Bistable electromagnetic micro-mechanical relay

A micromechanical and bistable technology, applied in the direction of non-polar relays, etc., can solve the problems of high technical difficulty, open circuit impedance and breakdown voltage limitation, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

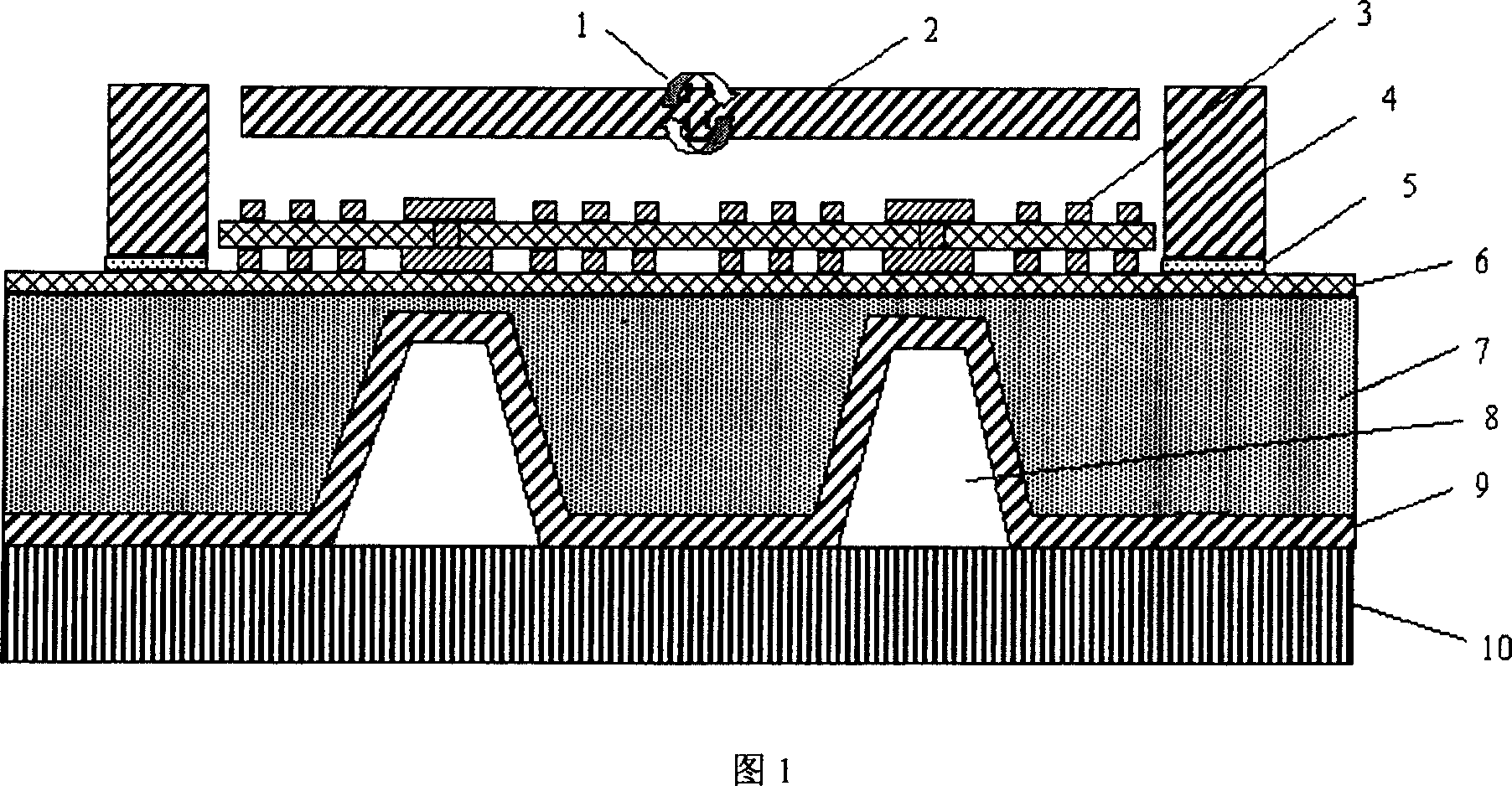

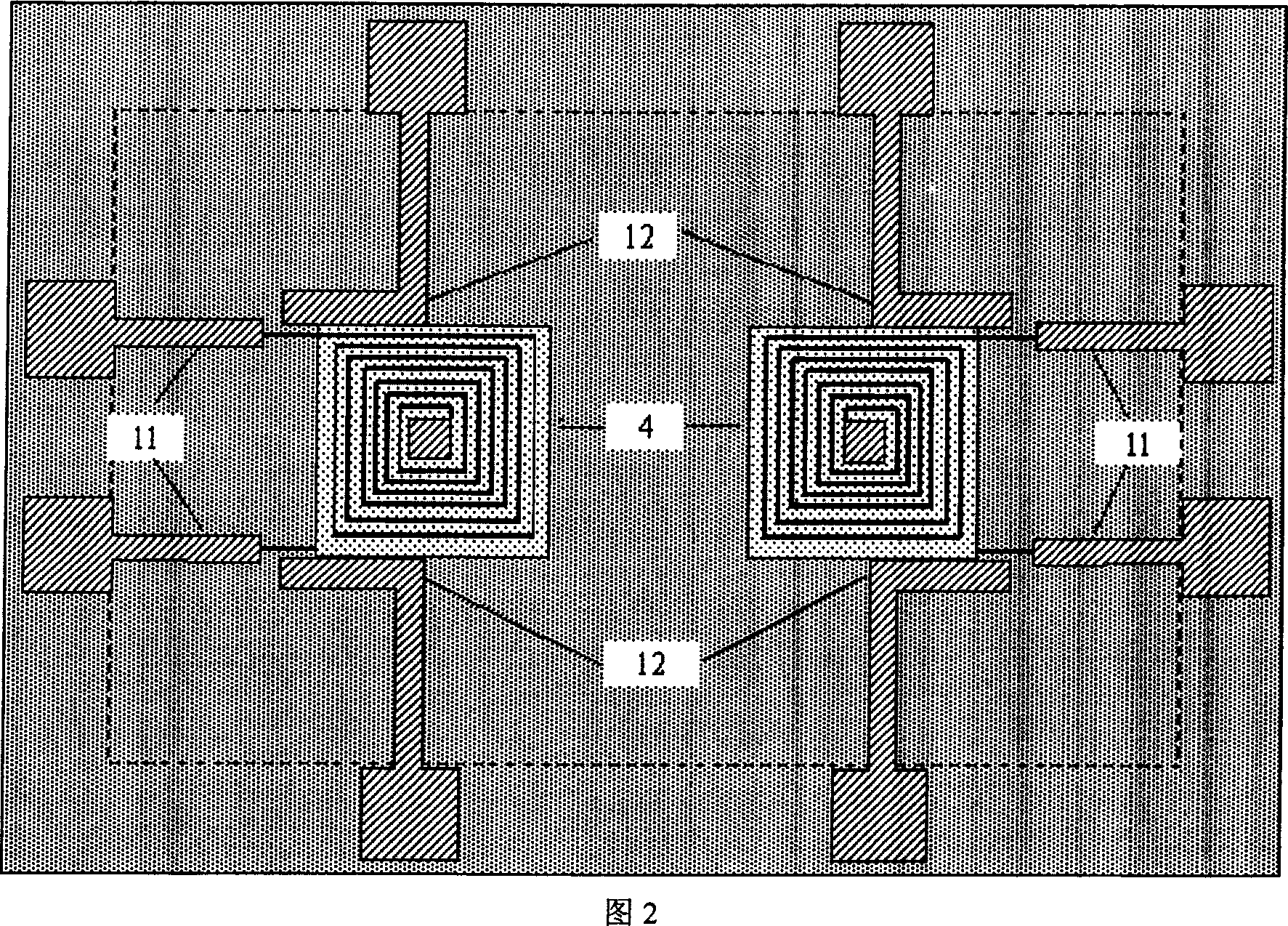

[0014] The structure of the bistable electromagnetic micromechanical relay is shown in Figure 1. It consists of a movable electrode system, a planar coil and a contact electrode system, a permalloy core and a permanent magnet.

