Single shaft double eccentric negative offset rolling shearing machine

A double-eccentric, negative-offset technology, applied in shearing devices, shearing machines, metal processing equipment, etc., to achieve the effect of consistent quality, straight end faces of steel plates, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

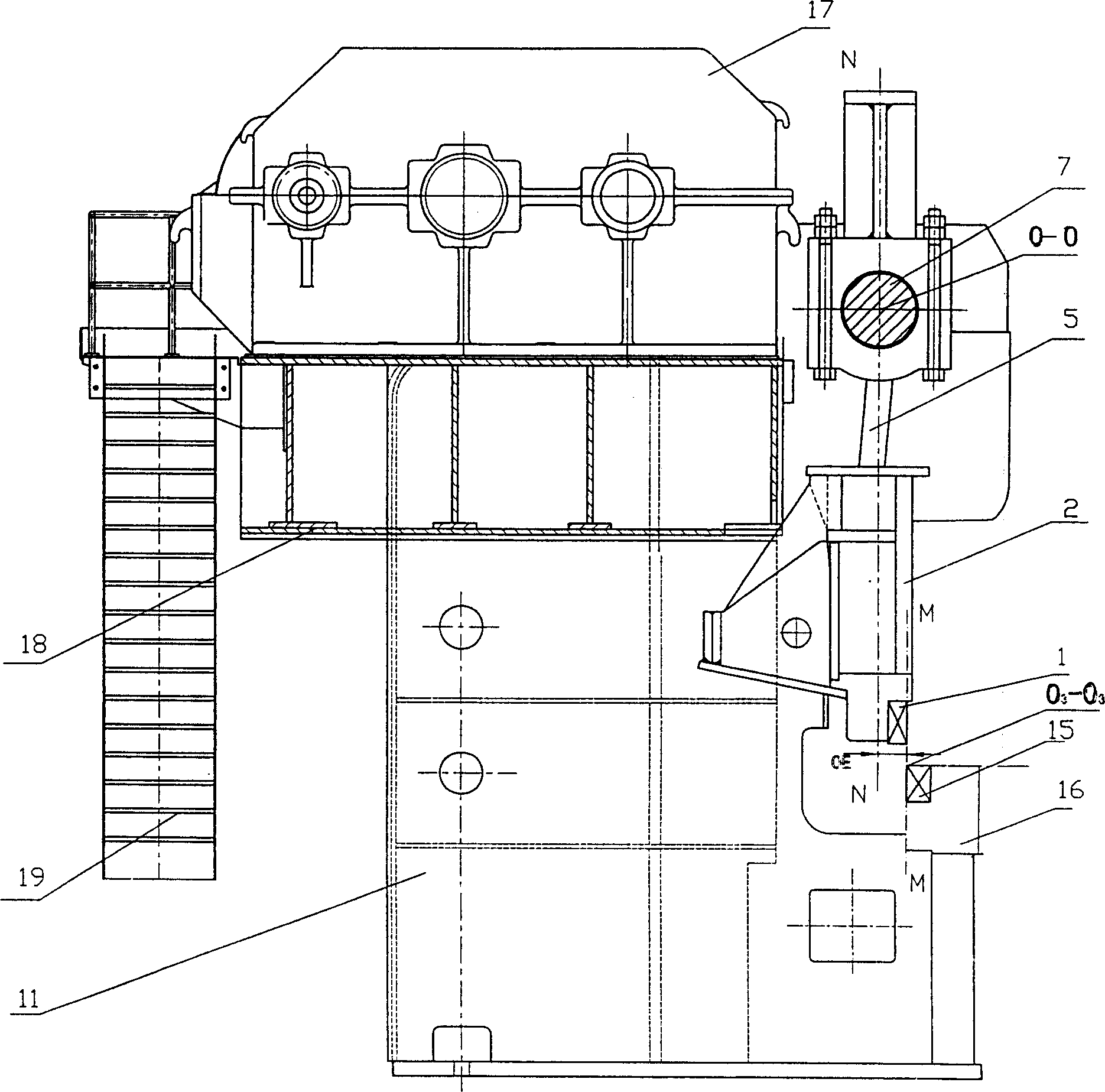

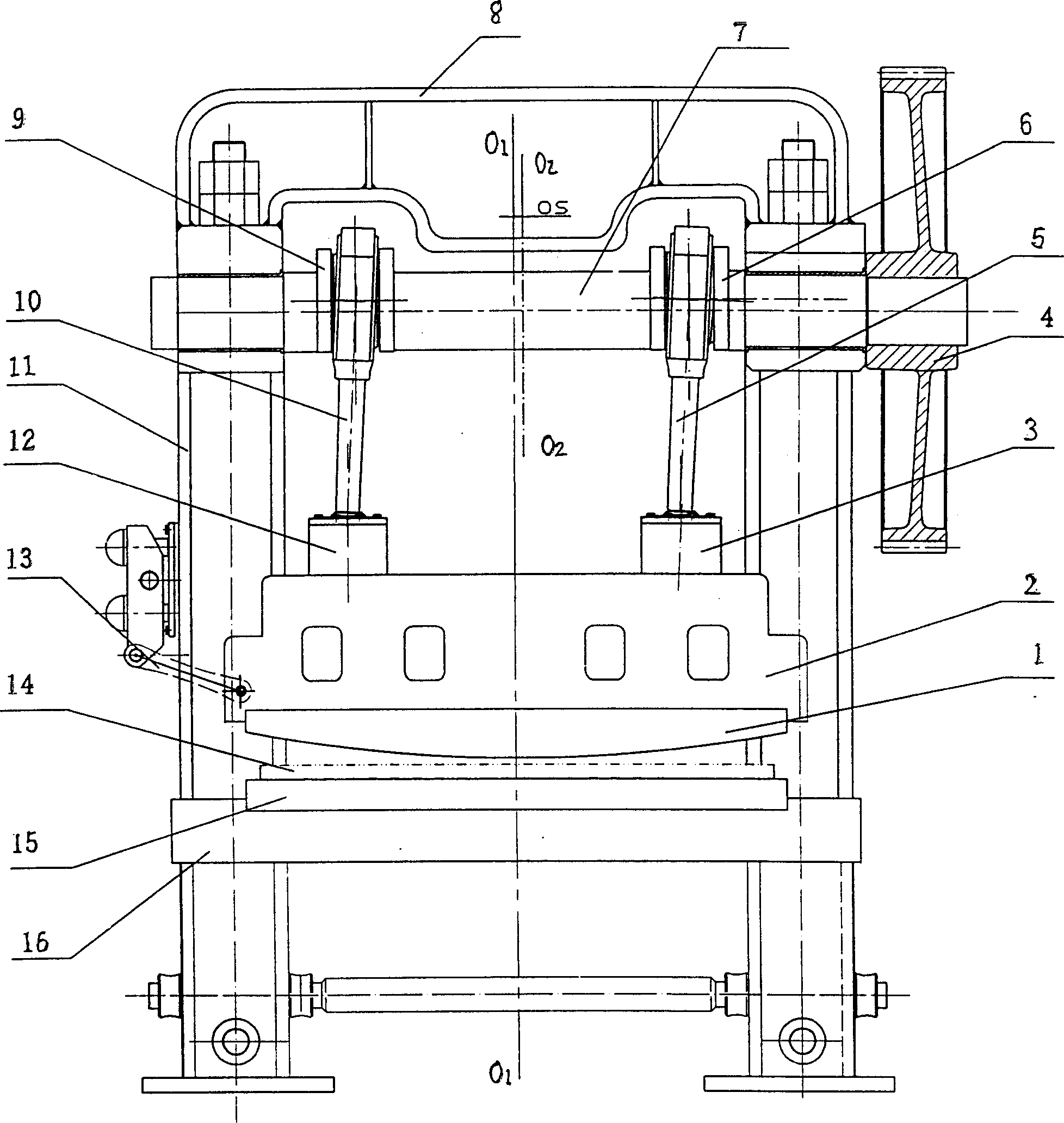

[0051] The embodiment will be further described according to the accompanying drawings. This embodiment is used to illustrate the present invention, but not to limit the present invention.

[0052] In this embodiment, a large-scale rolling shear machine designed by a steel company is taken as an example, and the machine is set as a single-axis double-eccentric negative bias structure. The shear force is 850KN, and the shear steel plate size is 40×2700×6000~120000. 15 cuts per minute.

