Actuator for valve, in particular turbine valve

A technology of regulating mechanism and valve stem, which is applied in the direction of valve details, valve operation/release device, valve device, etc., can solve the problems of troublesome maintenance measures, high cost, poor stability, etc., and achieve the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

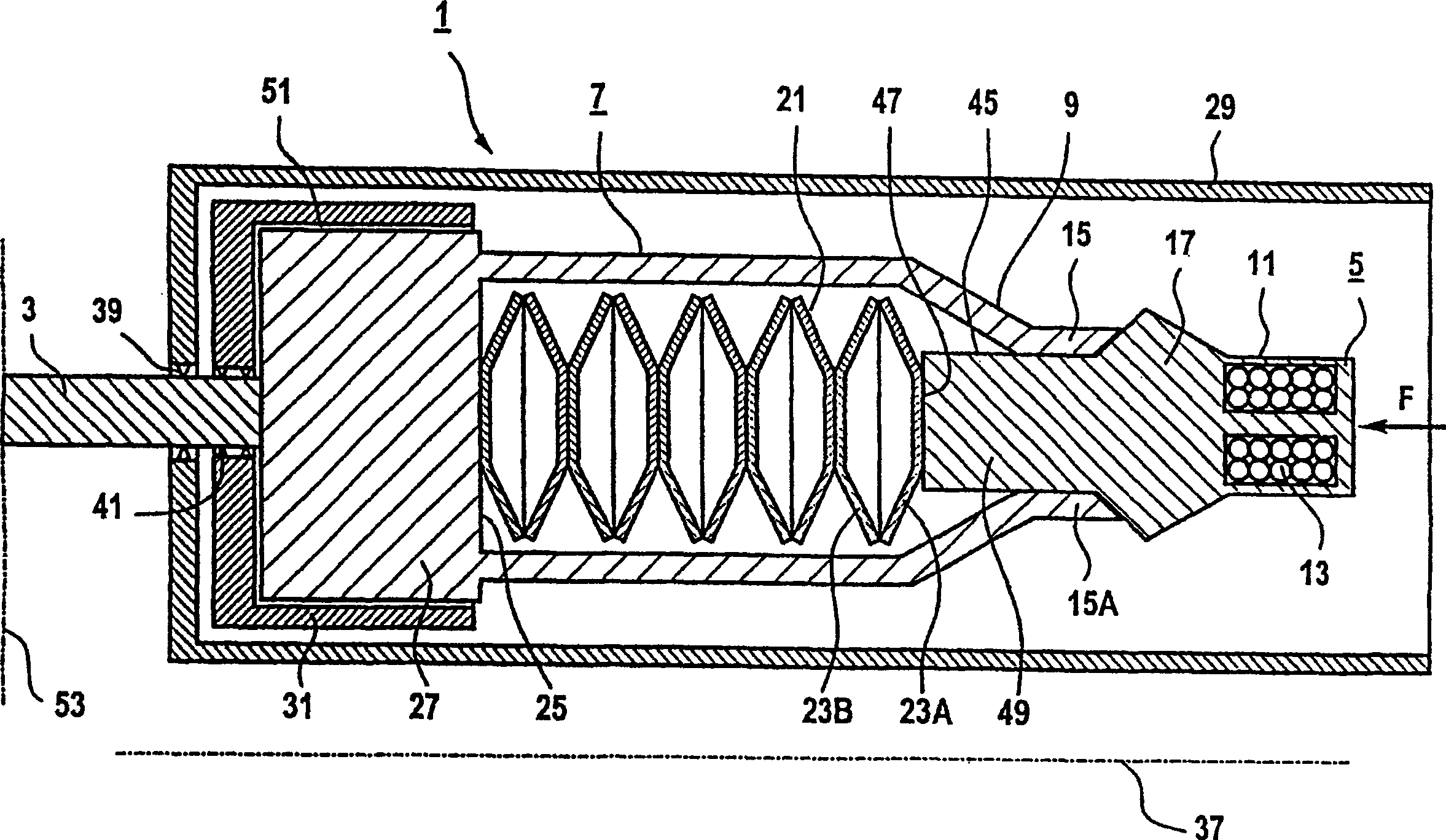

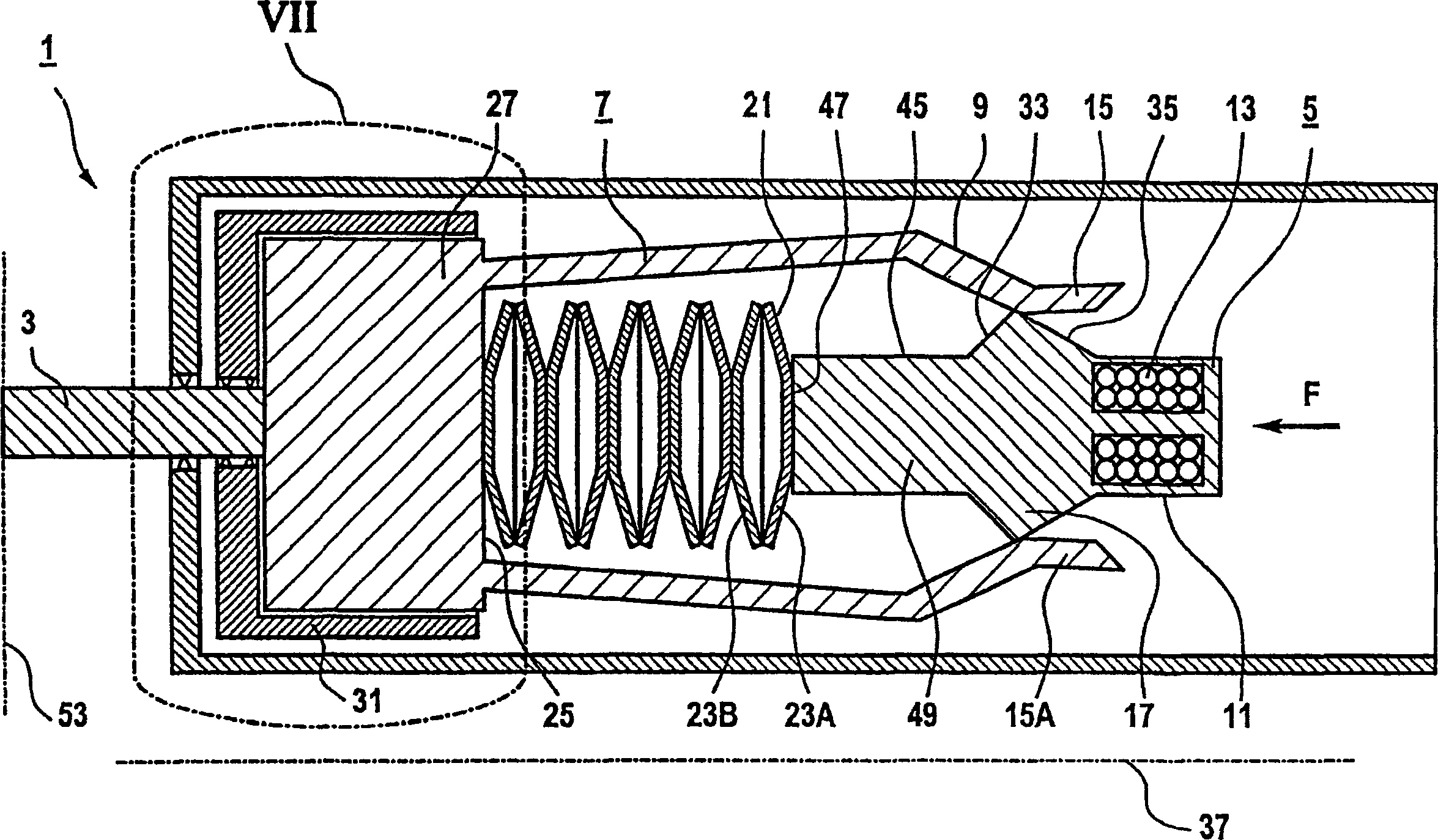

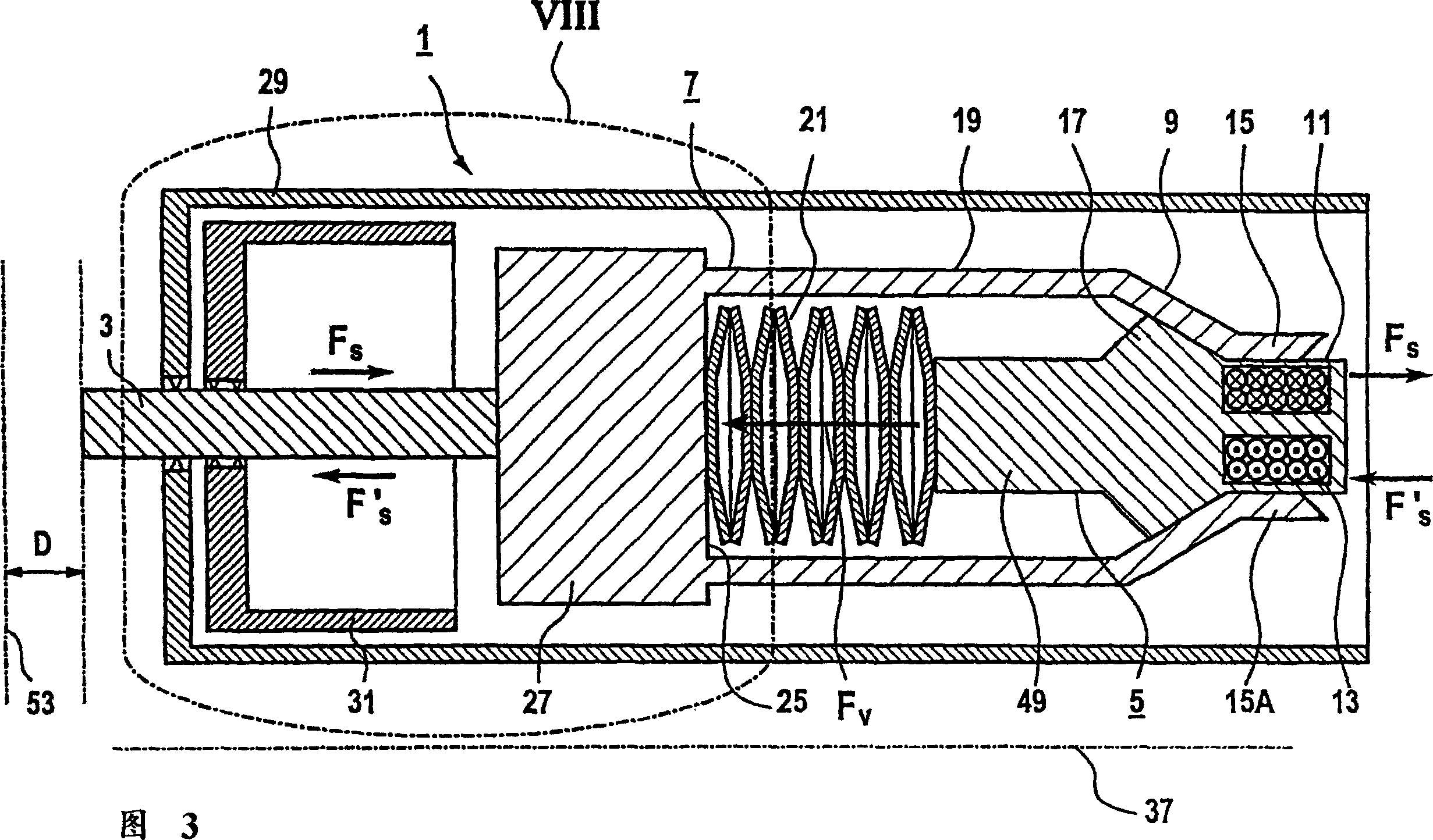

[0049] figure 1 A longitudinal sectional view of the adjusting mechanism 1 of a valve, in particular a turbine valve, is shown. The adjustment mechanism extends along a longitudinal axis 37, and along the axis 37 there are successively one for adjusting figure 1 Valve rod 3 , an energy storage device 7 and a drive element 5 in the opening position of the valve, not shown in detail. The drive part 5 , the energy storage device 7 and the valve rod 3 are here arranged at least partially in a housing 29 . The energy storage device has a spring element 21 , wherein the spring element 21 is assembled from a plurality of disk springs 23A, 23B arranged along a longitudinal axis 37 adjacent to each other. The driving part 5 is coupled to the valve stem 3 via an energy storage device 7 . The energy storage device 7 is coupled to the valve stem 3 via a damping piston 27 formed on the bottom 5 of the energy storage device 7 . To this end, the valve stem 3 is connected to the damping p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com