Constant-volume dispensing coating container

A quantitative liquid and coating technology, which is applied in the field of containers where liquid is poured out, can solve the problems of insufficient anti-detachment effect of the lamination edge, deformation, and the effect of not improving the feeling of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0165] best practice

[0166] Embodiments of the present invention will be described below with reference to the accompanying drawings.

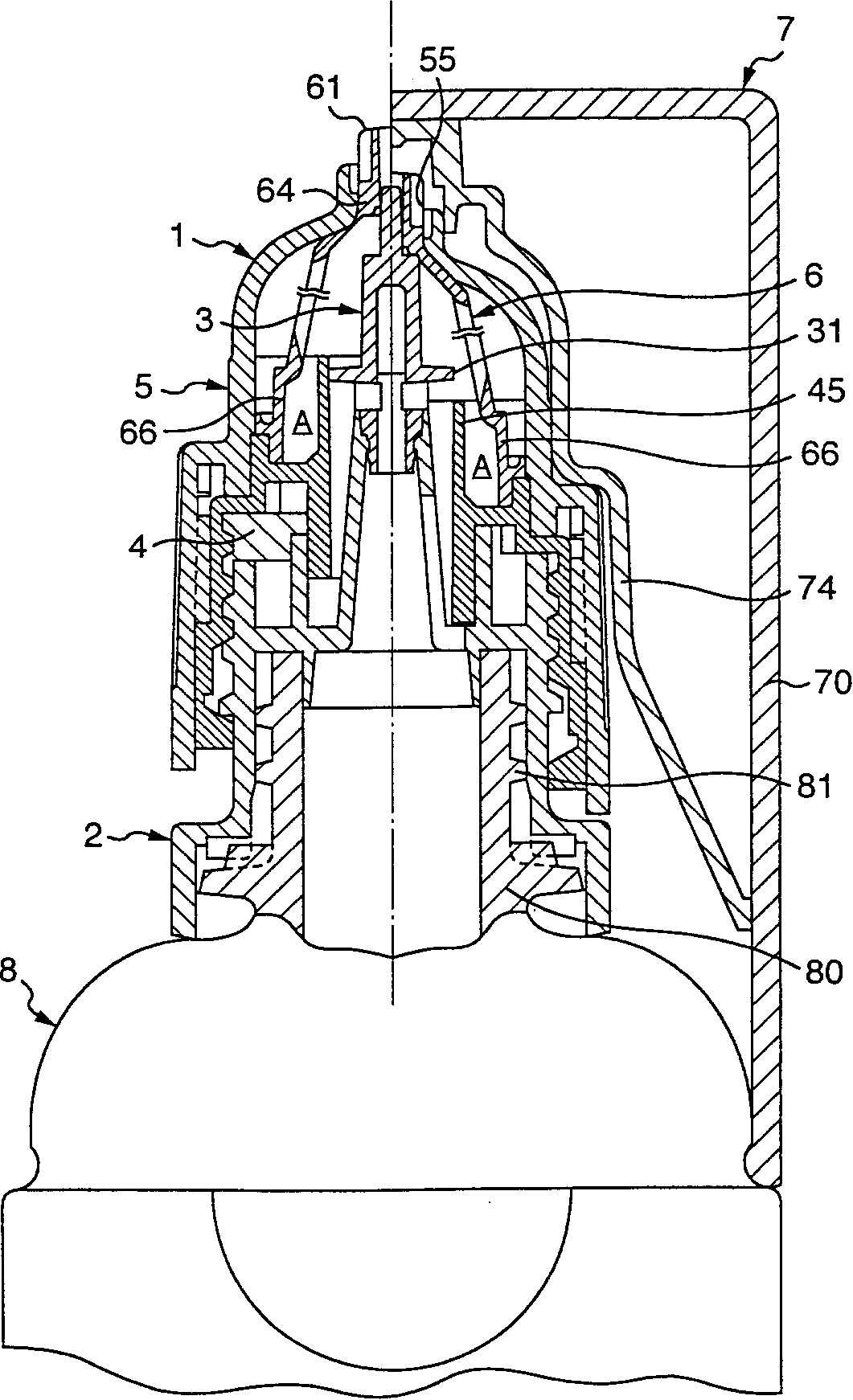

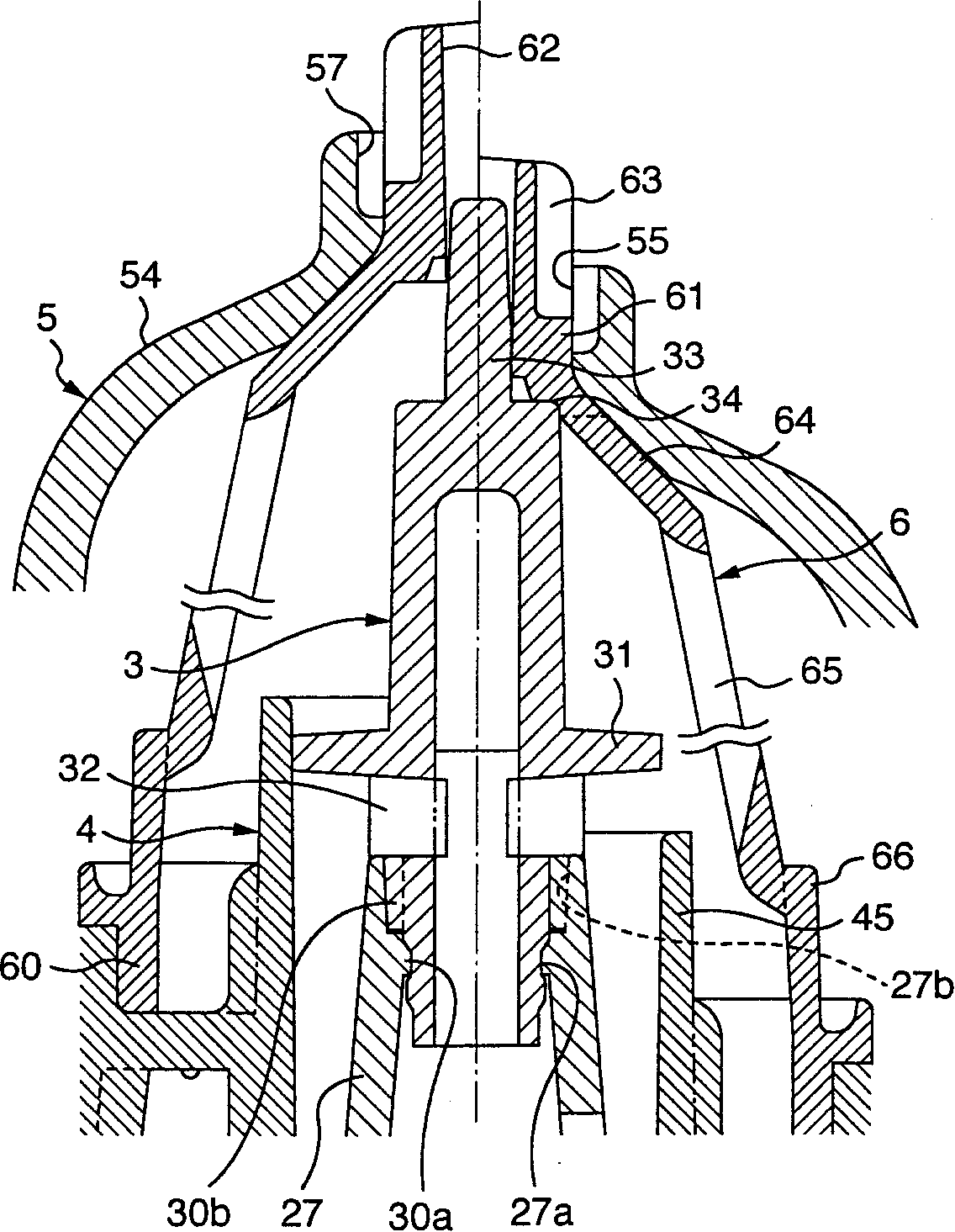

[0167] figure 1 is an overall vertical cross-sectional view, wherein the coating locking device 1 is fixed on the bottle mouth tube 80 of the bottle device 8 . exist figure 1 In , the right half represents the non-use state and measurement state of the container for injecting and applying a fixed amount of liquid, while the left half represents its use state and application state.

