Waste acid recovery

A technology of sulfuric acid and waste liquid, applied in the direction of sulfur trioxide/sulfuric acid, sulfur compounds, products, etc., to achieve the effect of reducing the amount of sulfuric acid and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

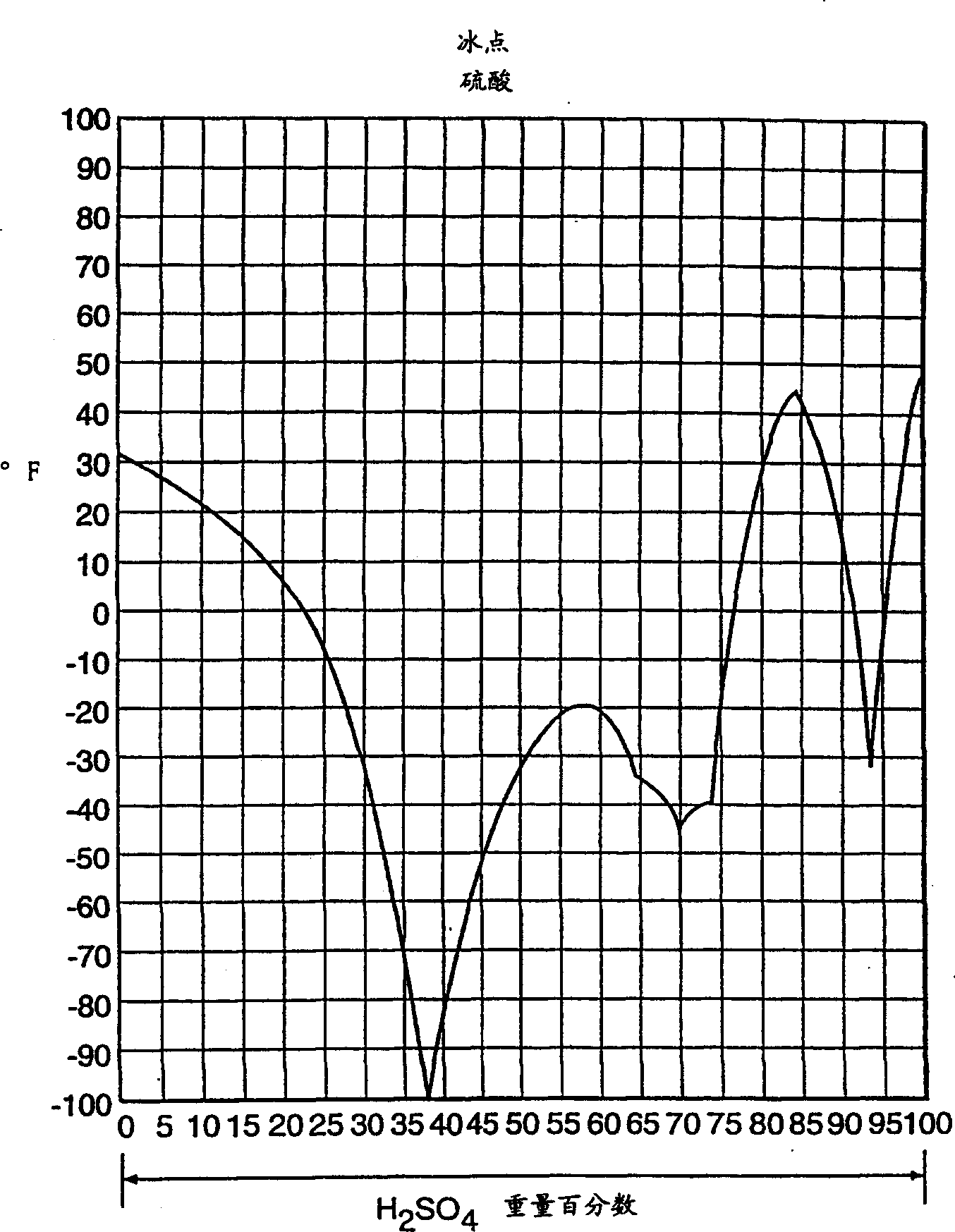

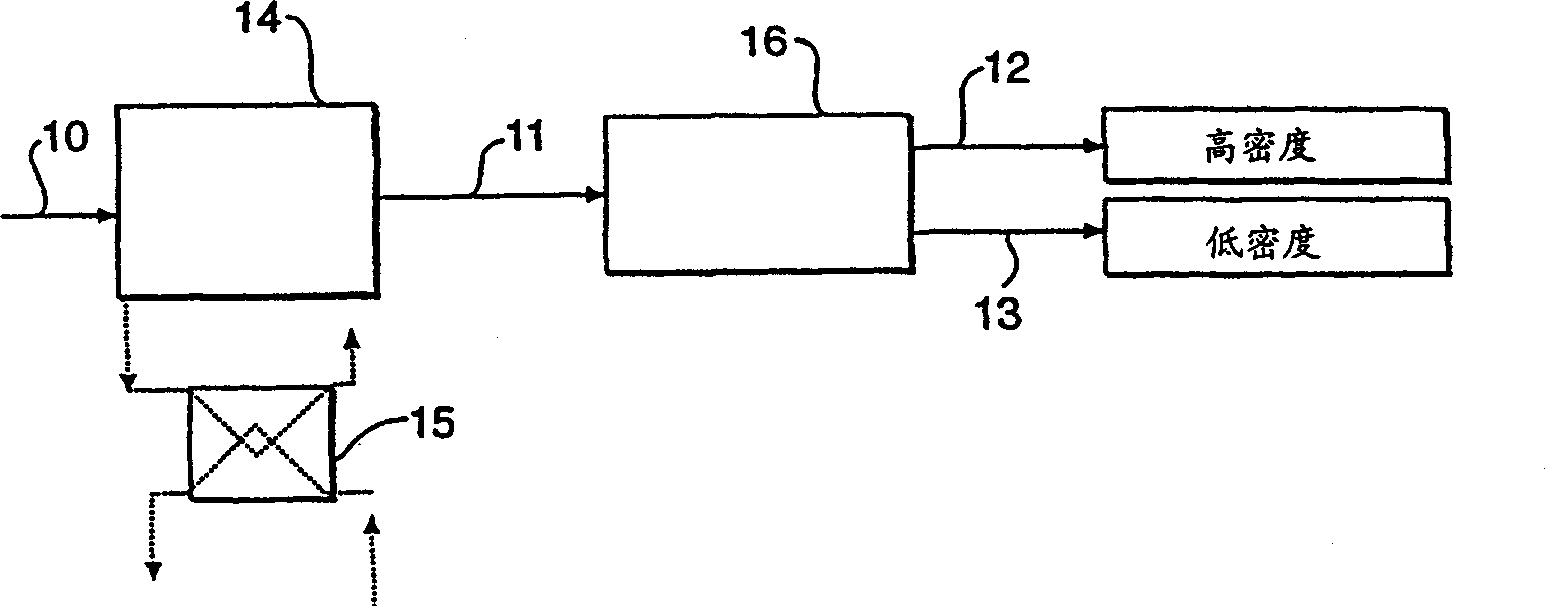

[0066] Five sets of experiments were carried out on organic waste liquids containing different amounts of sulfuric acid. In the test, the organic waste liquid was fed into the freeze concentration equipment shown in Figure 8. During test operation, heat exchanger 406 cooled the refrigerant from an inlet temperature of 10-20°F to an outlet temperature of about 0-20°F. The cooled refrigerant is then pumped through crystallizer 404 to provide a crystallizer 404 inlet temperature of about 0-20°F and an outlet temperature of about 5-30°F. This cools the crystallizer 404 and the organic effluent passing through the crystallizer is cooled to an outlet temperature of about 45°F. The operating time of the test is approximately 4 hours.

[0067] Test No. 1 2 3 4 5 Feed 76.7 76.9 78.1 78.4 78.6 separated acid phase 87.7 87. 87.9 88.0 87.6 Test No. 1 2 3 4 5 Feed 6.7 6.7 6.7 7.4 7.4 separated acid phase 0.27 0.26 0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com