Terrazzo made from siliconized crystal and fabricating technique thereof

A technology of terrazzo and crystal, which is applied in the field of crystal silicon-infiltrated terrazzo and its production technology, which can solve the problems of easy aging, labor-intensive consumption, and easy wear and tear, and achieve the effects of bright and beautiful surface, reduced maintenance cost, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

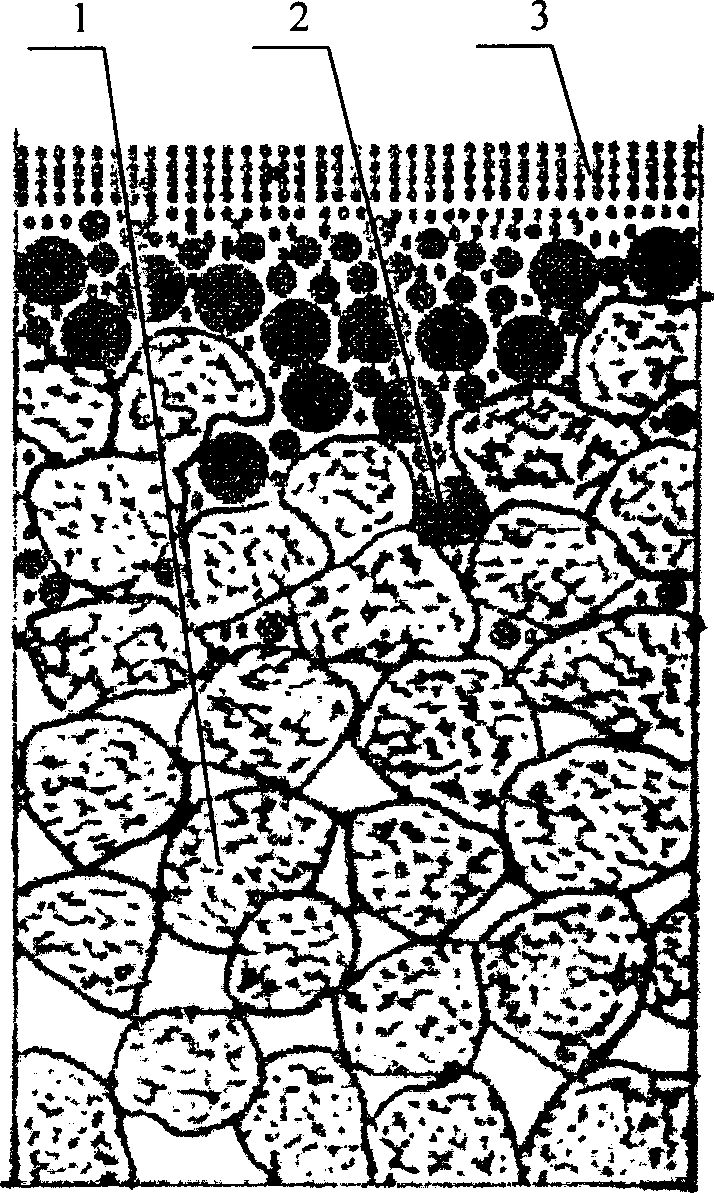

[0022] From figure 1 It can be seen that the organizational structure of the crystal siliconized terrazzo of the present invention has a terrazzo base layer 1 , a crystal siliconized layer 2 and a silicon dioxide surface layer 3 . In the formation process of the crystal siliconizing layer and the silicon dioxide surface layer, crystal siliconizing agent, hardening agent, and lightening agent are used. In the present embodiment, the crystal siliconizing agent consists of 15% polysiloxane, 15% di Oxygen-modified fluororesin and 70% acetone are mixed; hardening agent is made by mixing 20% magnesium fluorosilicate, 18% metal wax, 2% pigment, 30% water, and 30% acetone; The brightening agent is made by mixing 15% cerium oxide, 10% boron carbide fine powder, 20% wax, 25% water and 30% acetone.

[0023] The production process of the present embodiment crystal silicon infiltrated terrazzo is:

[0024] 1. Pouring the terrazzo foundation to form the terrazzo base;

[0025] Second, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com