Micro mechanical switch of multiple resonance points

A micro-mechanical switch and multi-resonance technology, applied in relays, electrostatic relays/electro-adhesion relays, electrical components, etc., can solve problems such as narrow applicable bandwidth, and achieve the effect of improving resonance characteristics, excellent microwave performance, and expanding applicable frequency bands.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

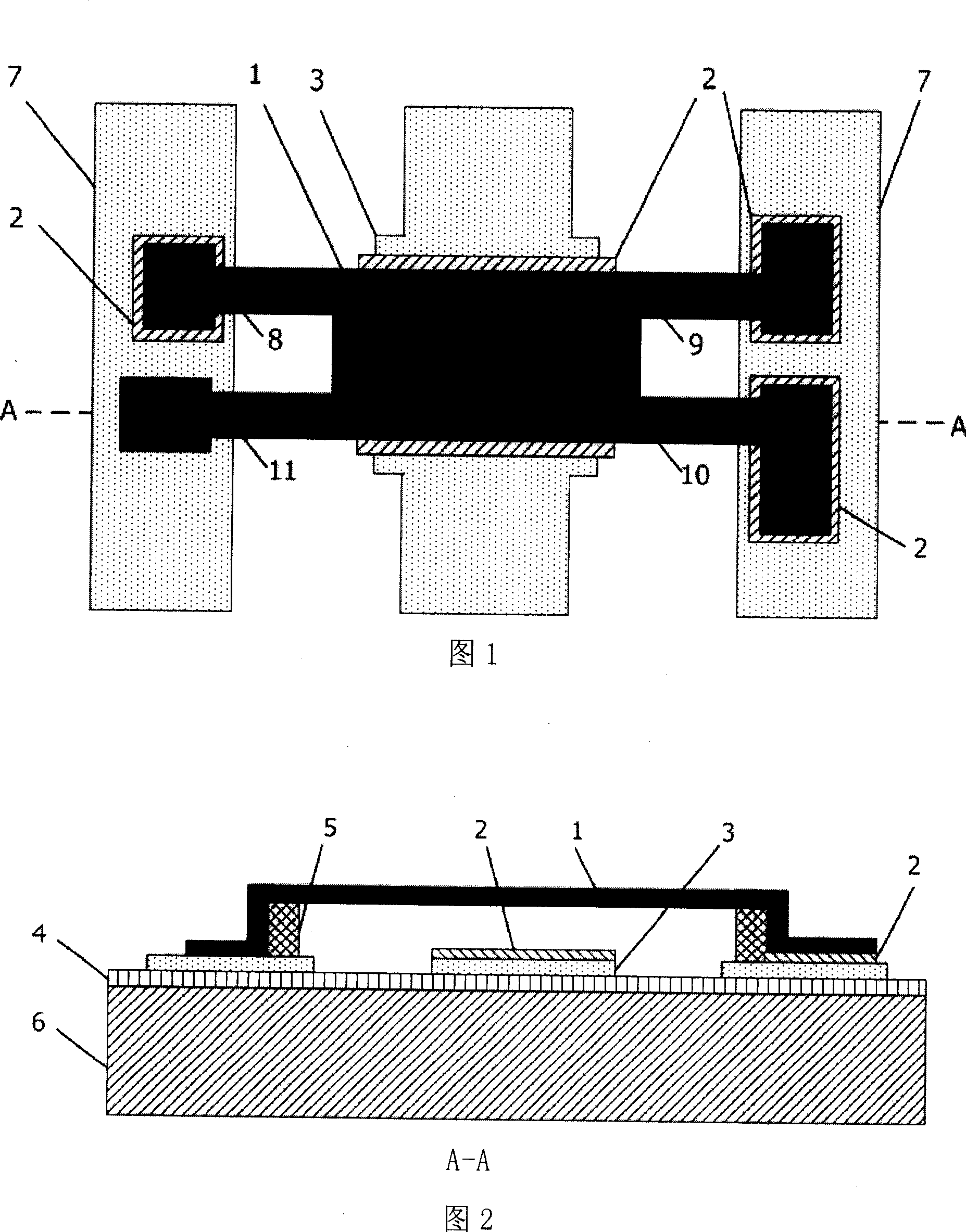

[0009] The invention provides a micromechanical switch with multiple resonance points. In the structural diagrams of the micromechanical switches shown in Fig. 1 and Fig. 2, there are an oxide layer 4, a lower plate 3 and a silicon nitride layer 2 on the silicon substrate 6 from bottom to top, and the sacrificial layer 5 is formed on top of the silicon nitride layer. The upper electrode 1 is supported on the layer 2, and there are more than one metal connection beams 8, 9, 10 or 11 between the upper electrode 1 and the ground wire 7, at least one beam 11 is directly grounded, and the rest of the non-ground beams are connected to the ground wire. The silicon nitride layer is connected or suspended to form a ground capacitance; the connecting beam adopts a straight beam, a folded beam or a folded spring structure to increase the equivalent inductance; by adjusting the direct facing area of the non-grounded beam and the ground wire, or the medium between the two thickness, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com