Laminated piezoelectric transducer

A piezoelectric transformer, layered technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

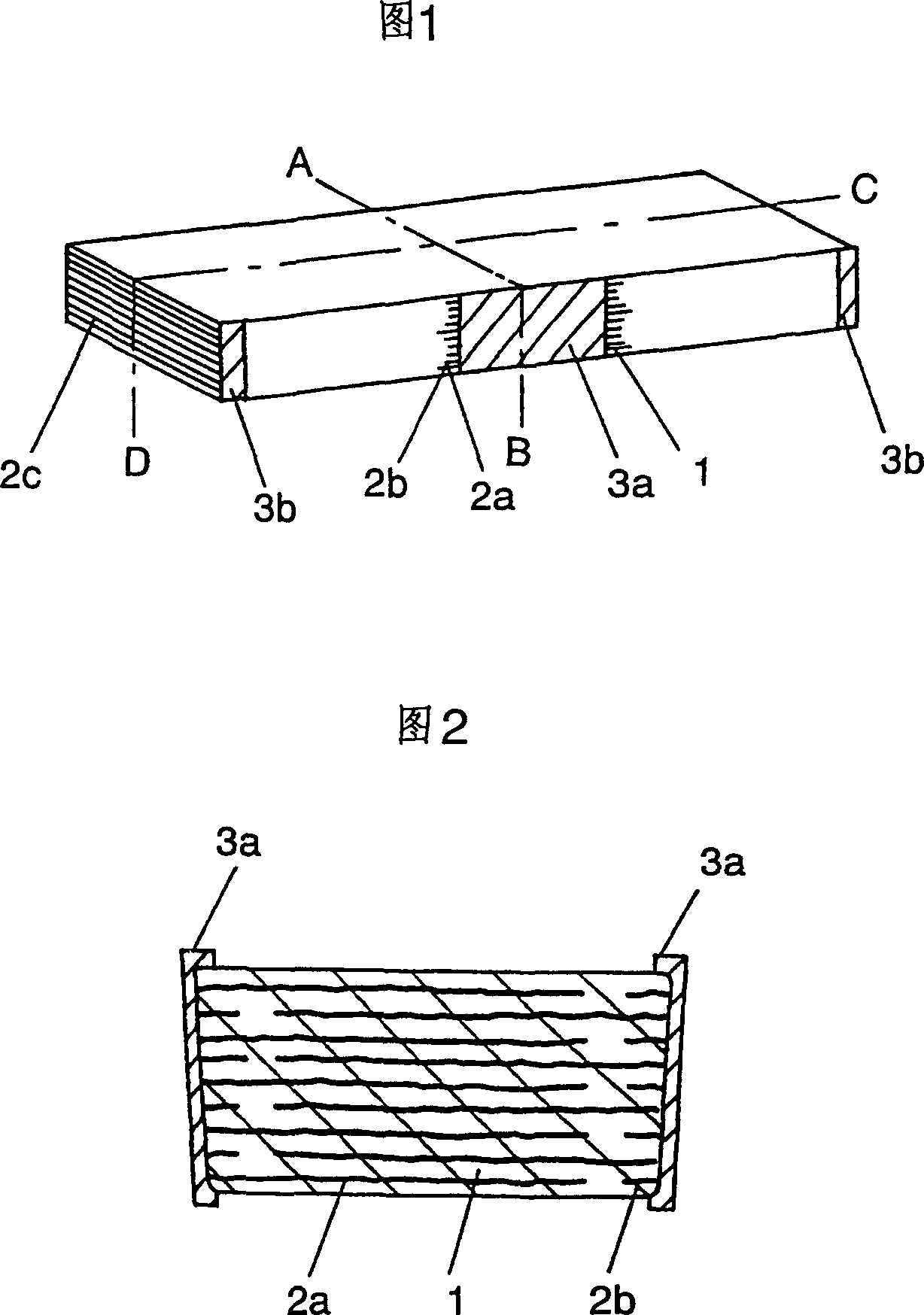

