Method for preparing plastic decorative plates

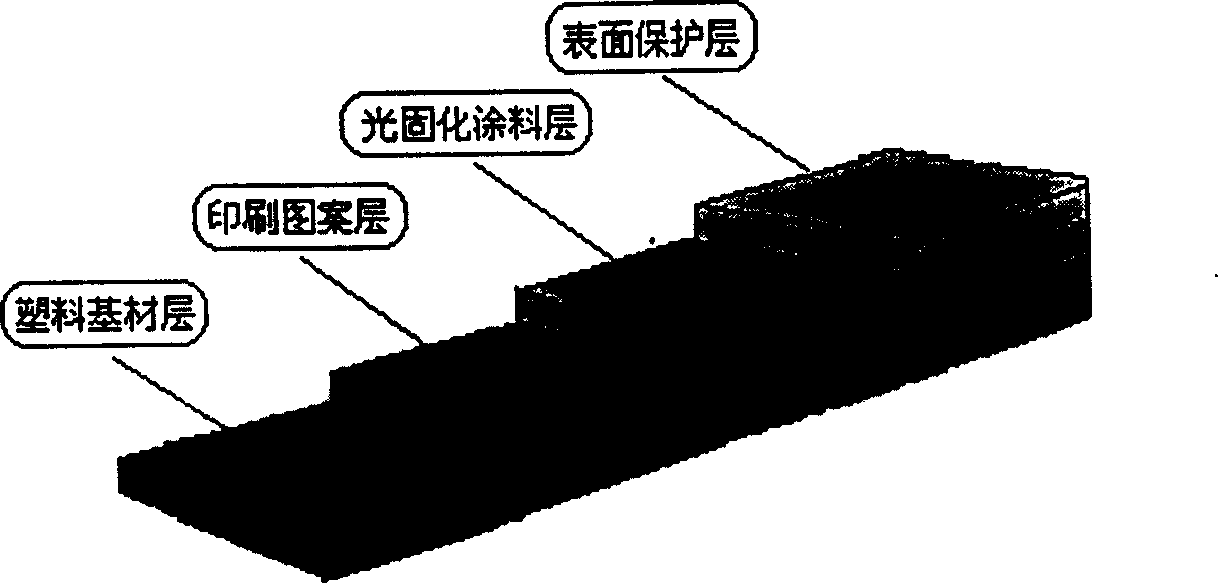

A technology of plastic boards and decorative boards, applied in building materials, coatings, etc., can solve the problems of high cost and unsatisfactory surface effects of film-coated metal decorative boards, and achieve good appearance effects, small production sites, and paint films plumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

