Frostiness detection method and unit for rubber product

A technology of rubber products and inspection methods, applied in the direction of material inspection products, etc., can solve problems such as company reputation damage, customer claims, returns, and frosting, so as to ensure quality and maintain goodwill, reduce the loss of wrong formulations, and reduce frosting. The effect of the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

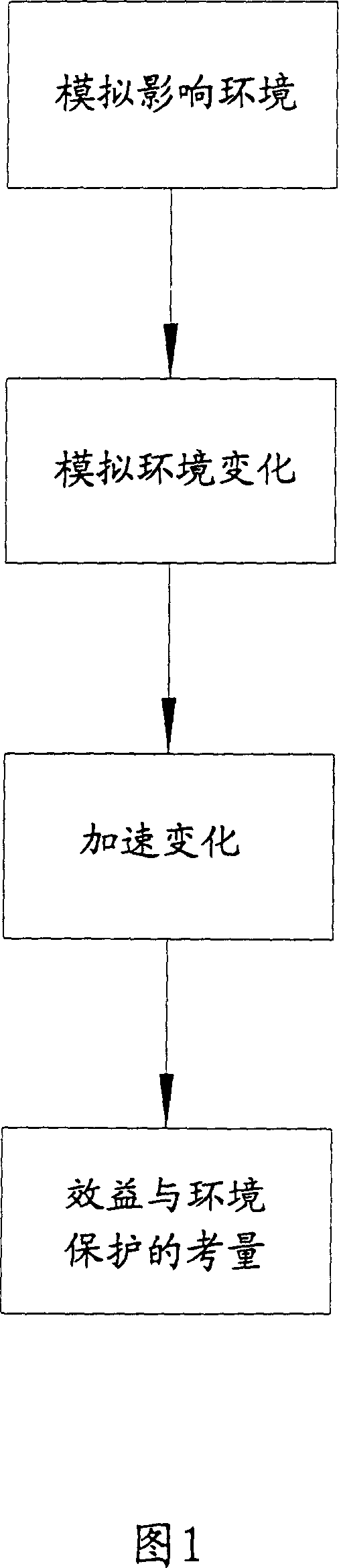

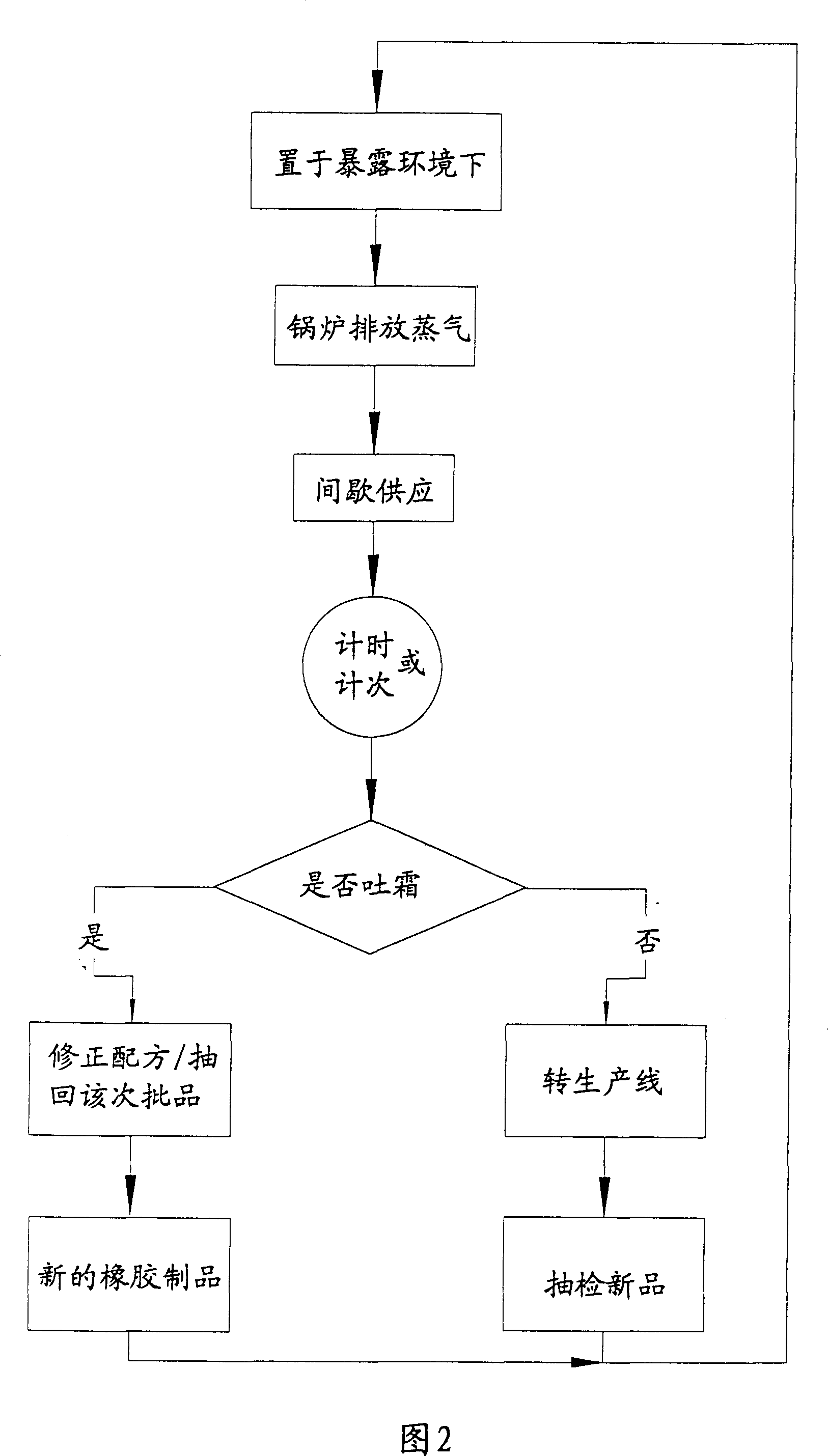

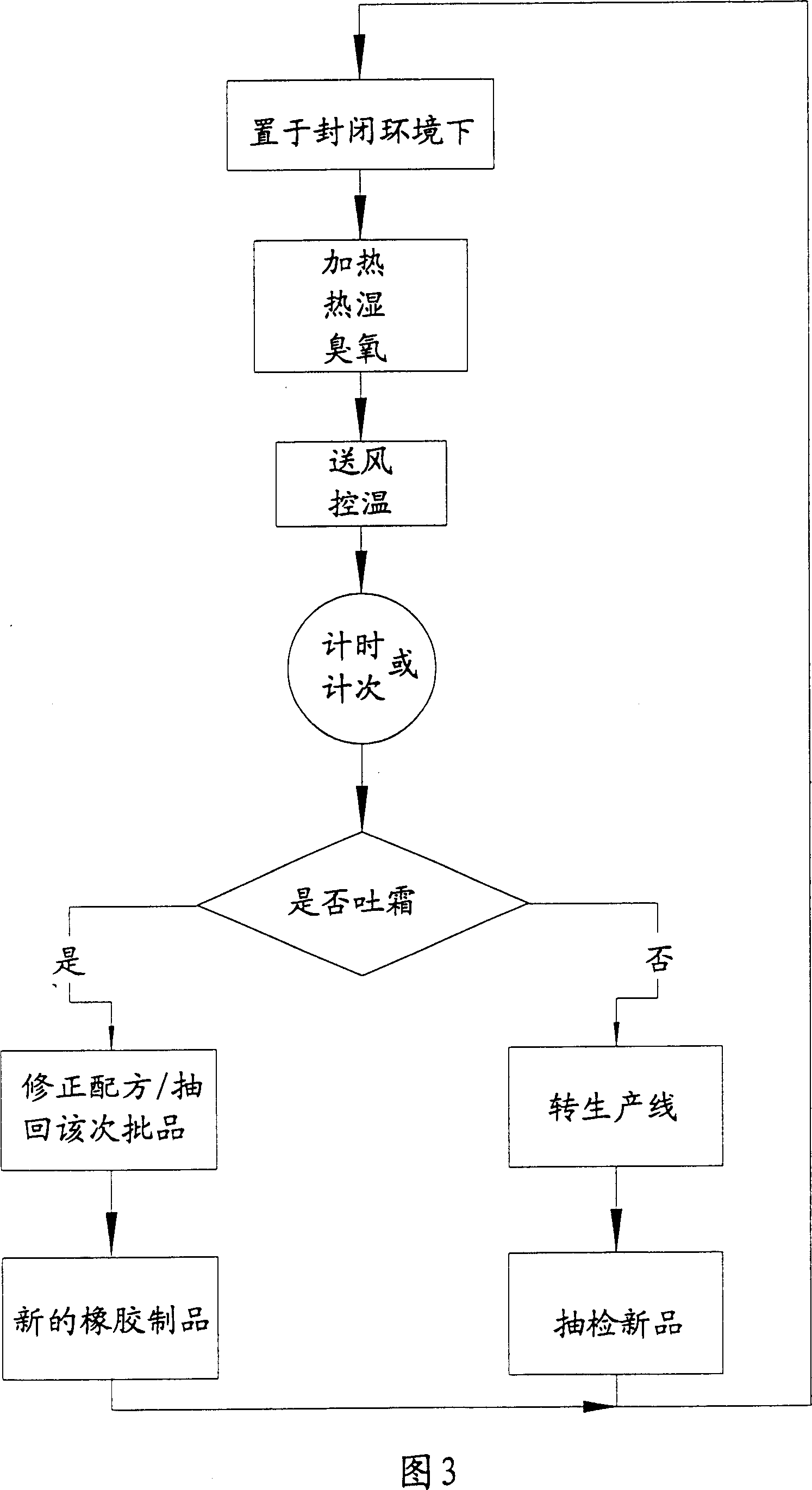

[0035] As shown in Figure 1, it is a block diagram of the rubber product frost test method of the present invention. The present invention simulates an impact environment (such as providing the impact factors of general environment: high temperature, high humidity and ozone, etc.), and then simulates the environment. Change (for example: provide control of temperature difference between day and night), and then accelerate the rate of impact (for example: enhance the strength of environmental influence factors - like providing higher temperature and providing supersaturated humidity, and increase the frequency of changes - like shortening the temperature difference between day and night change cycle or increase the number of changes within a certain period of time), and finally consider the necessity of economic benefits and environmental protection to select a better process, and the process flow of the aforementioned method is shown in Figure 2 and Figure 3. The process shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com