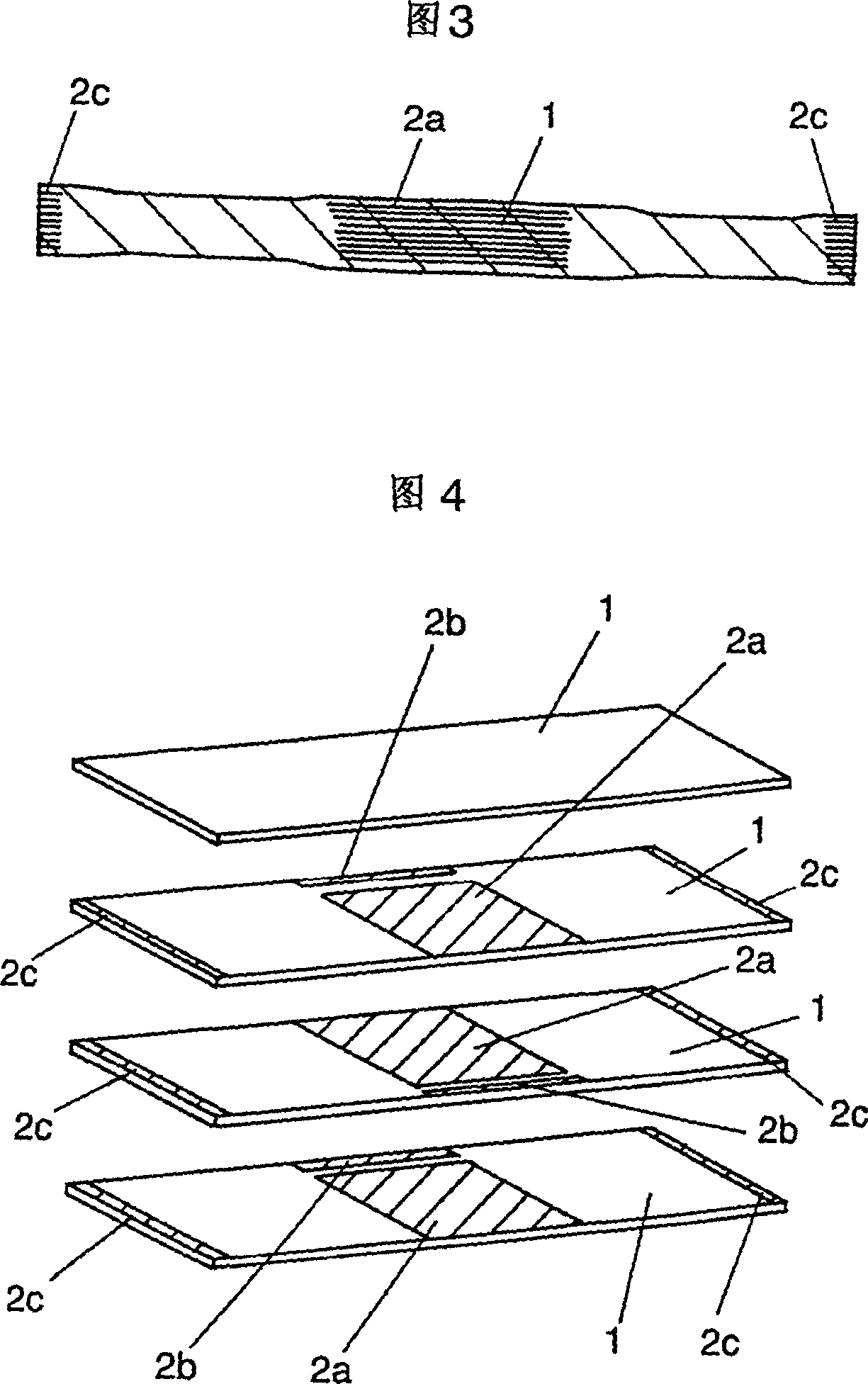

[0014] The manufacturing flow of the laminated piezoelectric transducer shown in FIG. 1 will be described with reference to FIGS. 2 to 5 .

