Flat plate type moderate temperature solid oxide fuel battery pile connecting component

A solid oxide, fuel cell stack technology, applied in fuel cell components, fuel cells, fuel cell grouping, etc., can solve the problems of decreased cell stack performance, single-cell cell stack seal damage, increased contact resistance, etc. Achieve improved feasibility and reliability, protection from contamination, and avoidance of oxidative corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

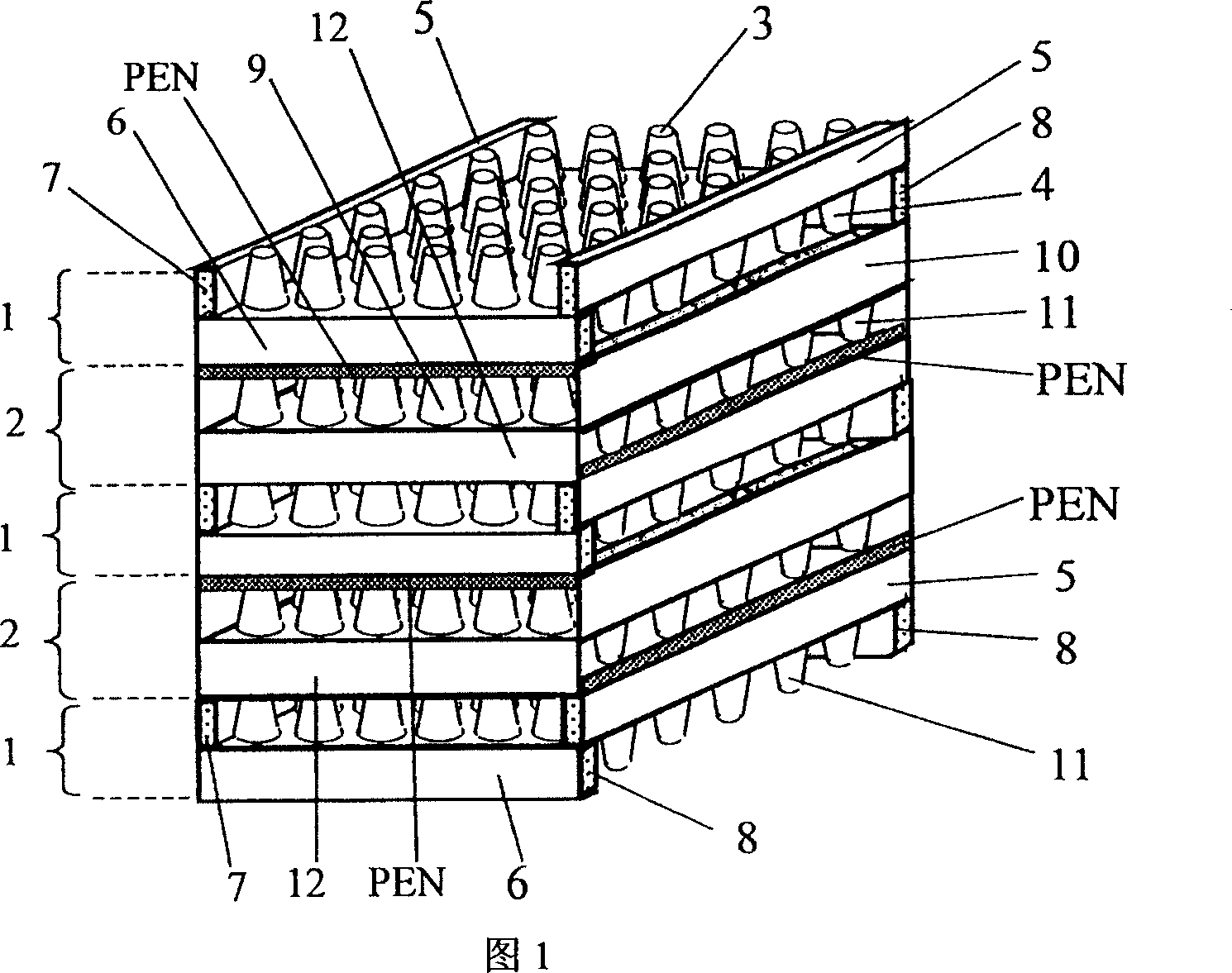

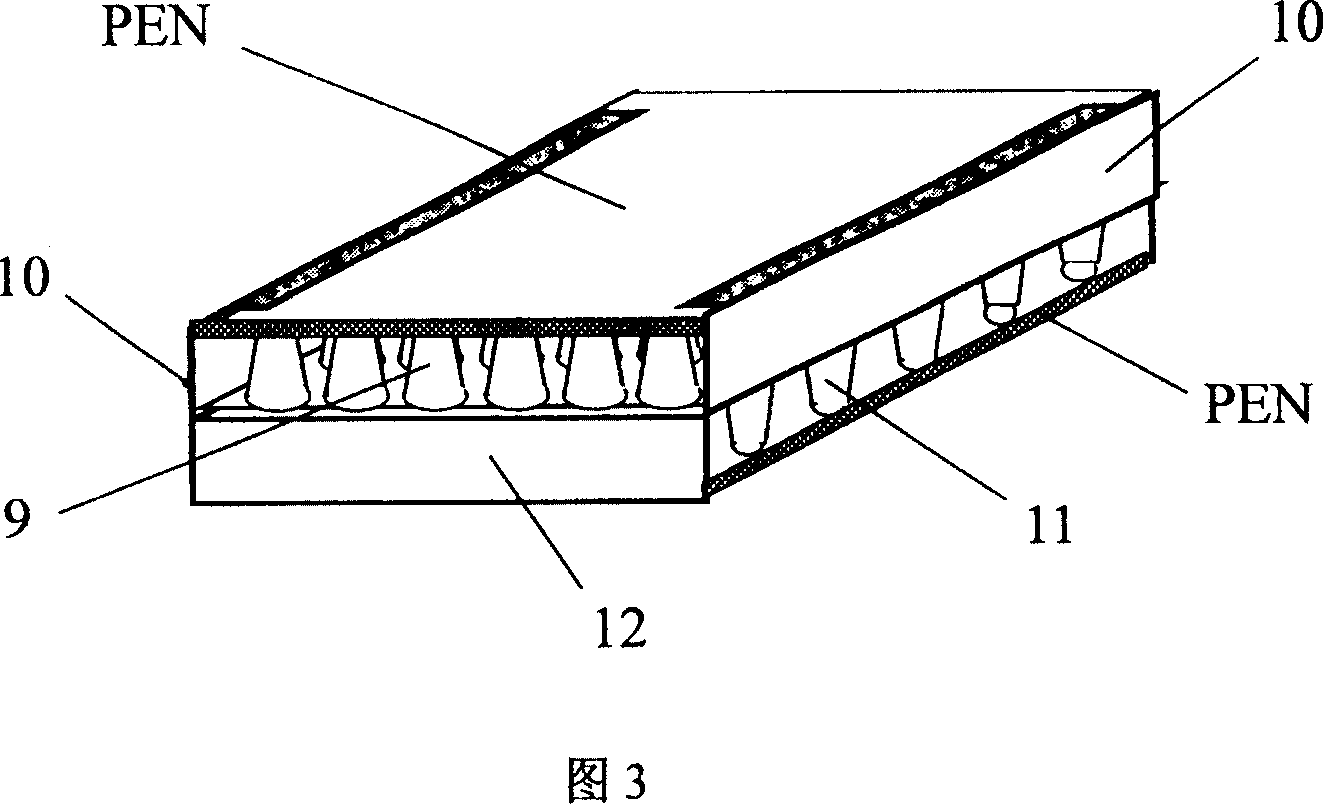

[0015] In this embodiment, Sm 0.2 Ce 0.8 o 2 (SDC) PEN supported by electrolyte layer, nominal area 50×50mm 2 , total thickness 0.5mm, La 0.65 Sr 0.35 co 0.2 Fe 0.8 o 3 The thickness of the cathode and Ni-SDC anode is about 50μm, and the four sides of the electrodes (cathode and anode) on both sides shrink inward by 3mm, that is, the effective area of PEN is 44×44mm 2 ; To build a 4-PEN battery stack. The production process is as follows:

