Grinding block for processing organic nanometer powder

A nano-powder and grinding disc technology, which is applied in the fields of application, cocoa, and grain processing, can solve the problems of heat generation and poor wear resistance, and achieve the effect of overcoming easy heat generation, good wear resistance, and no heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

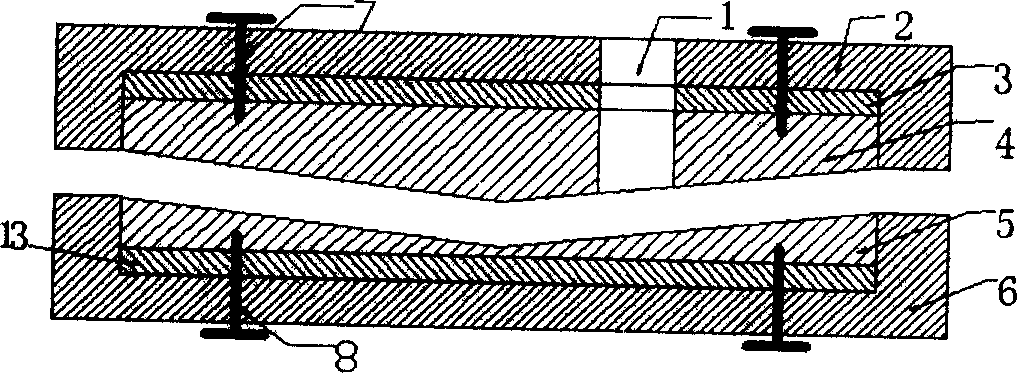

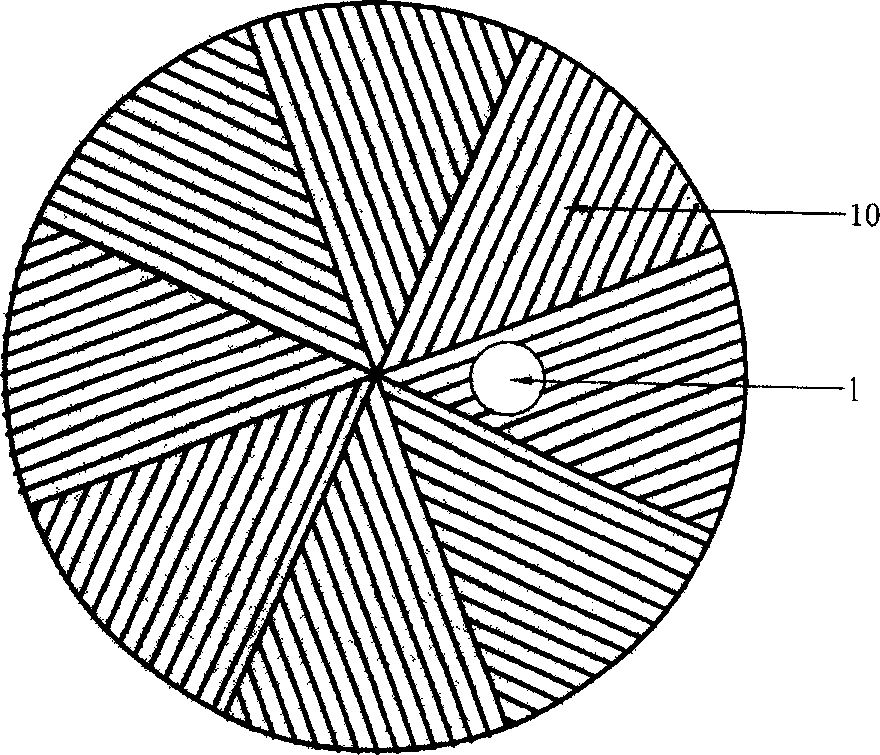

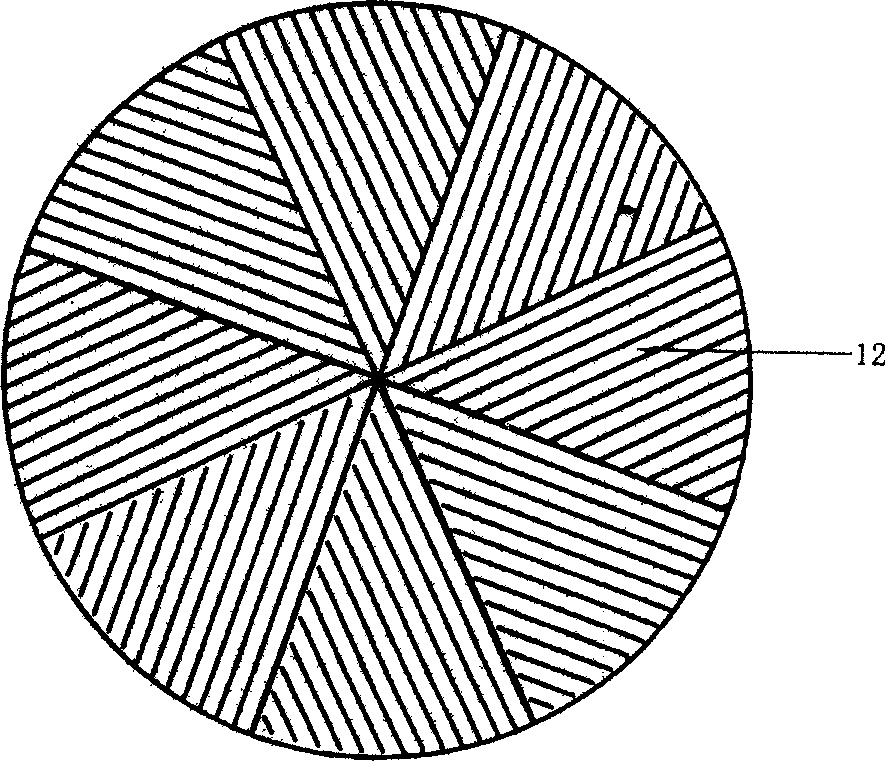

[0014] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 .

[0015] A grinding disc for processing organic nano-powder, the upper and lower grinding discs are respectively composed of upper and lower jackets 2, 6, upper and lower disc cores 4, 5, upper and lower rubber pads 3, 13, upper and lower jackets 2, 6, The upper and lower disc core frames are made of metal, the upper disc core 4 is in the shape of an outer cone, and the lower disc core 5 is in the shape of an inner cone, and the upper and lower disc cores 4, 5 can be matched with each other to form a running-in surface. The upper and lower disc cores are respectively composed of upper and lower disc core frames and 10 and 12 upper and lower ceramic teeth. The upper and lower disc core frames are divided into eight equal fan-shaped area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com