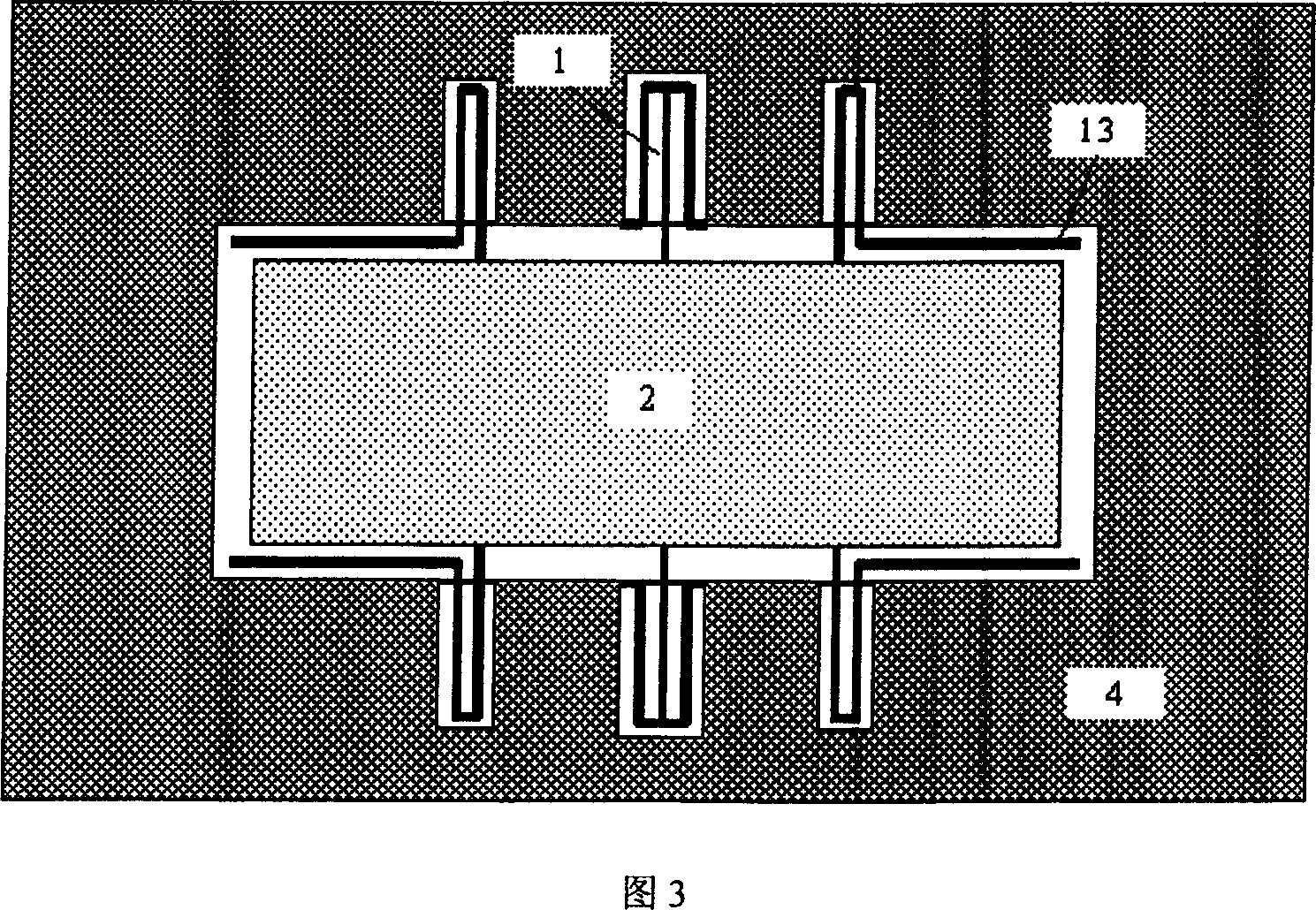

[0015] The structure of the movable electrode system is shown in Figure 3. It is composed of a movable electrode 2, a twisted beam 1, a contact 13 and a frame 4. The movable electrode 2 is supported on the frame 4 by the twisted beam 1 on both sides of the middle, and can be There are contacts 13 corresponding to the planar coil at both ends of the movable electrode 2, the movable electrode 2, the torsion beam 1 and the contact 13 have the same thickness, the thickness of the frame 4 is slightly thicker than that of the movable electrode 2, and the thickness difference will constitute The gap between the movable electrode 2 and the planar coil 3 . The whole movable electrode system is composed of silicon material coated with a layer of permalloy, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com