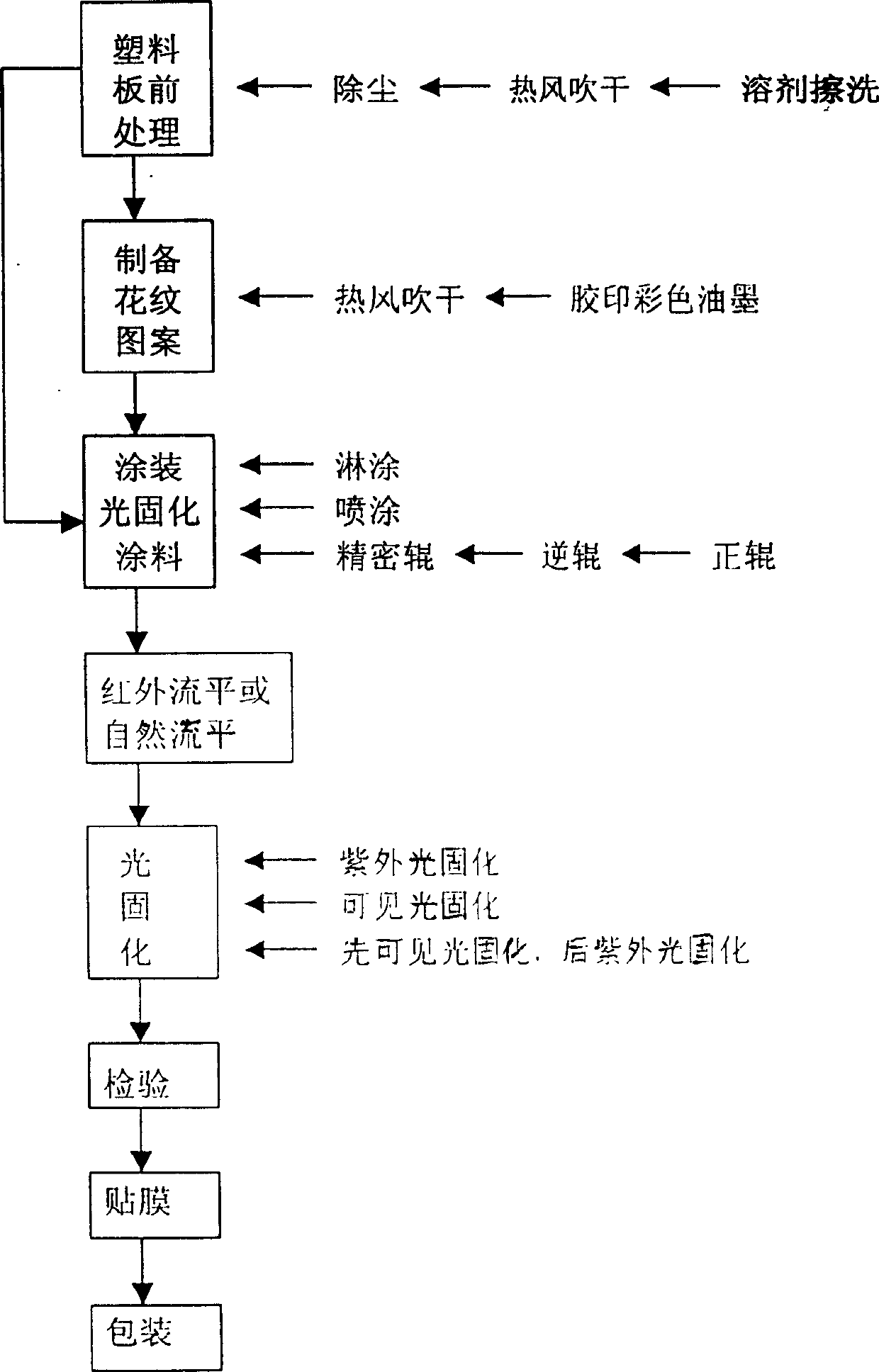

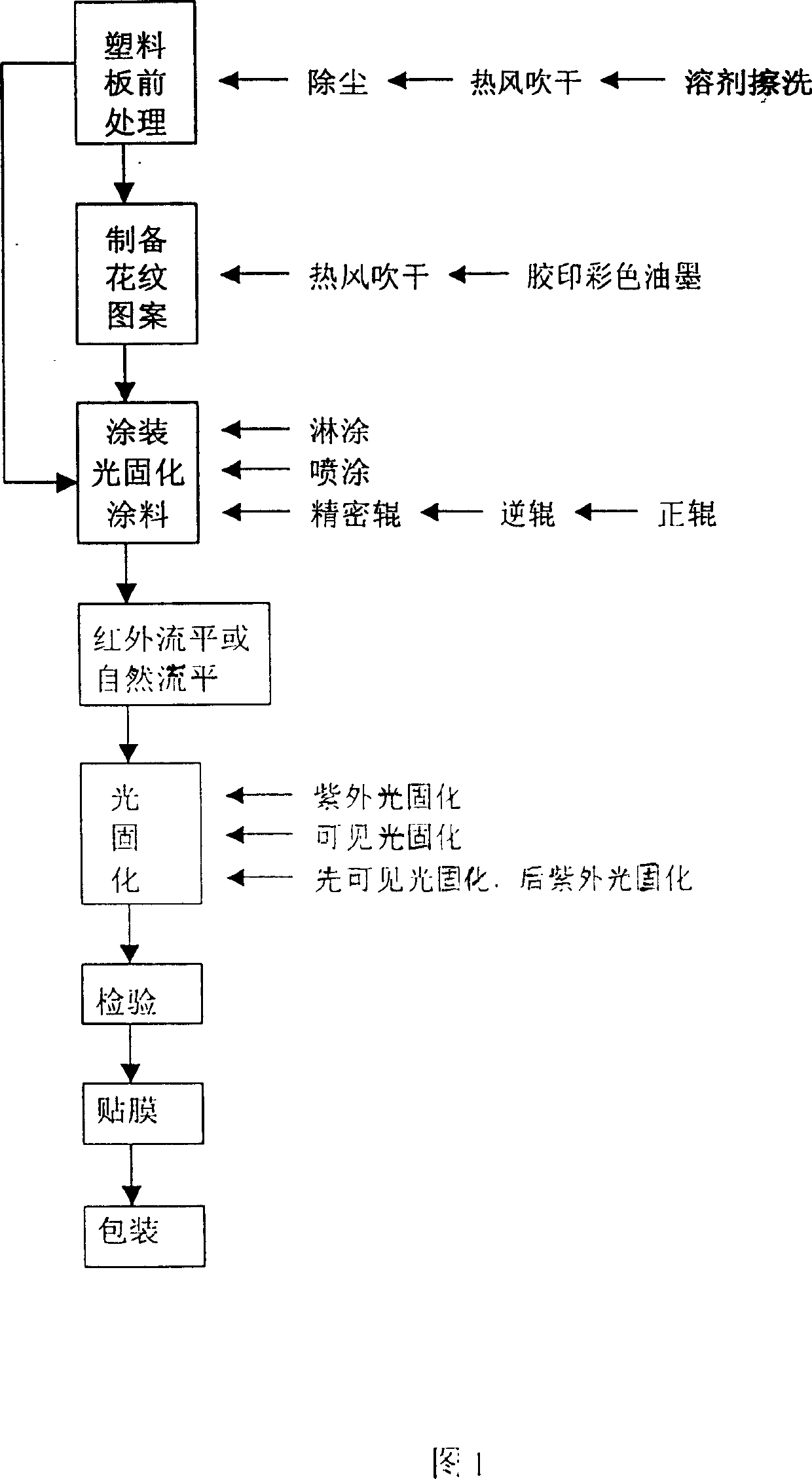

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Preparation of plastic decorative board by curtain coating light-curing varnish

[0038] Plastic substrate: the surface layer is a single color (such as pure white, dark blue) or a simple color stripe pattern formed by a mixed extrusion process

[0039] First use an electrostatic induction rod to eliminate the static electricity on the surface of the plastic board, then use a dust removal device to remove the dust on the surface of the plastic board, and then use ethanol to wipe off the oil on the surface of the plastic board. The surface-treated plastic plate is sprayed with light-cured varnish on the flow coater through the belt conveyor. The temperature of the feed tank of the flow coater is 55°C, the transmission speed is 80 m / min, and the thickness of the light-cured coating on the surface of the plastic plate is 60-80um. Leveling under infrared at a temperature of 50°C for 20 seconds, entering a light curing machine equipped with three 5kw ultraviole...

Embodiment 2

[0040] Embodiment 2: Preparation of plastic decorative board by curtain coating light-cured metal flash coating

[0041] Plastic substrate: the surface layer is a single color (such as pure white, light blue) or a simple color stripe pattern formed by a mixed extrusion process

