Method and apparatus for preparing mixed powder of nano gold and sodium chloride

A technology of mixing powder and sodium chloride, applied in mixing methods, chemical instruments and methods, dissolution and other directions, can solve problems such as unfavorable dispersants for the human body, affecting the use of nano-gold, etc., and achieves low cost, environmental friendliness, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

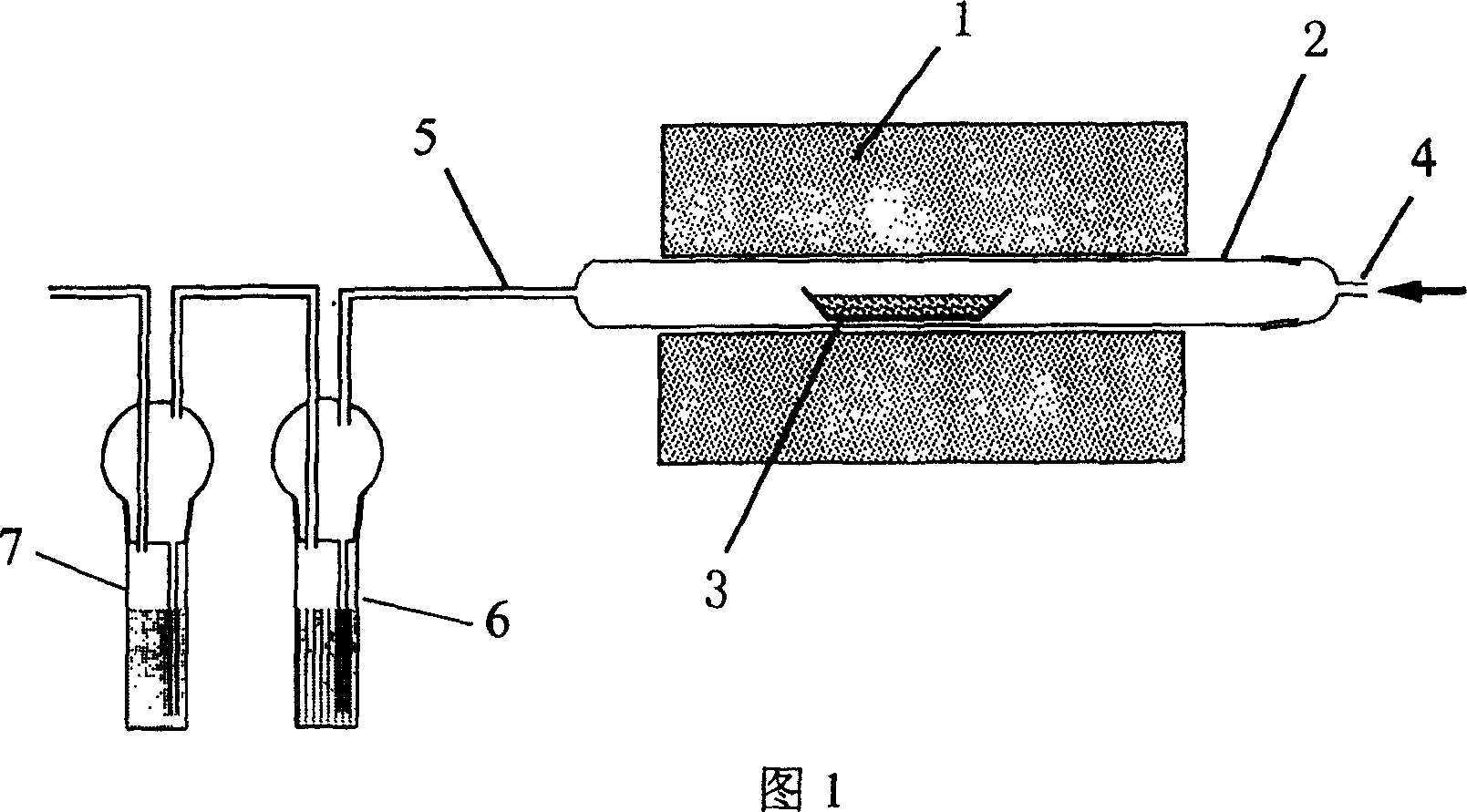

Method used

Image

Examples

Embodiment 1

[0017] 1) Auric acid chloride (HAuCl 4 4H 2 O) aqueous solution 25ml;

[0018] 2) Add 4.7g of sodium chloride into the aqueous chloroauric acid solution, after the sodium chloride is completely dissolved, dry it at 70°C, then grind and pulverize it;

[0019] 3) Put the powder obtained in step 2) into the ceramic boat of the heating device, pass in argon gas, the flow rate of argon gas is 1 liter / min, and after heating at 250°C for 1 hour, lower the furnace temperature while continuing to ventilate, Until room temperature, a mixed powder of nano gold and sodium chloride with a gold content of 2.5% is obtained.