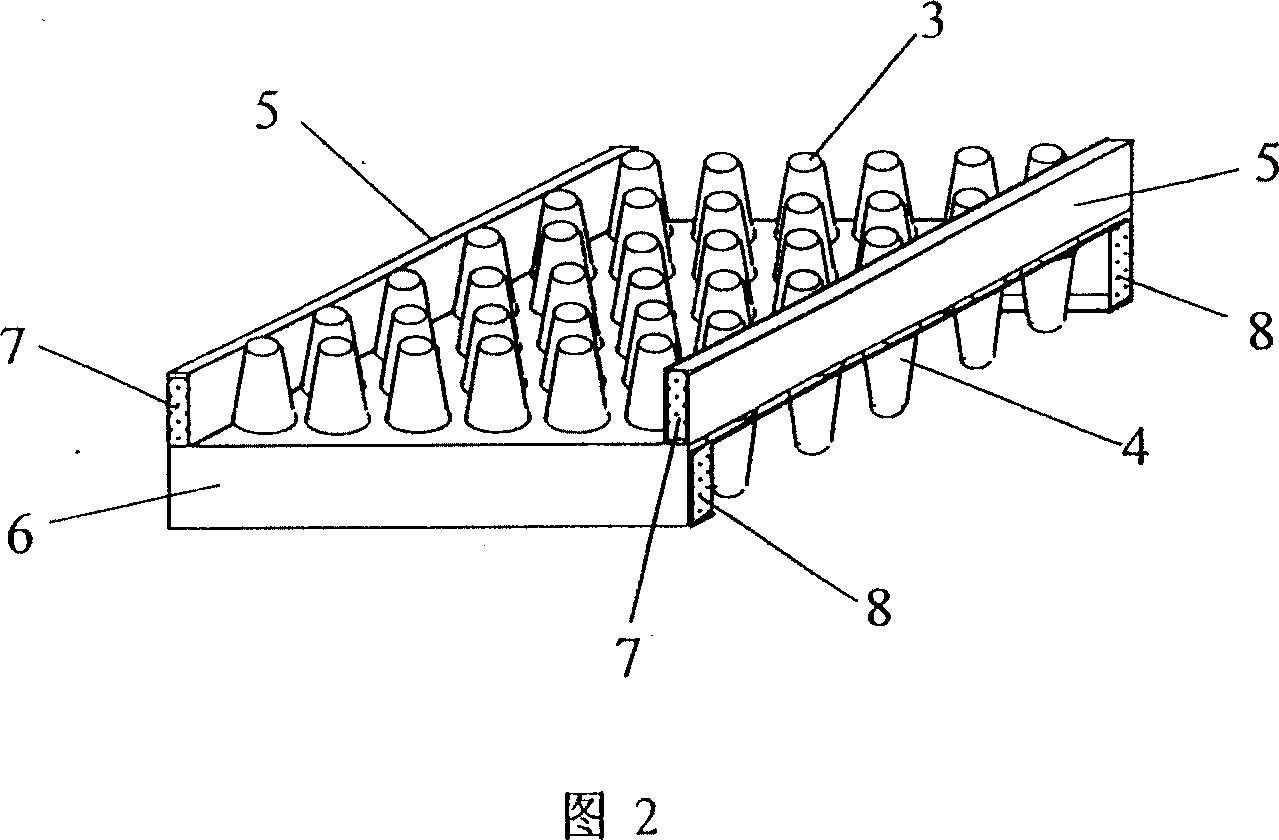

[0016] The first part 1 adopts a thickness of 0.2mm and an area of 60×60mm 2 Cut off a square copper plate and four corners of 5×5mm 2 square, middle 50×50mm 2 The square is used as the bottom of the upper U-shape, and 21 rows and 19 columns are evenly distributed on it to form an upper hollow round platform 3 protruding upwards by stamping. Use another piece with an area of 50×50mm 2 1. A square copper plate with a thickness of 0.2 mm is used as the lower U-shaped bottom of the first part 1. On the bottom, 19 rows and 21...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com