[0042] First use a static induction rod to eliminate the static electricity on the surface of the plastic board, then use a dust removal device to remove the dust on the surface of the plastic board, and then use isopropanol to wipe off the oil on the surface of the plastic board. The surface-treated plastic plate enters the flow coating machine through a belt conveyor, and is flow-coated with a light-curing metal flash coating mixed with 0.1wt% aluminum powder in the light-curing varnish. The temperature of the feeding tank of the flow coating machine is 50 ° C, and the transmission speed is 80 m / min. The thickness of the light-cured coating on the surface of the plastic plate is 60-80um. Leveling un...

Embodiment 3

[0043] Example 3: Preparation of printed plastic decorative boards by curtain coating with photocurable varnish

[0044] Plastic substrate: pure white plastic board

[0045]First use a static induction rod to eliminate the static electricity on the surface of the plastic board, then use a dust removal device to remove the dust on the surface of the plastic board, and then use isopropanol to wipe off the oil on the surface of the plastic board. Monochrome or color patterns are printed on plastic plates by gravure printing. The ink used for printing patterns is self-drying solvent-based ink, and the printed plastic plates are dried by hot air. The plastic plate printed with patterns is sprayed with light-curing varnish on the flow coating machine through the belt conveyor. The temperature of the feeding tank of the flow coating machine is 50°C, the transmission speed is 90 m / min, and the thickness of the light-curing coating on the surface of the plastic plate is 60-80um. Level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com