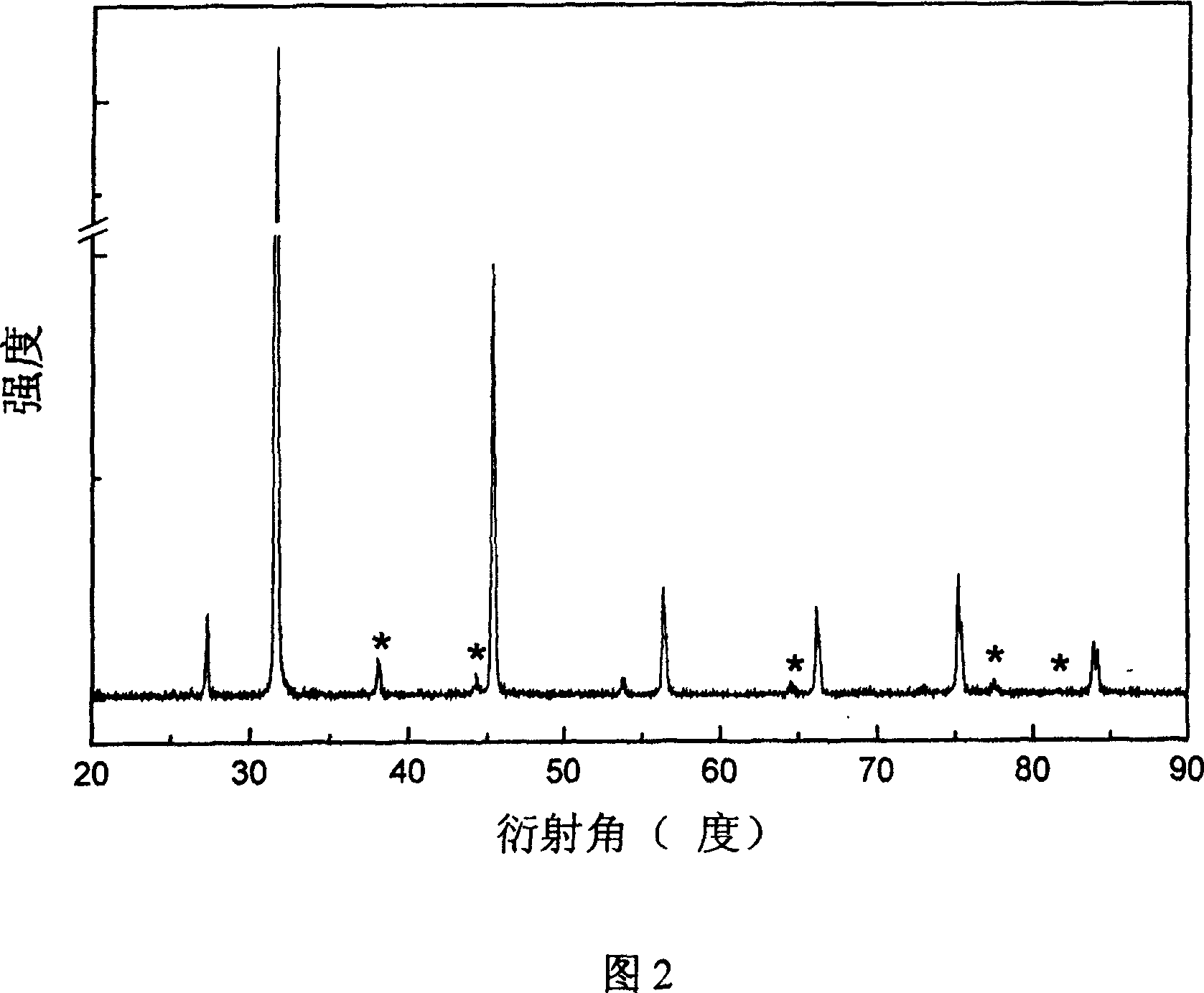

[0020] Fig. 2 is the X-ray diffraction pattern of the mixed powder of nanometer gold and sodium chloride that makes, and the average particle size of gold is 56nm, and " * " sign has marked the diffraction peak of gold among the figure, and remaining diffraction peak is sodium chloride .

Embodiment 2

[0022] 1) Auric acid chloride (HAuCl 4 4H 2 O) aqueous solution 25ml;

[0023] 2) Add 4.7g of sodium chloride into the chloroauric acid aqueous solution, after the sodium chloride is completely dissolved, dry it at 80°C, then grind and pulverize it;

[0024] 3) Put the powder obtained in step 2) into the ceramic boat of the heating device, pass in argon gas, the flow rate of argon gas is 1 liter / min, and after heating at 300°C for 2 hours, lower the furnace temperature while continuing to ventilate, Until room temperature, a mixed powder of nano gold and sodium chloride with a gold content of 2.5% is obtained.

