Electrode and slot number matching of wheel motor and rule structure therefor

A technology of wheel motor and the number of slots per pole, applied in the shape/pattern/structure of the motor, winding conductor, magnetic circuit shape/pattern/structure, etc. Difficulties in processing, assembly and other problems, to achieve the effect of neat winding ends, high slot full rate, and convenient end finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention are shown in the accompanying drawings. The present invention will be further described below in conjunction with accompanying drawing.

[0010] First of all, attached table 1 gives examples of some possible combinations of pole slot numbers in the present invention, where those marked with * are recommended pole slot number combinations.

[0011] Since the slot pitch in the present invention is fixed to 1, the two sides of a coil are respectively embedded in adjacent slots,

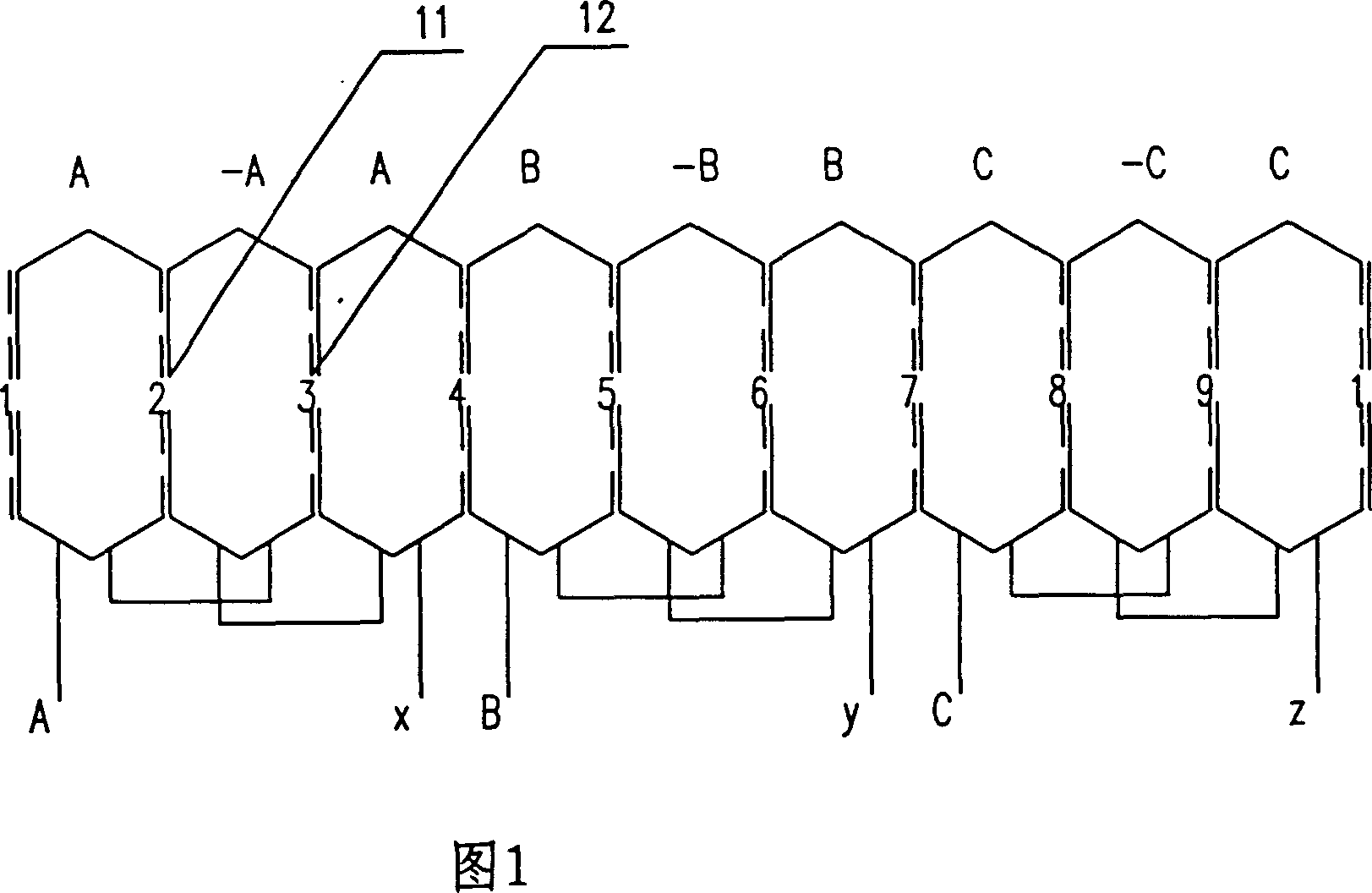

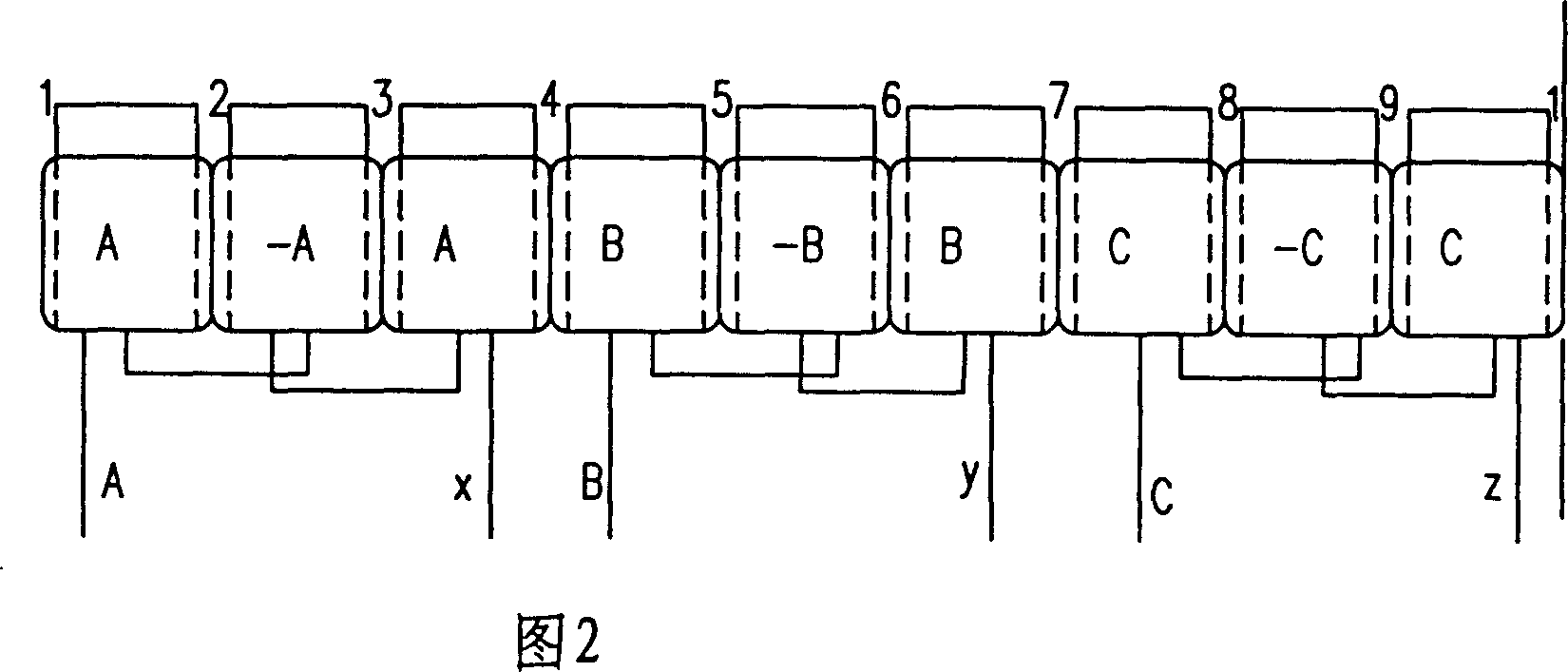

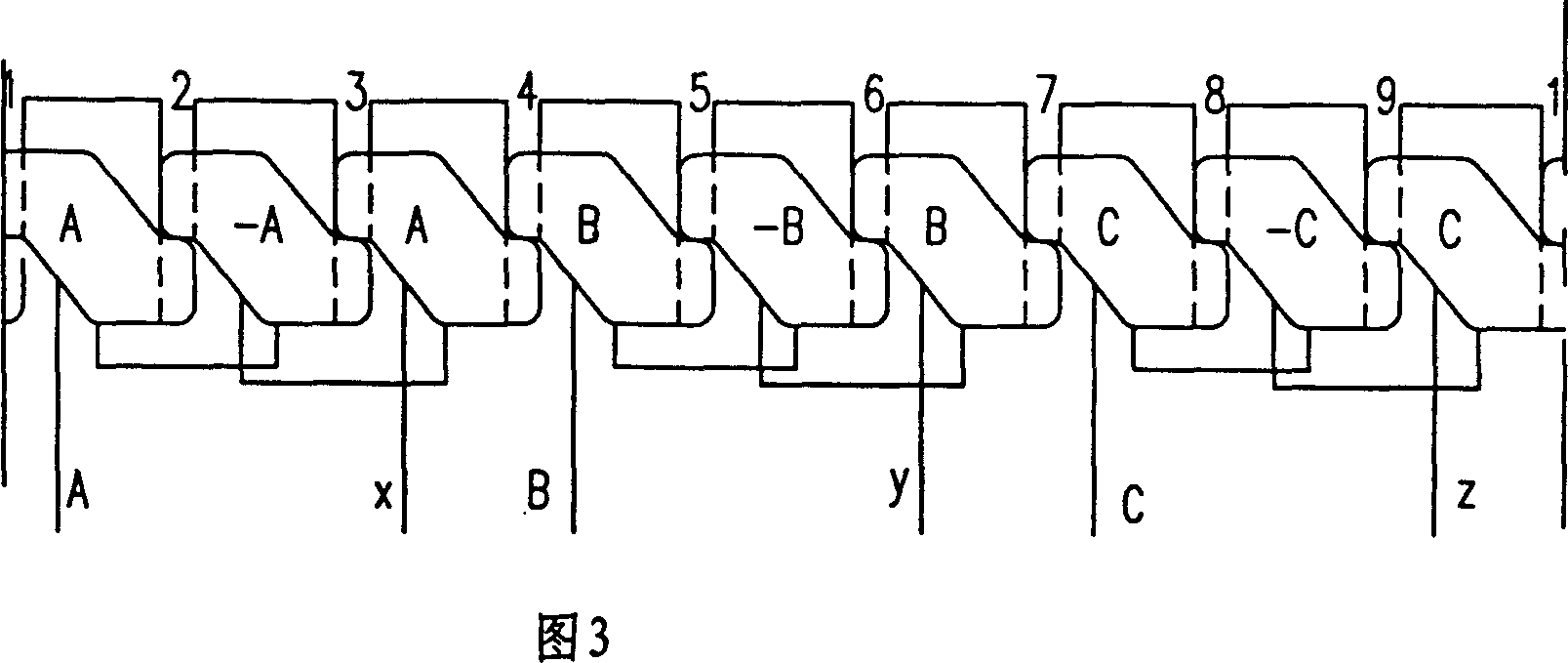

[0012] The number of poles and slots of the embodiment shown in Fig. 1 is matched with 3 phases, 8 poles and 9 slots. As can be seen from the figure, the numbers 1, 2, 3, 4, 5, 6, 7, 8, and 9 in the figure are slot numbers, the solid line 11 indicates the starting side of the coil, the dotted line 12 indicates the ending side of the coil, and the letter A on the top , B, and C indicate the phase to which the coil belongs, the negative sign indicates that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com