Sidestream fourdrinier papermaking machine

A paper machine, flow length technology, applied in the field of side flow fourdrinier paper machine, can solve the problem of excessive shear force and achieve good evenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

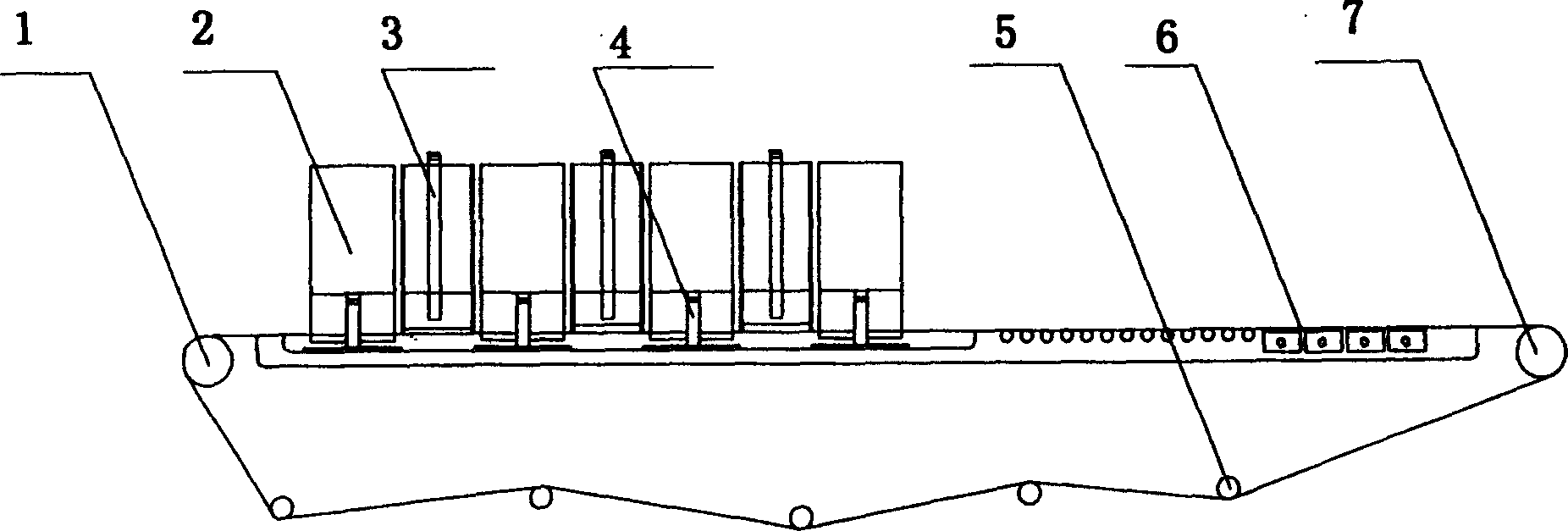

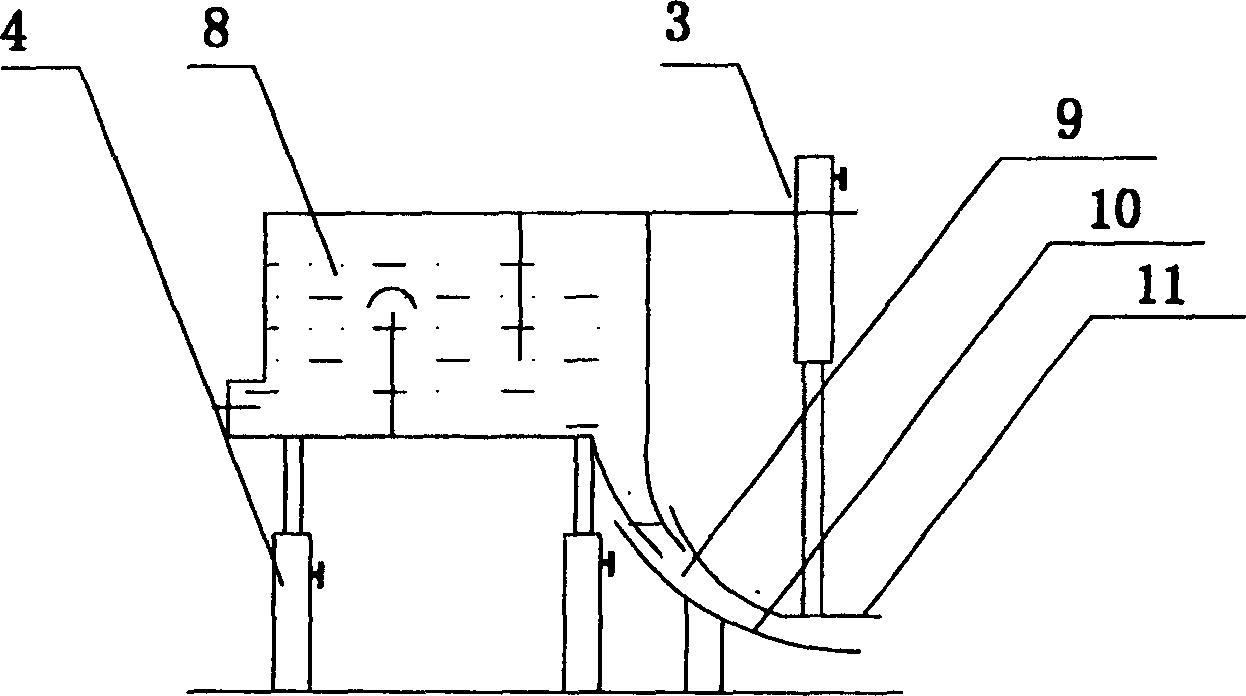

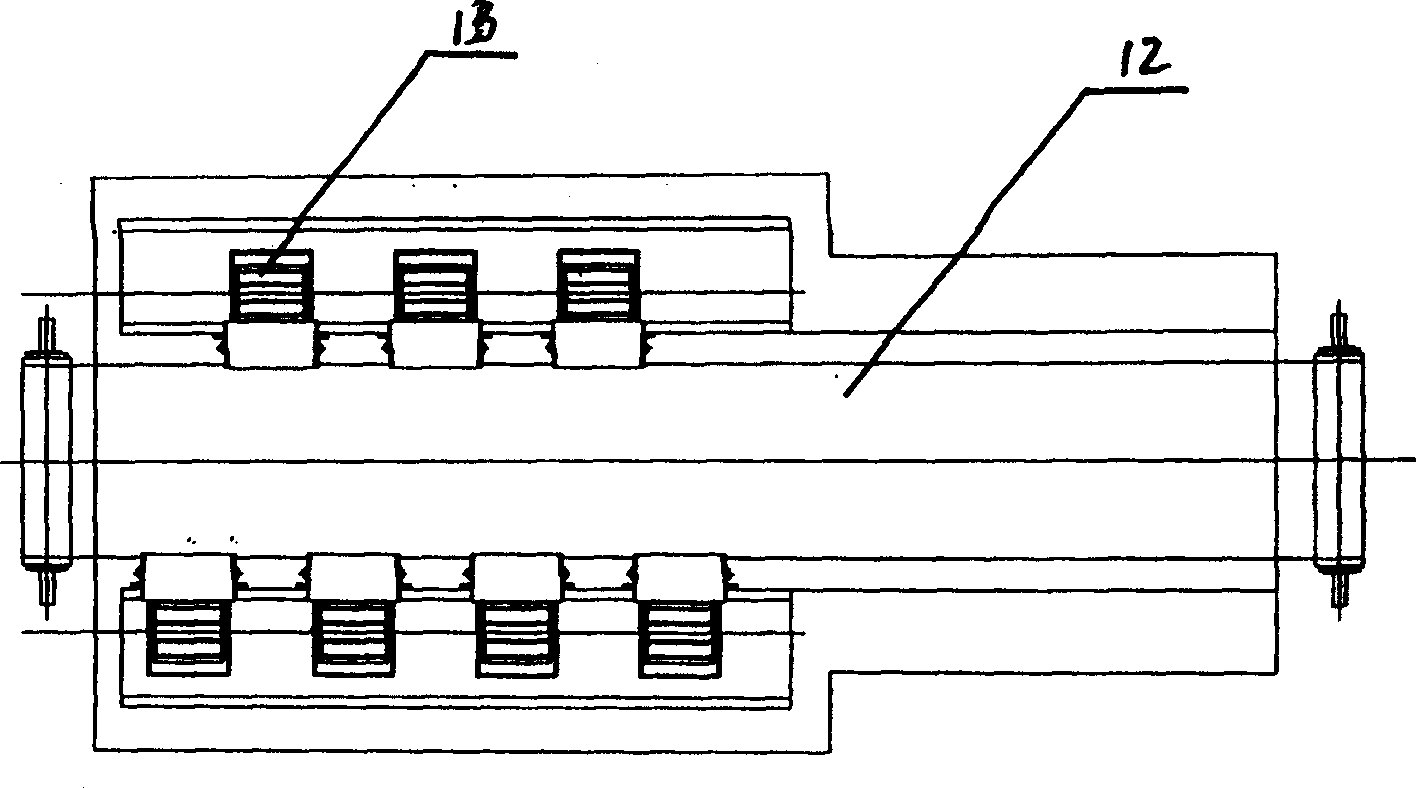

[0010] Embodiment: The side flow fourdrinier paper machine of this embodiment includes seven pulp distributors 2, one fourdrinier wire 6, several guide rollers 5, one return roller 7 and table roller 1. Seven box-type pulp distributors The device 2 is alternately distributed above the two sides of the Fourdrinier 6 through the column 4, and the angle between the Fourdrinier and the Fourdrinier is 90°; the slurry distributor 2 is composed of a box-type container 8 and a slurry distribution weir 9, and there are 9 sets of slurry distribution weirs It is connected to the opening at the bottom of the box-type container and faces the fourdrinier; the slurry distribution weir 9 is designed to have a streamlined converging mouth, and the converging mouth is designed to be adjustable. The converging mouth is composed of an upper lip 11 and a lower lip 10, wherein The upper lip 11 is provided with a hinge mechanism, so that the upper lip 11 can move up and down, and the two sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com