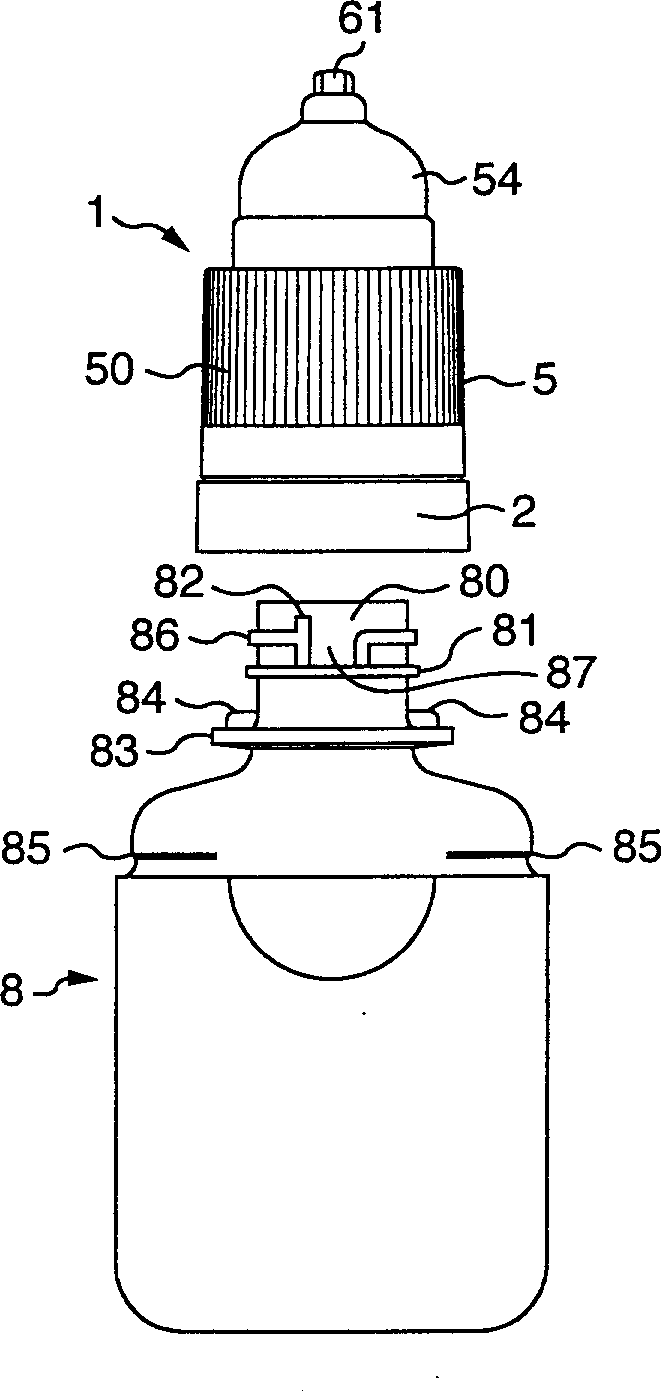

[0168] Coating locking device 1 is fixed on the bottleneck tube 80, and the bottleneck tube 80 of bottle device 8 ( image 3 ) is provided with an annular stop rib 81, a vertical stop rib 82, a circumferential rib 86, an external flange 83 and a pair of protrusions 84, and the annular stop rib 81 is arranged on the bottle mouth In the middle part of the outer peripheral surface of the tube, the vertical stop rib 82 is arranged on the upper region of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com