Shutdown cooling pump vortex detection system

A shutdown cooling and coolant technology, applied to reactors, nuclear reactor monitoring, greenhouse gas reduction, etc., can solve impossible problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Detailed description of the preferred embodiment

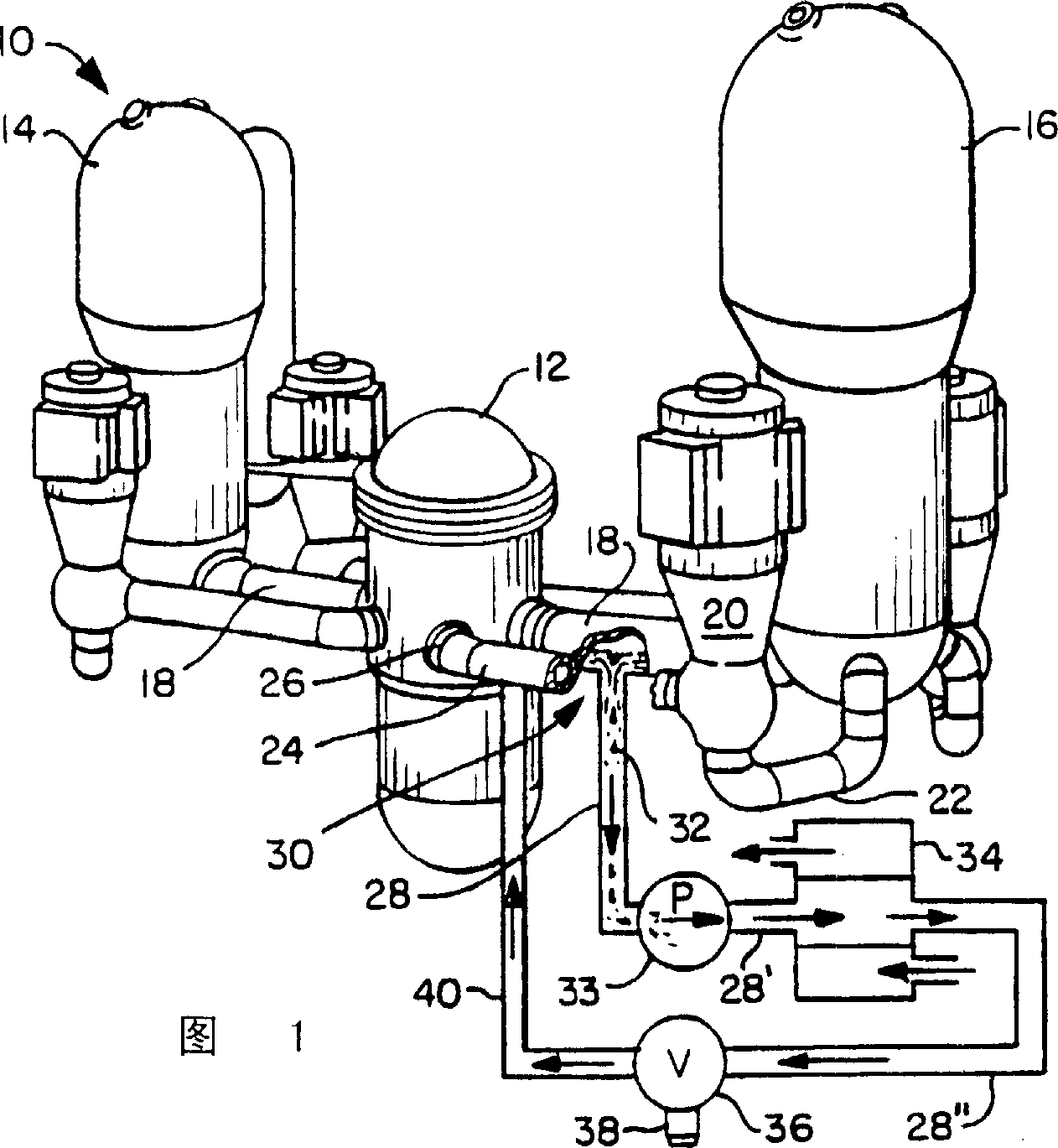

[0024] Shown in Fig. 1 is to have added a nuclear power plant of the present invention. Reference numeral 10 generally designates a nuclear power plant of the pressurized water reactor type in which water is continuously conveyed through a closed circulation loop between the reactor 12 and each of the two steam generators 14 and 16, respectively.

[0025] Water coolant from reactor 12 flows through main pipe or heat pipe section 18 to steam generators 14 and 16, with similar piping for each heat exchanger.

[0026] For purposes of illustration, with respect to steam generator 16 , cooling system circulation pump 20 circulates water that has been cooled in the steam generator through suction line section 22 and back to reactor 12 via cooling line section 24 and inlet 26 .

