Method for driving plasma display panel

A plasma display and drive waveform technology, applied in the direction of static indicators, instruments, color TV components, etc., can solve the problems of unable to turn on the unit that must be turned on, redundant, AY wall voltage reset failure rate increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

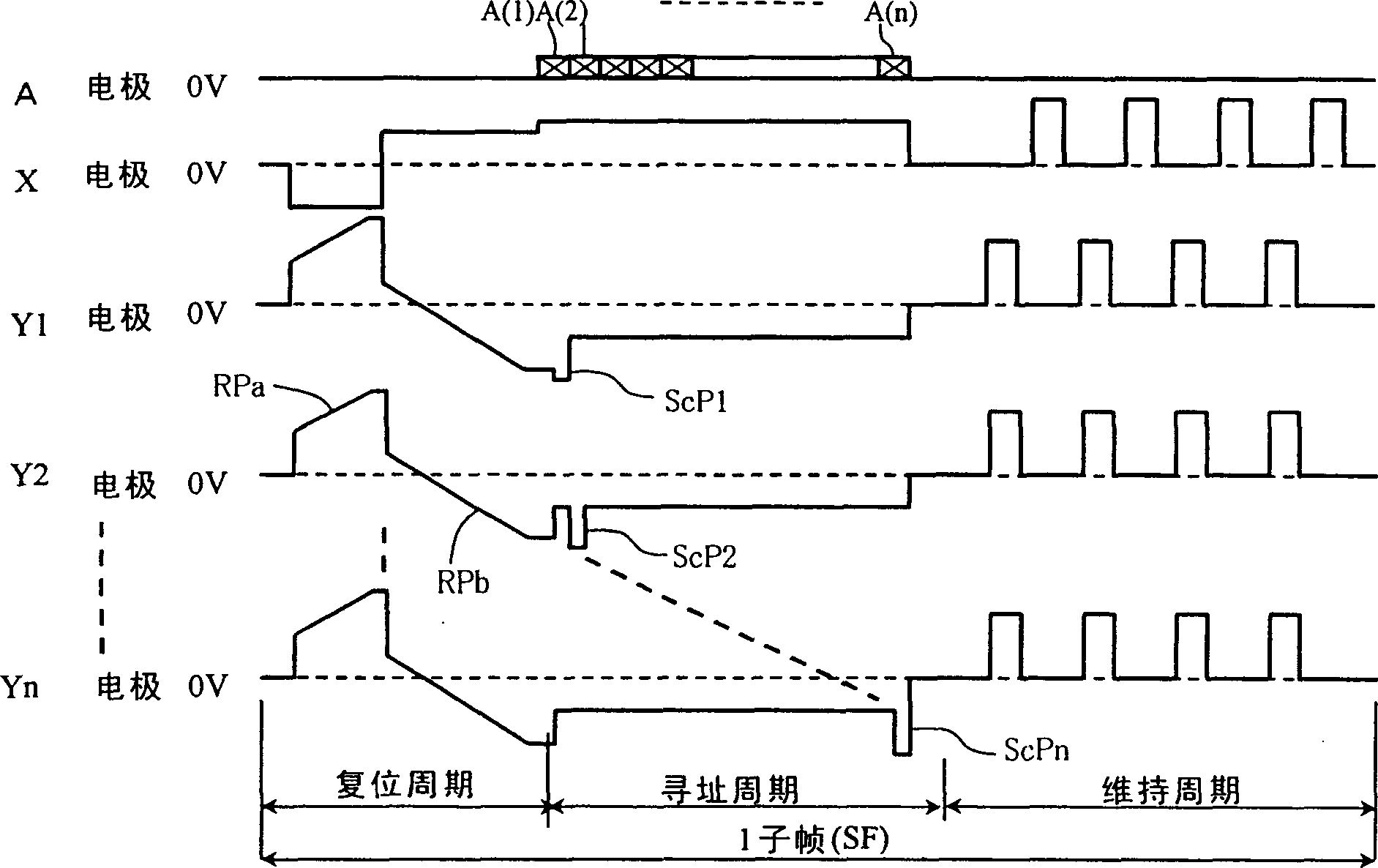

[0143] Reference Figure 16 , The driving waveform and the reset condition formula according to the first embodiment of the present invention will be described.

[0144] In the first embodiment, in the sustain period, ±V S A pulse train of / 2 is applied to the X electrode and the Y electrode, and the potential of the A electrode is fixed at the ground potential. Consider the voltage between the electrodes, ±V S The alternating waveform is applied between the X electrode and the Y electrode, ±V S An alternating waveform of / 2 is applied between the A electrode and the Y electrode. In the sustain period, the bias voltage of the AY applied voltage (ie, the AY wall voltage) is zero.

[0145] The reset condition formula according to the first embodiment is:

[0146] 2V tAY -V tXY ≤V YR -V XR .

[0147] Because the discharge threshold voltage V tAY The general value of is approximately 200V, and the discharge threshold voltage V tXY The general value of is approximately 230V, so the fol...

no. 2 example

[0153] Reference Figure 17 , The driving waveform and the reset condition formula according to the second embodiment of the present invention will be described.

[0154] From 0 to V S The sustain driving waveform composed of alternating pulses is applied to the X electrode and the Y electrode, and the potential of the address electrode is fixed to zero. The voltage amplitude V applied to the X electrode when the ramp wave is applied to the X electrode in the second step of resetting the waveform XR And the voltage amplitude applied to the Y electrode -V YR When the following reset conditions are met:

[0155] 2V tAY -V tXY ≤V YR -V XR +V S

[0156] "Simultaneous reset guarantee area" and "maintain operation line" accord with Figure 15 (a) The relationship in.

[0157] As in the first embodiment, the general settings are as follows:

[0158] 2V tAY -V tXY= 170.

[0159] By setting the following formula to 170V or greater:

[0160] V YR -V XR +V S

[0161] "XY and AY discharge a...

no. 3 example

[0165] Reference Figure 18 , The driving waveform and the reset condition formula according to the third embodiment of the present invention will be described. The sustain driving waveform in the third embodiment is considered to be a waveform based on the driving waveform in the first embodiment, and it has several pulses at the end of the sustain period, that is, the sustain pulse of the second embodiment is applied.

[0166] The sustain drive pulse will be ±V immediately before the end of the sustain period s1 / 2 alternating pulse is applied to the X electrode and Y electrode, and will change from 0 to V until the end of the sustain period s2 The alternating pulse is applied to the X electrode and Y electrode. The potential of the address electrode is set to zero.

[0167] The amplitude of the voltage applied to the X electrode when the ramp wave is applied to the X electrode through the second step of the reset waveform V XR And the voltage amplitude applied to the Y electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com