Combined process of treating high concentration and high colority effluent from acetaminophen production

A paracetamol and combined process technology, which is applied in chemical instruments and methods, heating water/sewage treatment, neutralized water/sewage treatment, etc. , can not meet environmental protection requirements and other issues, to achieve the effect of easy promotion, stable chromaticity, and improved biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

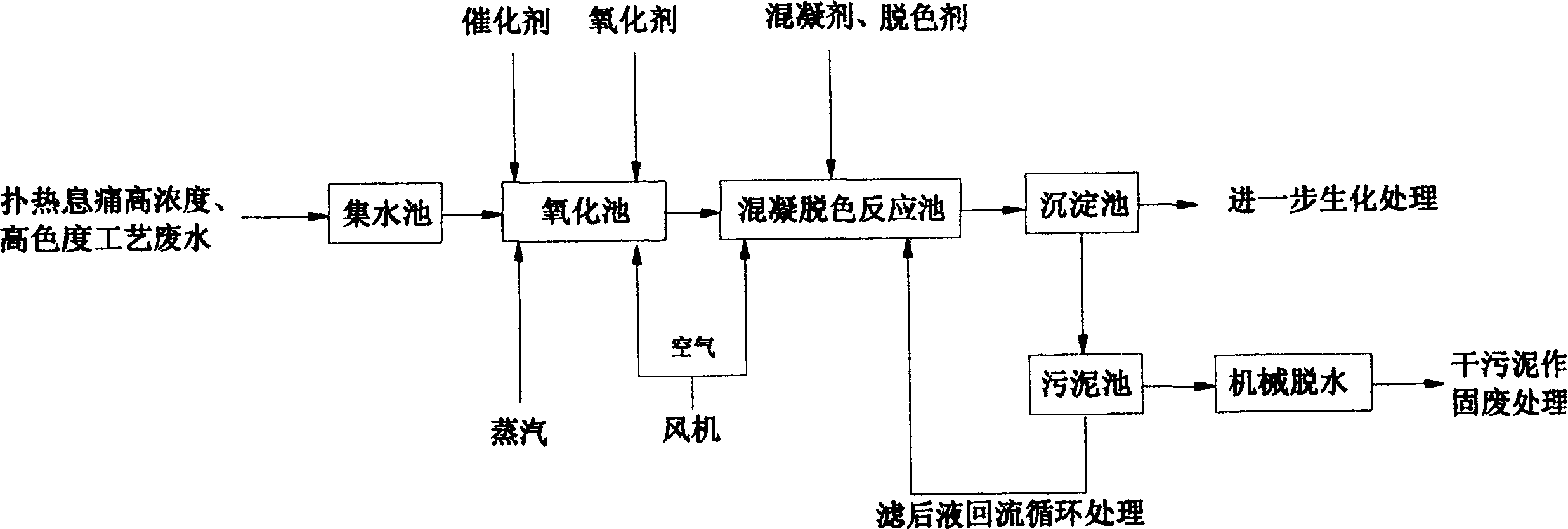

Image

Examples

Embodiment 1

[0034] 20 tons of paracetamol wastewater with high concentration and high chroma is pumped into the oxidation tank, 80 kg of 10% ferrous sulfate solution and 10% manganese sulfate solution are added respectively, and steam is introduced into the oxidation tank to raise the temperature of the wastewater to 98°C. Turn on the aeration device for aeration and oxidation, and at the same time turn on the hydrogen peroxide metering pump to evenly add 222 kg of 30% hydrogen peroxide solution to the oxidation device, and control the addition time for 4 hours. , add 82.5 kg of 30% sodium hydroxide solution, adjust the pH value to 6.8, pump the wastewater into the coagulation decolorization reaction tank, and add 20% polyaluminum chloride solution to the coagulation decolorization reaction tank when the wastewater temperature is 60°C 40 kg, 40 kg of 0.2% polyacrylamide solution, 40 kg of 20% macromolecule flocculation decolorization agent solution, 100 kg of powdered activated carbon, and...

Embodiment 2

[0039] A total of 20 tons of high-concentration, high-color paracetamol wastewater and part of the cooling water are pumped into the oxidation tank, and 40 kg of 10% ferrous sulfate solution and 10% manganese sulfate solution are added respectively, and steam is passed into the oxidation tank to decompose the wastewater. Raise the temperature to 80°C, turn on the aeration device to aerate and oxidize, and at the same time turn on the hydrogen peroxide metering pump to evenly add 12.3 kg of 30% hydrogen peroxide into the oxidation tank, control the adding time for 3 hours, and continue to maintain the temperature of 100°C after the oxidant is added. Oxidation for 6 hours, after that, add 18 kg of 30% sodium hydroxide solution, adjust the pH value to 6.3, pump the waste water into the coagulation decolorization reaction tank, and add 20 50 kg of % polyaluminum chloride solution, 50 kg of 0.2% polyacrylamide solution, 50 kg of 20% macromolecule flocculation and decolorization agen...

Embodiment 3

[0044] 20 tons of paracetamol wastewater with high concentration and high chroma is pumped into the oxidation tank, 100 kg each of 10% ferrous sulfate solution and 10% manganese sulfate solution are added, and steam is introduced into the oxidation tank to raise the temperature of the wastewater to 80°C. Turn on the aeration device for aeration and oxidation, and at the same time turn on the hydrogen peroxide metering pump to evenly add 155 kg of 30% hydrogen peroxide to the oxidation device, and control the addition time for 5 hours. , add 70 kg of 30% sodium hydroxide solution, adjust the pH value to 6.6, pump the wastewater into the coagulation decolorization reaction tank, and add 20% polyaluminum chloride solution to the coagulation decolorization reaction tank when the wastewater temperature is 50°C 100 kg, 100 kg of 0.2% polyacrylamide solution, 100 kg of 20% macromolecule flocculation and decolorization agent solution, 120 kg of powdered activated carbon, stirred with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com