Double seal system for pressurized writing device

A technology for writing devices and sealing elements, which is applied to writing utensils, devices for applying liquid to surfaces, applications, etc., can solve problems such as internal pressure changes, affecting the uniform flow of writing media, and achieve the effect of optimal writing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

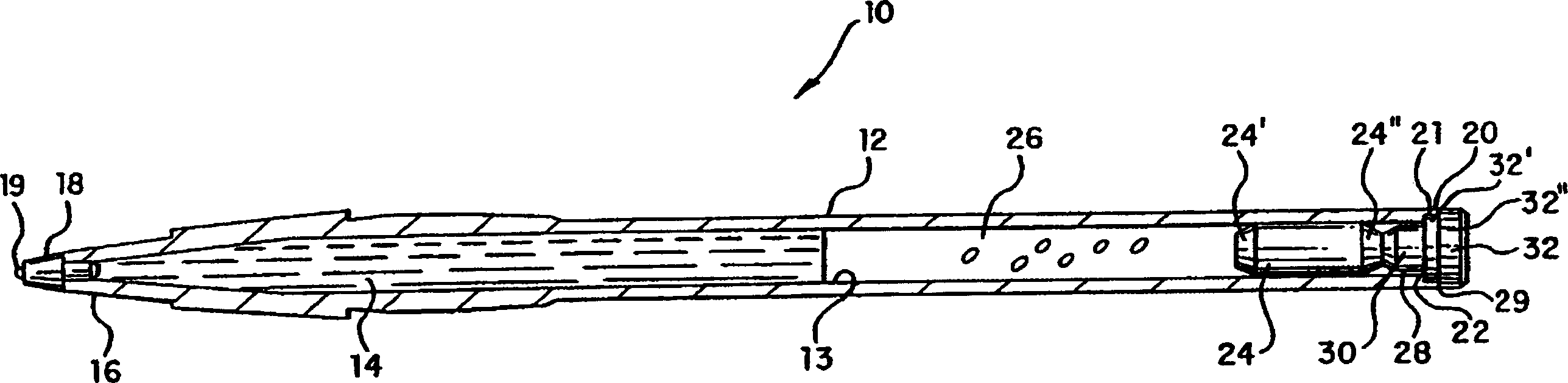

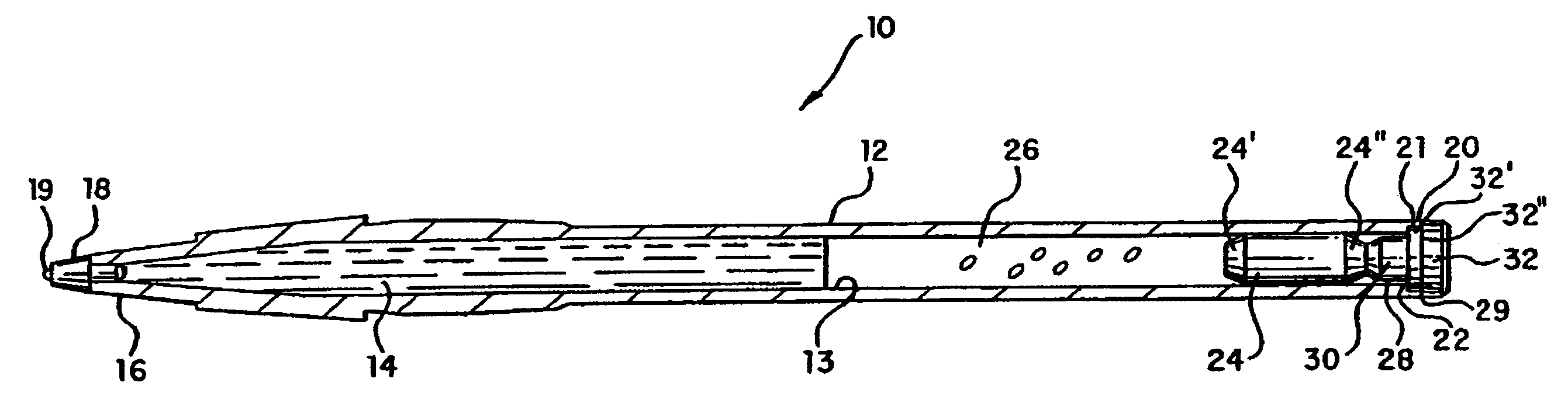

[0016] turn to figure 1 , which shows an embodiment of a writing device 10 constructed in accordance with the present invention, it should be understood that those skilled in the art can modify and replace various elements therein.