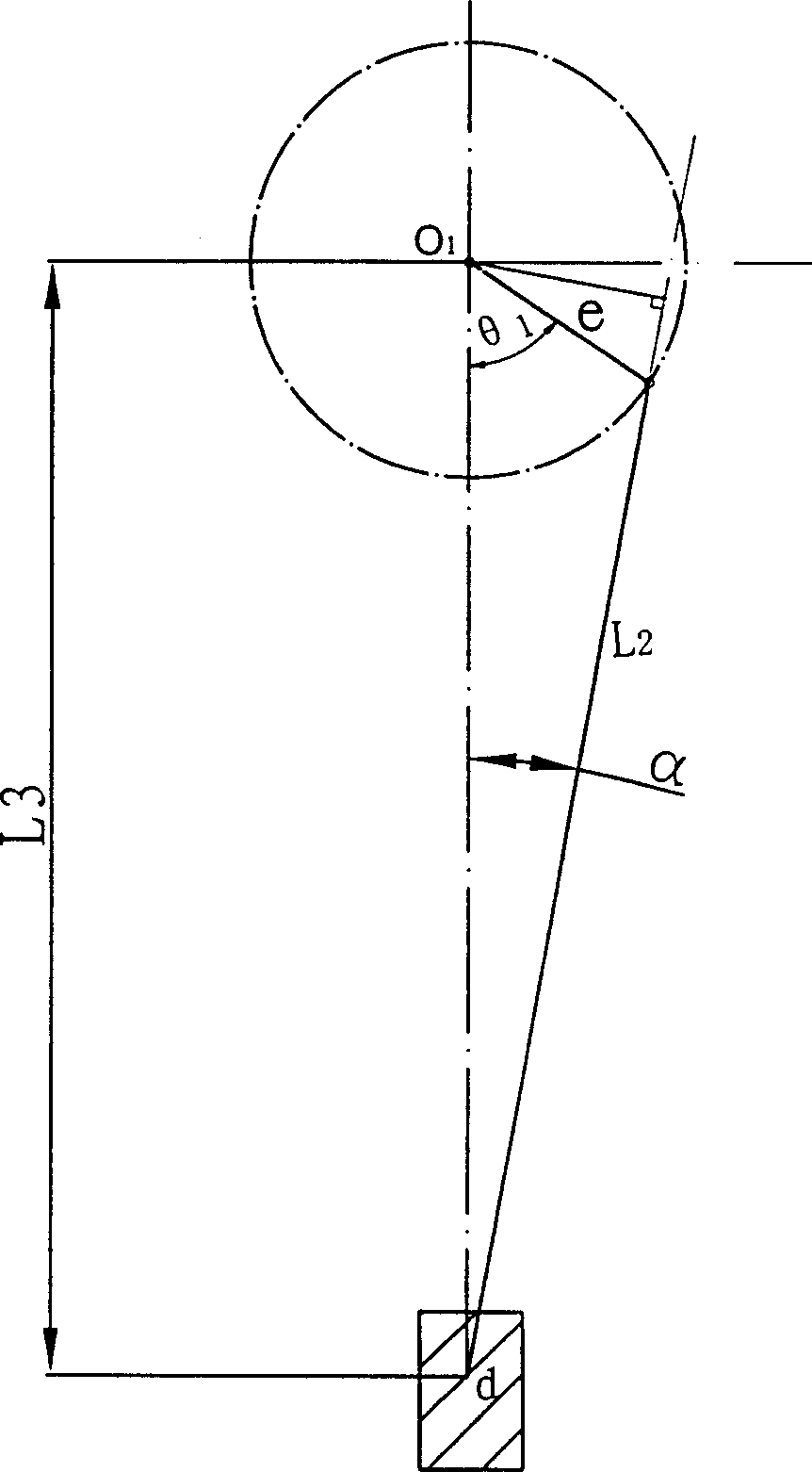

[0053] Single-axis double-eccentric negative-bias rolling shearing machine is composed of frame 11, arc upper shear blade 1, lower shear blade 15, crank linkage mechanism, etc., arc upper scissors 1 are installed on upper tool holder 2, right hinged 3 and the left hinge 12 are installed on the upper tool rest 2, the upper end of the left connecting rod 10 is connected with the left crank 9, the lower end is connected with the left hinge 12, the upper end of the right connecting rod 5 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com