Method of separating colouring agents from recycled fibre material

A technology for recycling fibers and colorants, which is applied in the fields of raw material separation, fiber raw material processing, paper recycling, etc. It can solve the problems of loss of fiber materials, reduction of pulp whiteness, difficult separation of colorants, etc., and achieve the effect of avoiding excessive decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

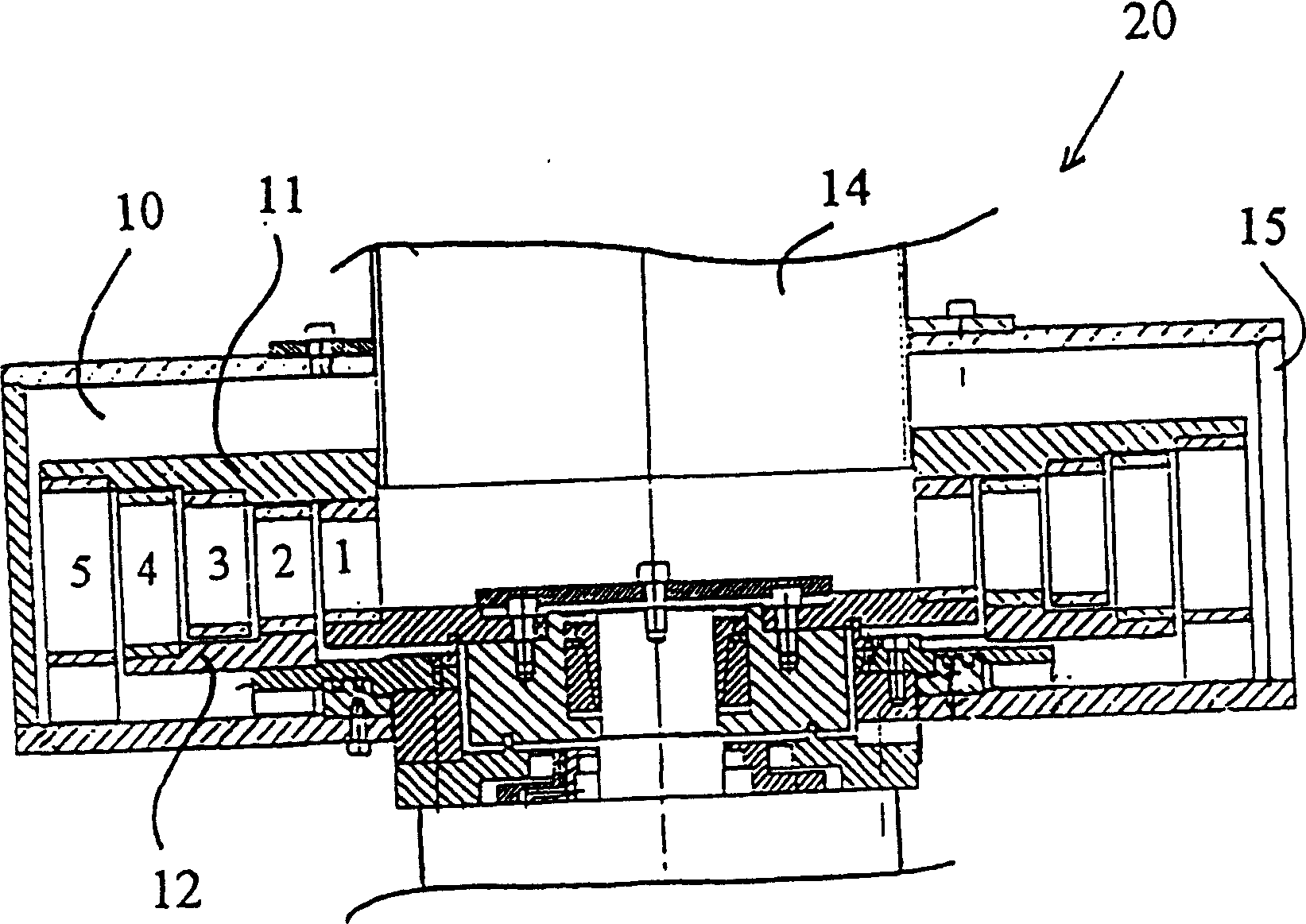

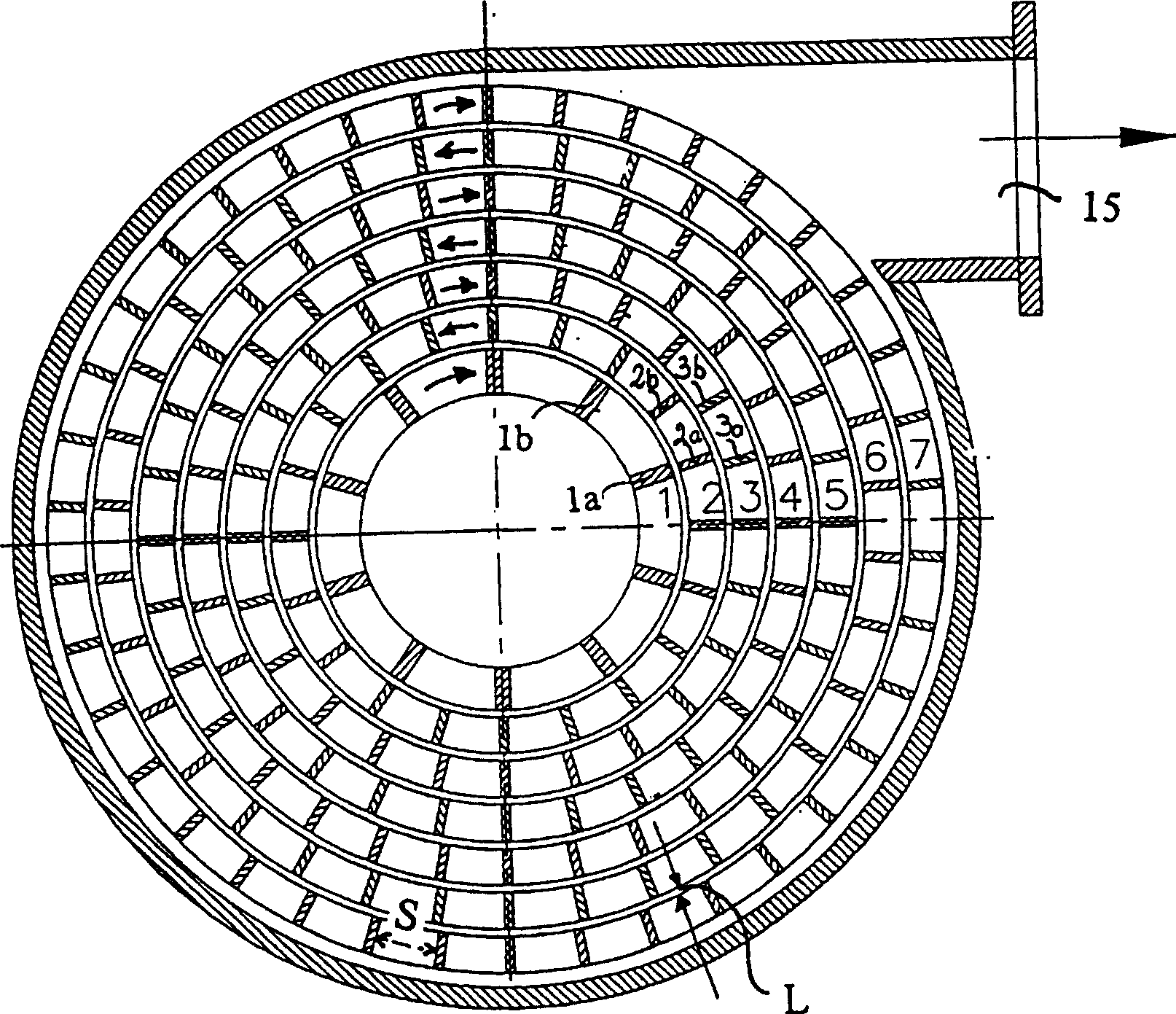

[0012] figure 1 is a longitudinal section of a double-acting impact mill 20 used in the method of the invention, comprising a housing 10 in which is arranged a rotor 11 having impact surfaces 1a, 1b..., 3a, 3b...etc. figure 2 The individual impact surfaces are given in detail. A second rotor 12 coaxial with the first rotor 11 is also arranged in the casing. The second rotor 12 also has impact surfaces 2a, 2b..., 4a, 4b...etc. The impact surfaces 1a, 1b, . . . , 2a, 2b, . The rings 1 , 3 , 5 of the first rotor 11 and the rings 2 , 4 of the second rotor 12 overlap each other. This enables the rotors 11 and 12 and their impact surfaces to freely rotate coaxially in different directions.

[0013] The housing ends with a hole 14 leading to the center of the rotors 11 and 12, the hole 14 being the feed port for the pre-shredded recycled fibrous material. The wall of the housing has an opening 15, which is the discharge opening, tangentially towards the outermost impact surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com