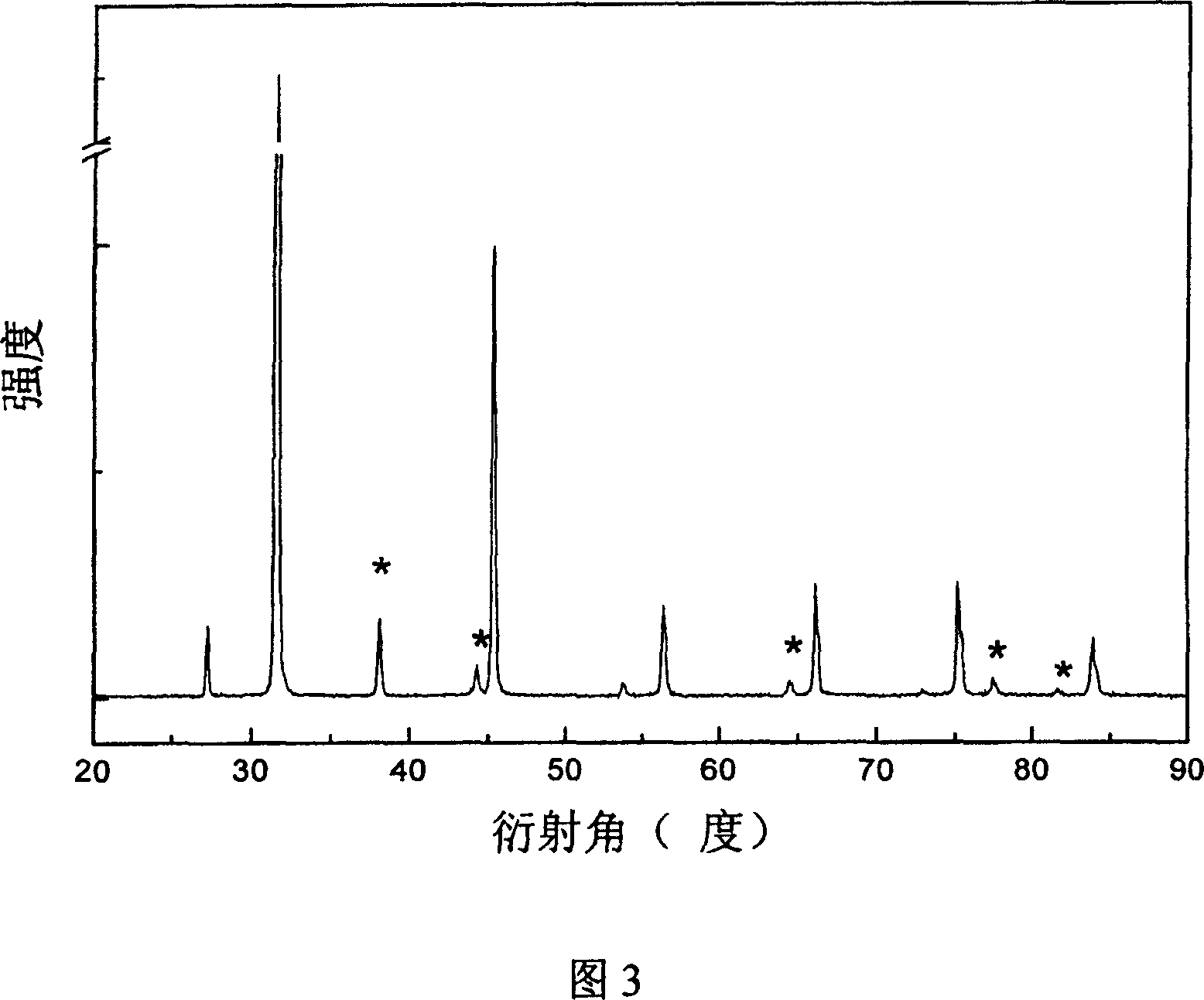

[0025] Fig. 3 is the X-ray diffraction pattern of nanometer gold and sodium chloride mixed powder, and the average particle size of gold is 90nm, and " * " sign among the figure has marked the diffraction peak of gold, and all the other diffraction peaks are sodium chloride.

Embodiment 3

[0027] 1) prepare 4.0% auric acid chloride (HAuCl) with deionized water concentration 4 4H 2 O) aqueous solution 25ml;

[0028] 2) Add 4.3g of sodium chloride into the chloroauric acid aqueous solution, after the sodium chloride is completely dissolved, dry it at 85°C, then grind and pulverize it;

[0029] 3) Put the powder obtained in step 2) into the ceramic boat of the heating device, pass in argon gas, the flow rate of argon gas is 5 liters / minute, and after heating at 350°C for 1 hour, lower the furnace temperature while continuing to ventilate, Until room temperature, a mixed powder of nano gold and sodium chloride with a gold content of 10.0% is obtained.

[0030] Fig. 4 is the X-ray diffractogram of nanometer gold and sodium chloride mixed powder, and the average grain size of gold is 95nm, and " * " sign among the figure marks the diffraction peak of gold, and all the other diffraction peaks are sodium chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com