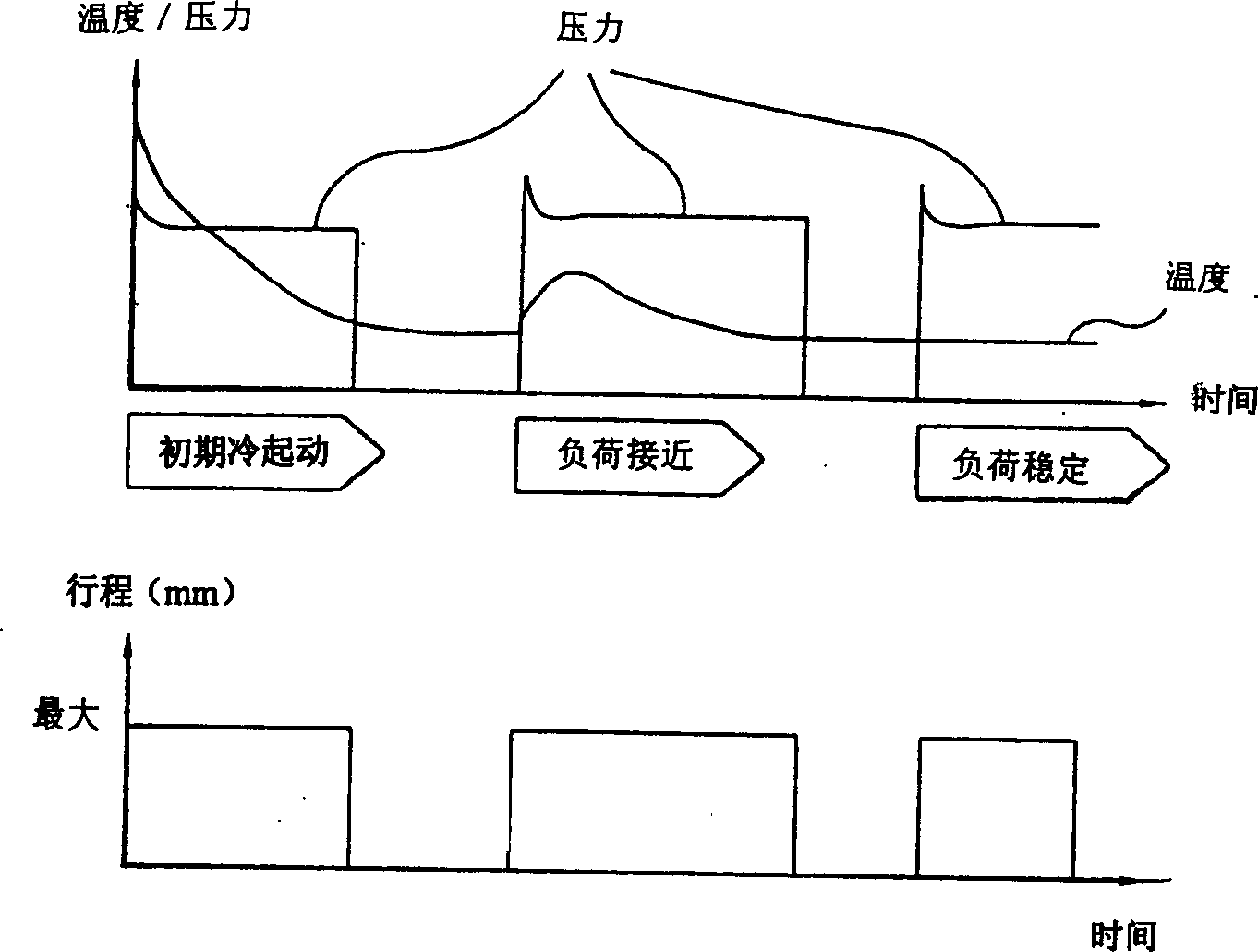

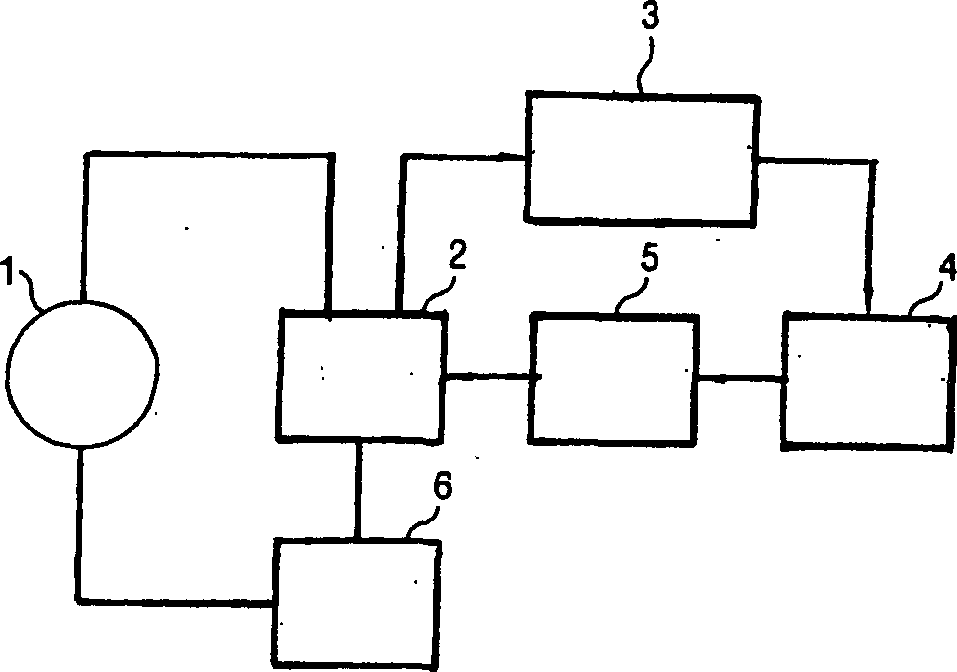

[0039] image 3 It is a functional block diagram of the operation control device of the reciprocating compressor. It consists of the following components: Power supply unit for driving the compressor and providing AC power 1: Load detection circuit box for detecting the electrical signal in the circuit as a load image 3 : The above load detection component circuit box image 3 Comparison circuit box for comparing the detected load with the rated load limit value and calculating the piston stroke Figure 4;According to the comparison circuit box Figure 4 The calculated piston stroke sets the stroke command value, and outputs the control circuit box of the transfer switch control signal issued by the stroke command value Figure 5 ; According to the control circuit box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com