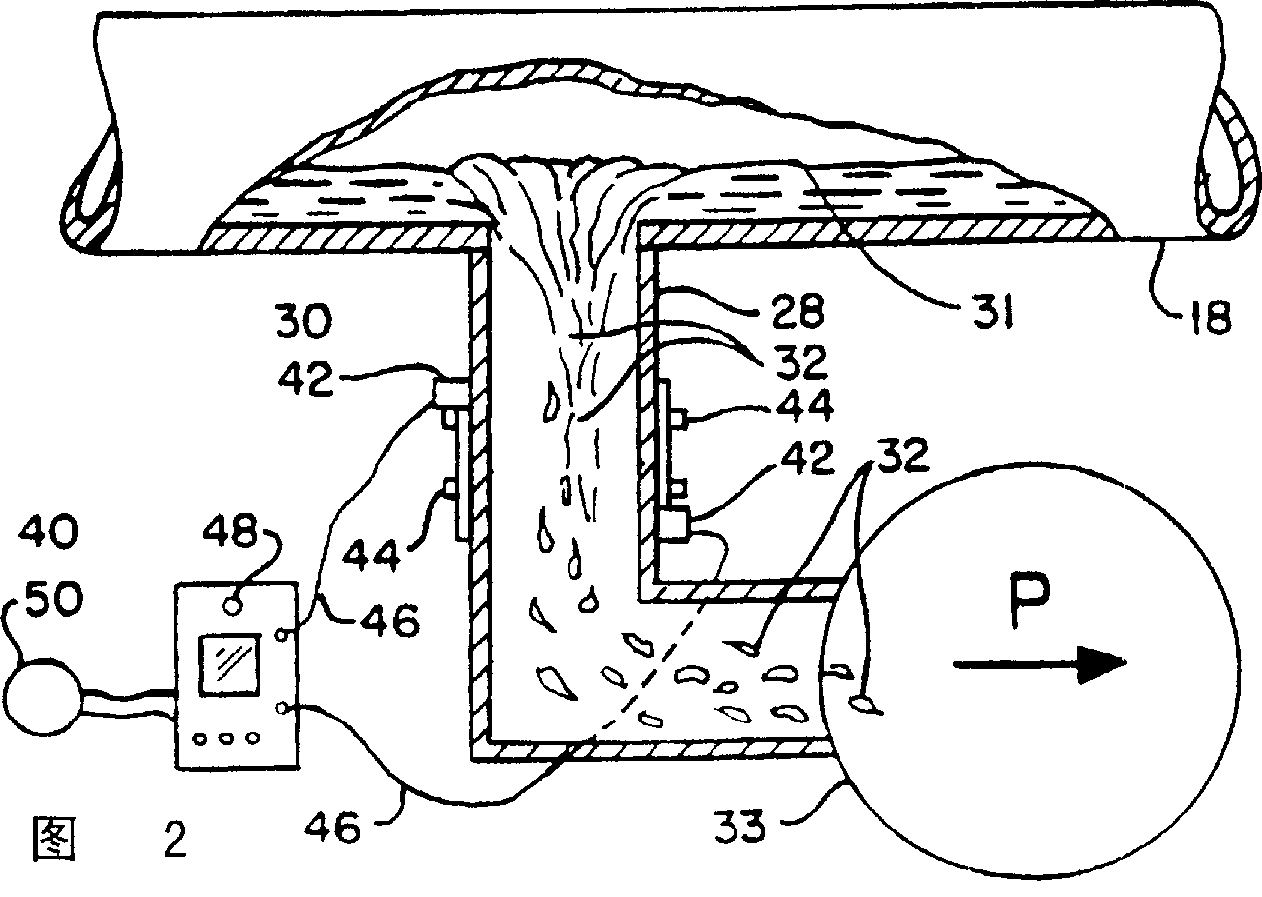

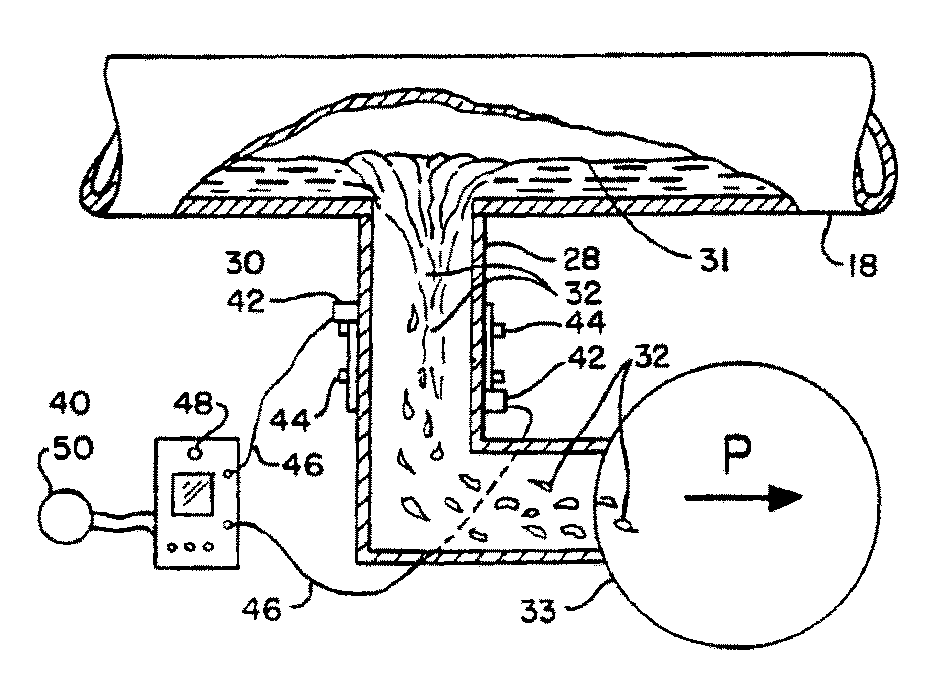

[0027] The shutdown cooling system drain pipe 28 intersects the lower region of the substantially horizontal main or heat pipe section 18 . In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com