Embodiment 1

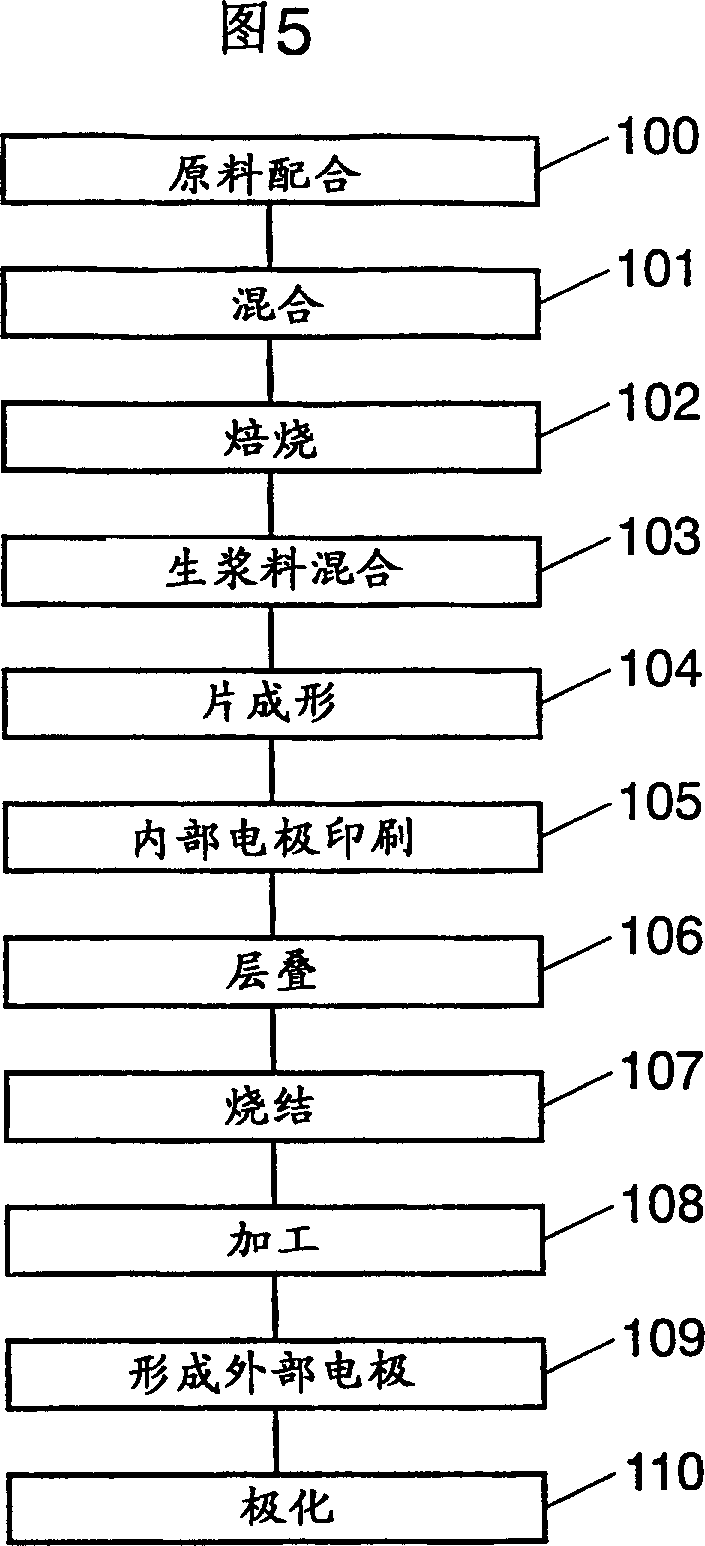

[0015] The multilayer piezoelectric transducer of Example 1 is composed of a ceramic layer 1, primary internal electrodes 2a and 2b, a secondary internal electrode 2c, a primary external electrode 3a, and a primary external electrode 3b. Its manufacturing method can be described based on the manufacturing flow chart shown in FIG. 5 .

[0016] First, PbO, ZrO, which are used in the manufacture of lead zirconate titanate-based piezoelectric materials, 2 、TiO 2 As the main material, auxiliary materials are added according to the specified ratio (step 100), and then mixed in the ball mill according to the set time (step 101).

[0017] Next, roast the mixed raw material powder (step 102), add organic binding material, plasticizer, and organic solvent in proportion, and carry out raw slurry mixing (step 103), and obtain the raw slurry for sheet forming.

[0018] Thereafter, the above-mentioned green slurry is applied by the doctor blade method to form a sheet (step 104), and a cer...

no. 2 Embodiment

[0028] Fig. 6 is a perspective view of a second embodiment of the laminated piezoelectric transducer. In Example 1, the external electrodes 3a and 3b were formed only on the side surfaces in the width direction of the laminate, but in this embodiment, the external electrodes 3a and 3b are provided not only on the side surfaces of the laminate but also on the upper and lower surfaces of the laminate.

[0029] According to the structure of this embodiment, the strength of the laminate increases as the adhesive strength between the laminate and the external electrodes 3a, 3b increases.

[0030] Furthermore, the existence of the external electrodes 3a, 3a also polarizes the ceramic layer 1 constituting the outermost layer on the upper and lower surfaces of the laminated body, thereby improving the boosting ratio. In consideration of increasing the boosting ratio, it is desirable to make the external electrodes 3a, 3b as large as possible on the surface of the laminated body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com