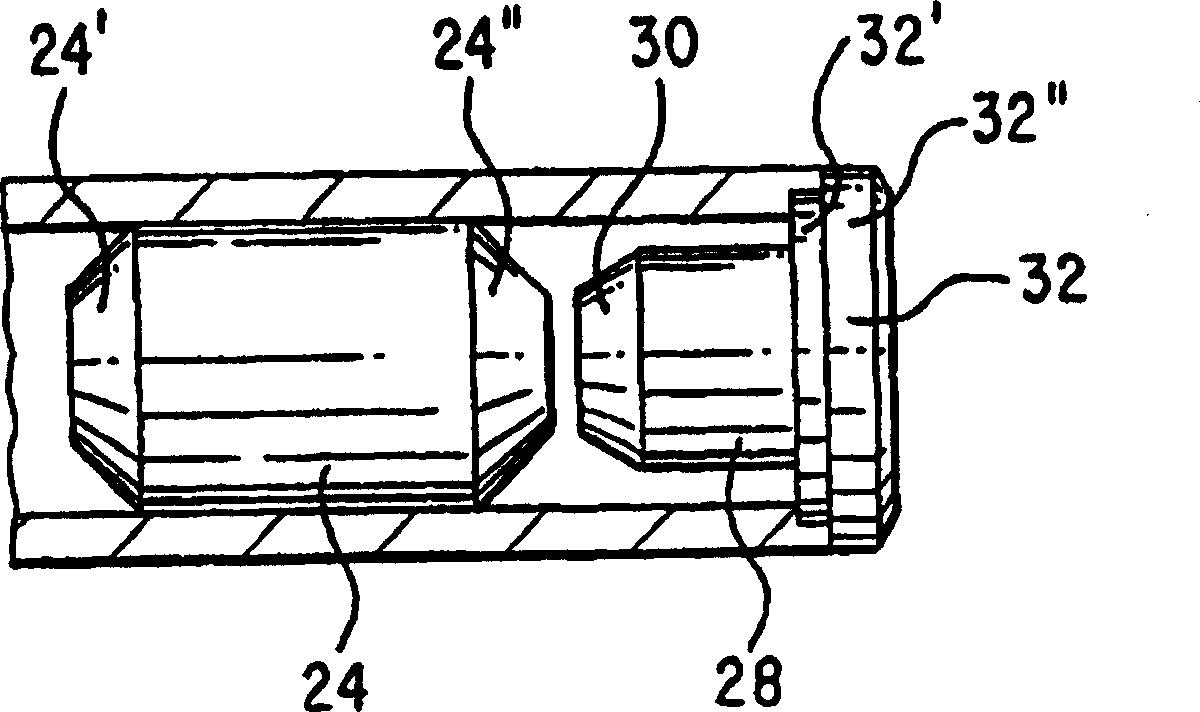

[0017] Writing instrument 10 generally includes a body 12 partially filled with ink 14 . Writing device 10 may stand alone as a writing implement, or may act as a refill inserted into a sleeve or writing implement housing. Body 12 may be formed primarily of a rigid polymer or plastic material, such as nylon, acrylonitrile, butadiene, styrene terpolymer, or similar materials. The main body 12 has a substantially uniform cylindrical shape along the length direction of its inner wall 13 , and gradually tapers toward the first end 16 . On the first end 16 is formed a nib or tip 18 through which an ink tip 19 is disposed. At a second end 20 opposite the first end 16 is an opening 22 through which a first or primary sealing element 24 is inserted. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com