Brake assembly shoe tension detection assembly

A tension detection and brake technology, applied in the direction of tension measurement, brake type, mechanical equipment, etc., can solve the problems of cumbersome detection process, high cost, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

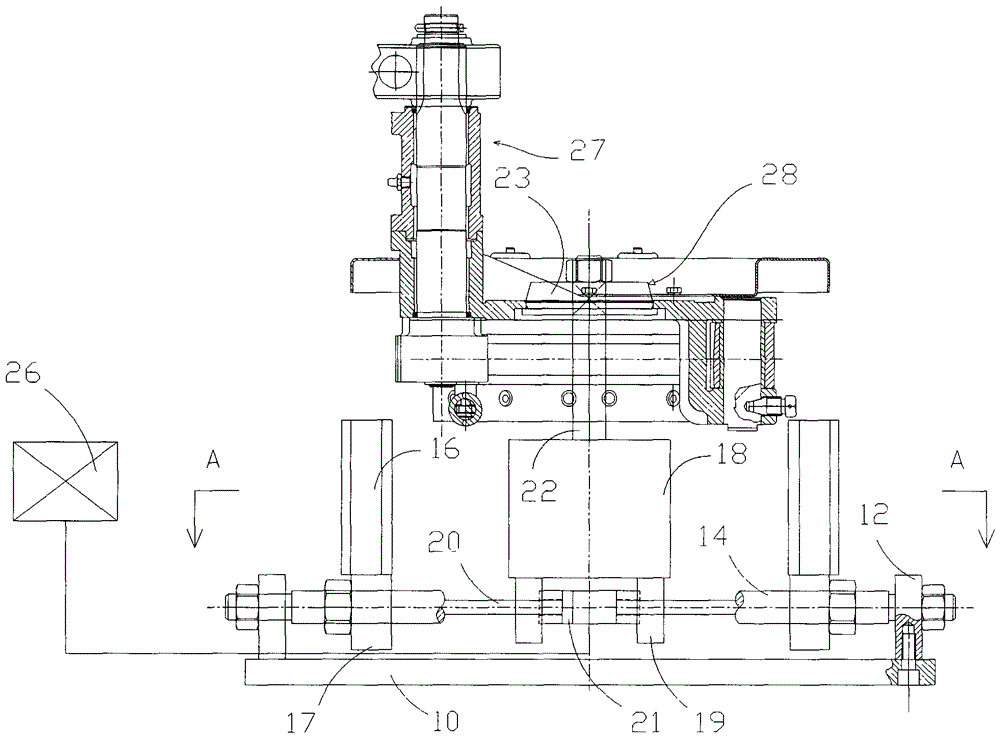

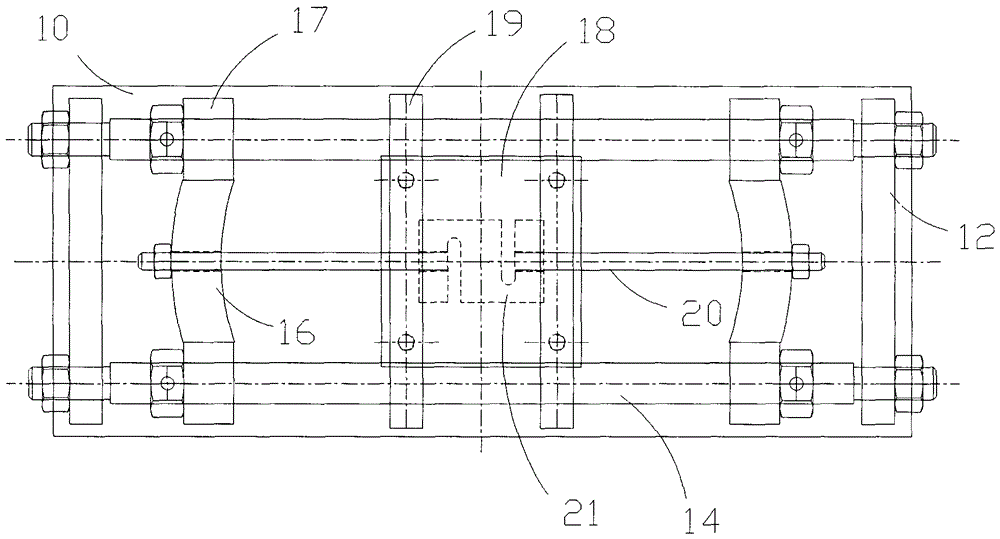

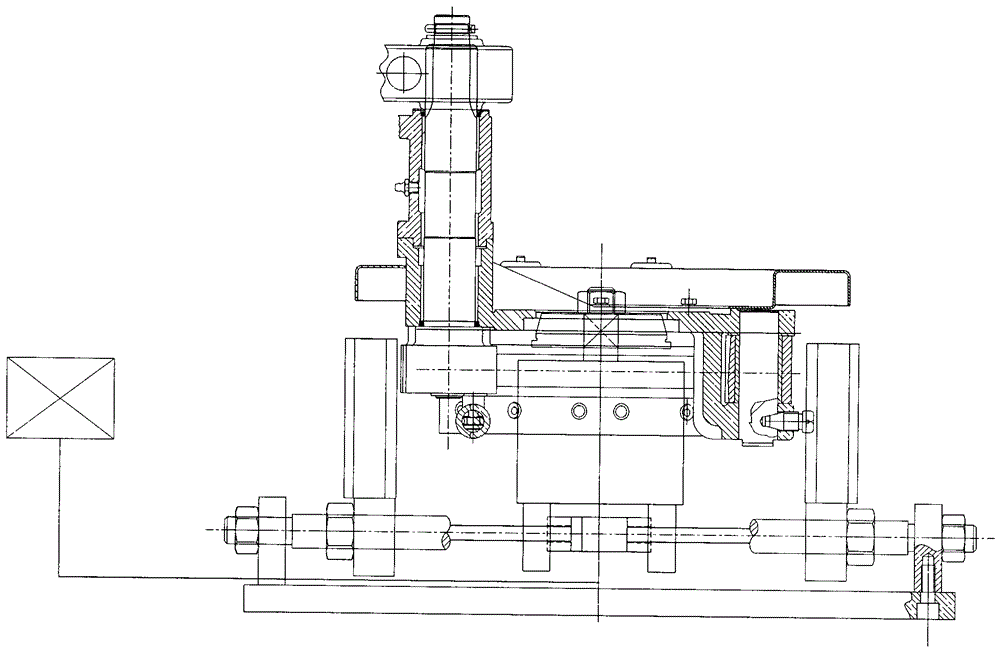

[0017] In order to further describe the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Figure 1-3 The shown brake assembly shoe tension detection assembly is arranged on the outside of the outer peripheral surface of the brake assembly shoe, and the detection assembly includes two sets of friction plate arc inspection tools arranged symmetrically along the center of the brake assembly shoe 16. The two sets of connecting rods 20 connected to the two sets of friction disc arc inspection tools 16 and directly below the shoe of the brake assembly, the tension sensor 21 arranged in the middle between the two sets of connecting rods 20, and the air chamber of the brake assembly 27 The inflated rear shoe expands to its outer peripheral surface and squeezes the friction disc arc inspection tool 16, transmits the tension through the connecting rod 20 and reads the tension data with the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com