Plastic spool cutter

A pipe cutting machine, plastic wire technology, applied in metal processing, etc., can solve the problems of high energy consumption, uneven cutting section, high noise, etc., to achieve the effect of reducing cutting chips, reducing motor drive, and smooth cutting section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

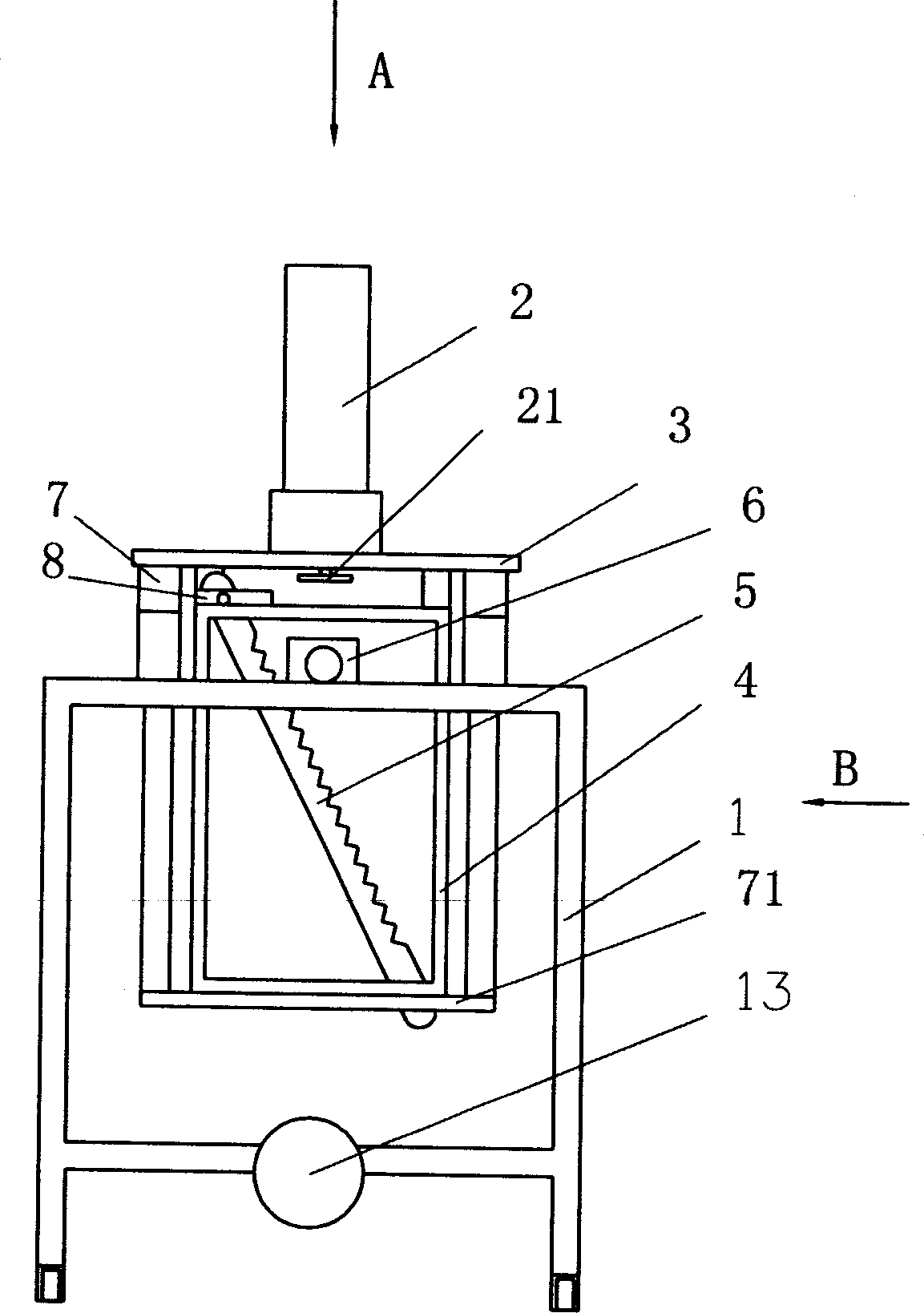

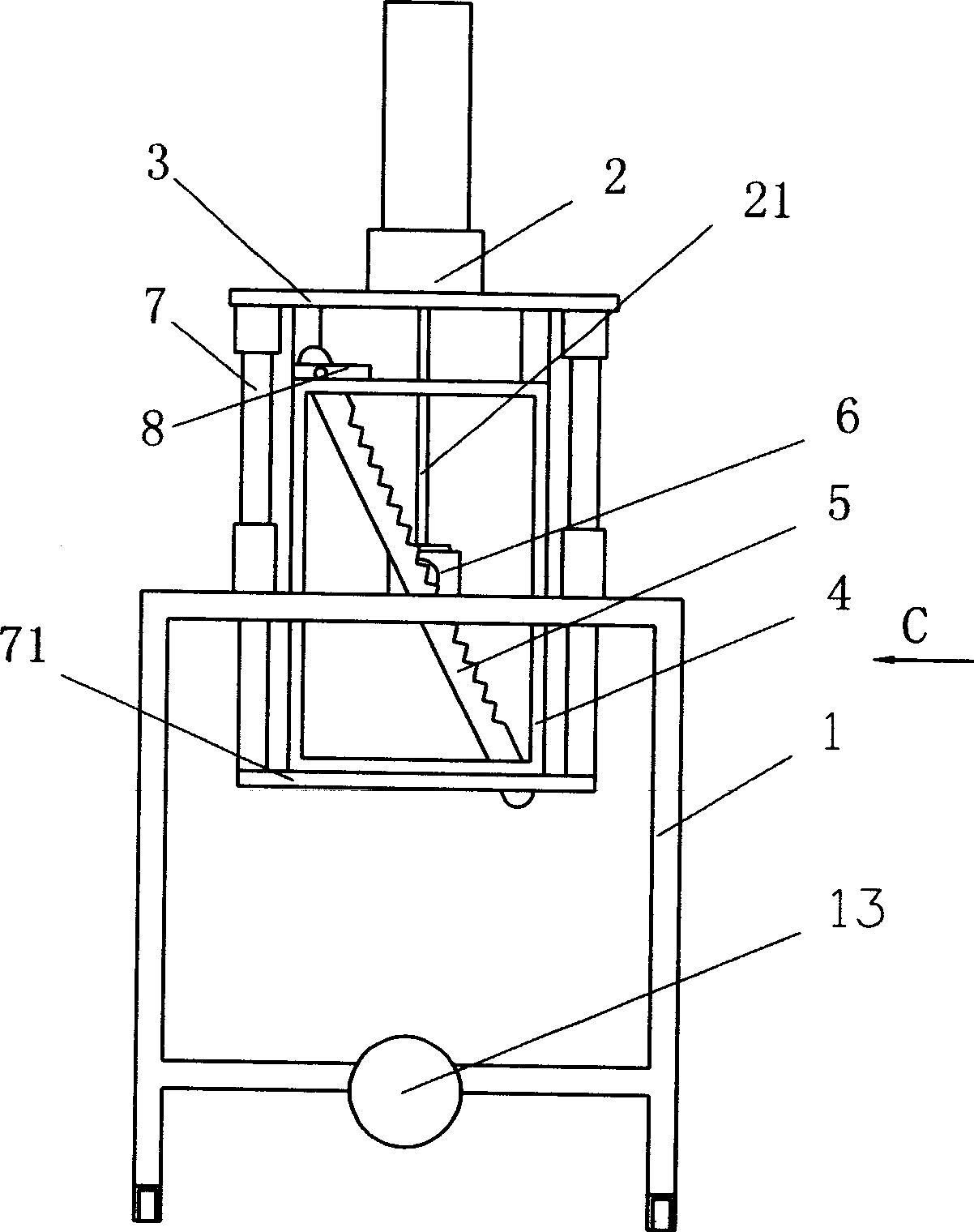

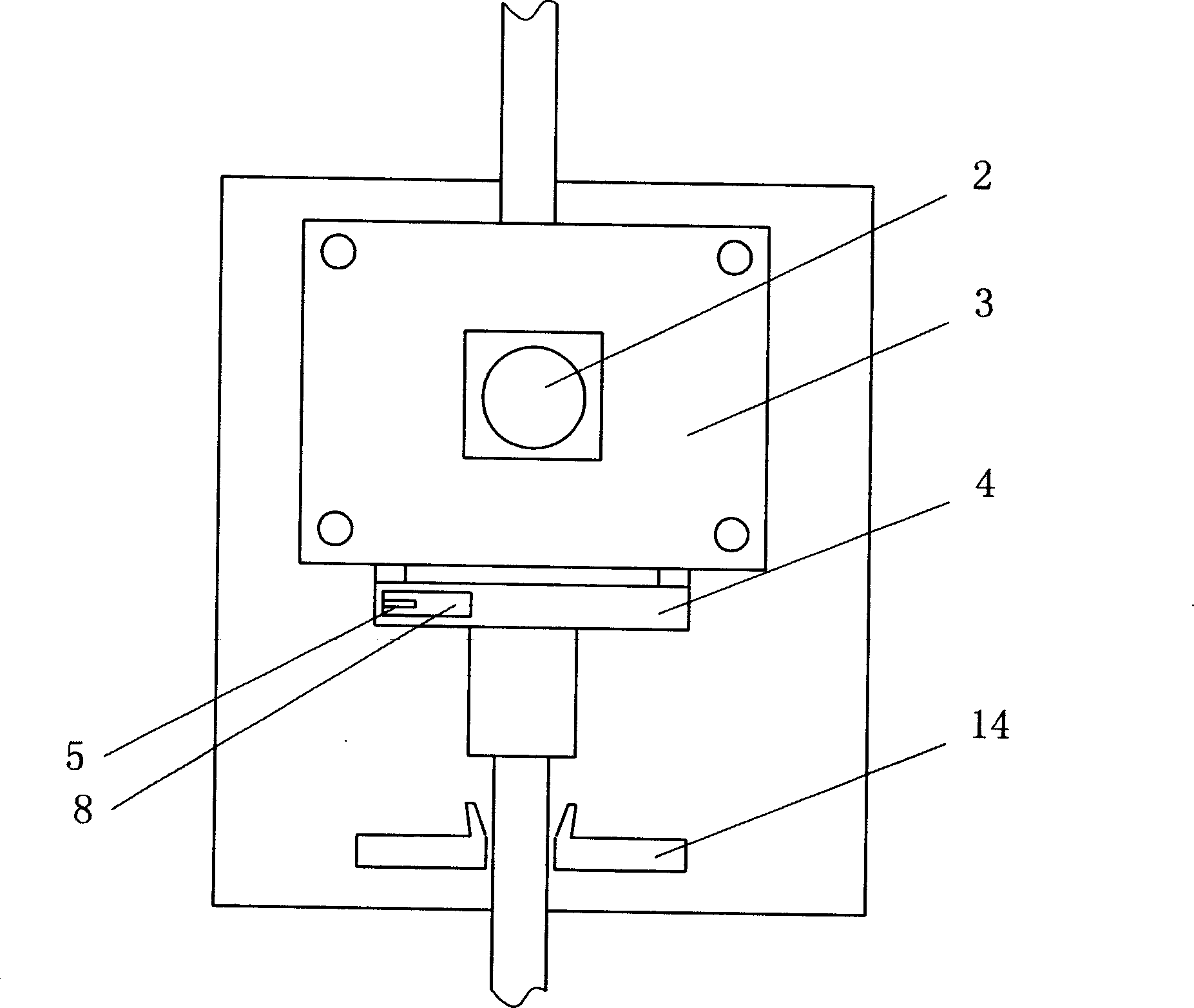

[0013] refer to figure 1 , figure 2 , image 3 , a kind of plastic wire pipe cutting machine of the present invention, it comprises frame 1, is installed on frame 1 and is driven by cylinder 2 elevating platform 3, below elevating platform 3 is fixedly connected with vertical knife rest 4, vertical knife rest 4 A cutting blade 5 is fixedly installed obliquely on the upper side, and a wire tube positioning and pressing block 6 is installed below the lifting platform 3. The movement track of the cutting blade 5 passes through the outlet of the wire tube positioning pressing block 6, and the lifting platform Four end angles of 3 are respectively equipped with telescopic positioning rod 7, and telescopic positioning rod 7 not only supports lifting platform 3 above the frame 1, but also makes lifting platform 3 more stable when rising or falling.

[0014] The working principle of the present invention is: the plastic wire tube enters the positioning and pressing block 6 on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com